ZMT Owner’s Manual

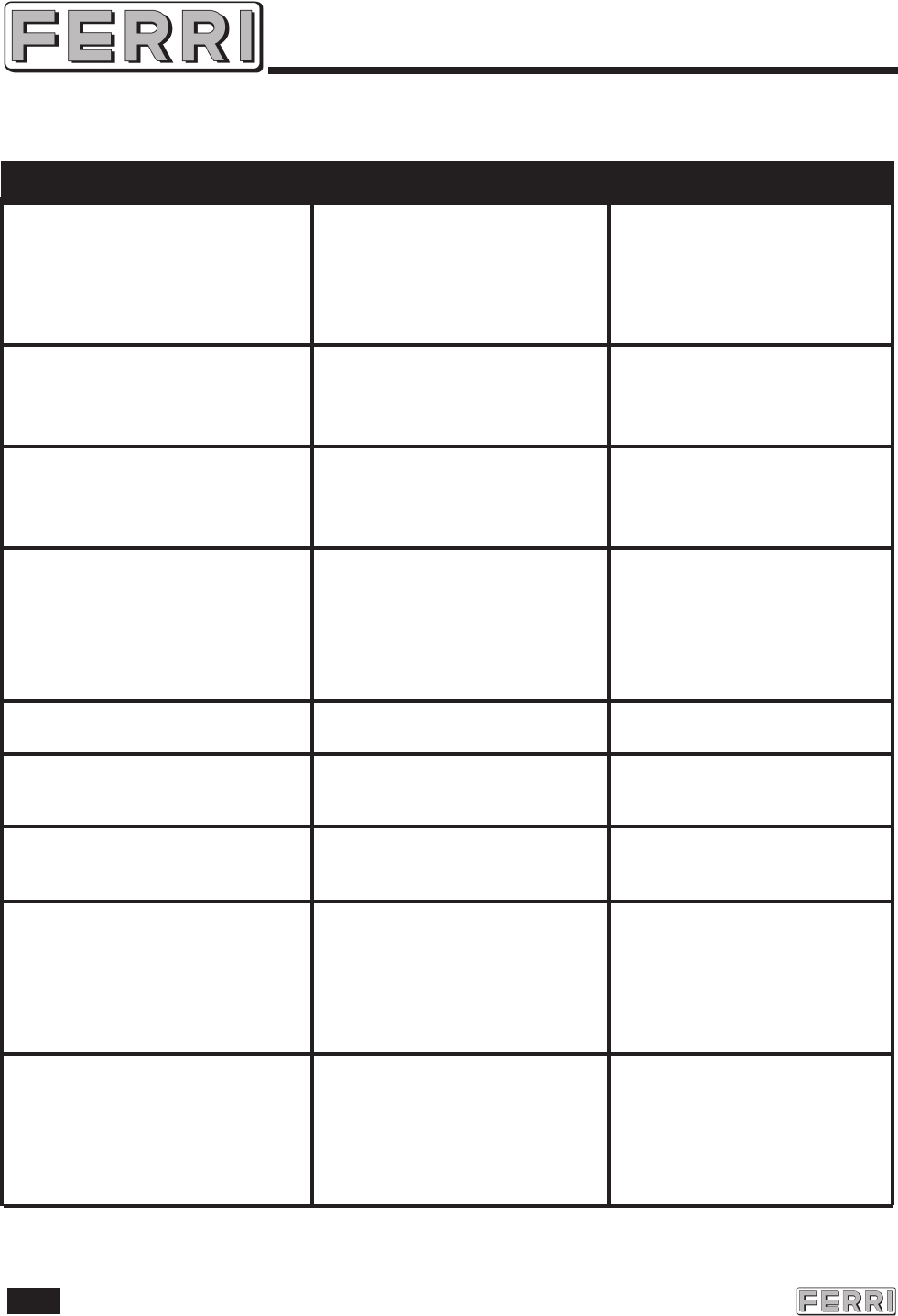

8. TROUBLE SHOOTING CHART

PROBLEM CAUSE FIX

17

Irregular cut

Machine noise

Gearbox noise

Vibration

Premature flail wear

Excessive backlash in the

arms & joints

Flail head lowers

involuntarily

Breakage of roller bearings

Belts overheating

• Worn, bent or broken fails

• Machine is not level with

the ground

• Clogged material due to

excessive working speed

• Loose bolts

• Cracks or initiation of flail

head

• Lack of oil

• Worn gears

• Worn bearings

• Broken or worn flails

• Unbalanced rotor

• Worn rotor bearings

• Flails touching the ground

• Worn pins

• Worn arm sliding blocks

• Worn glands in the rams

• Violent impact on the

ground when the arm is

lowered

• Dirty or little greased

bearings

• Flails touching the ground

• Working speed unsuitable

for amount of the material

to cut

• Belts slip on the pulleys

• Replace

• Level it by adjusting the

flail head hydraulic ram

• Reduce working speed

• Tighten bolts

• Have it repaired in

specialized workshop

• Fill to level

• Replace

• Replace

• Replace

• Have it replaced in

authorized workshop

• Have them replaced in

authorized workshop

• Adjust height of cut

• Replace

• Adjust

• Replace glands in

authorized shop

• Lower it gently

• Clean and grease

• Adjust cut height

• Reduce speed

• Adjust belt tension

18