- 28 -

clearance to ground.

Do

Not

adjust rollers to support the deck. Be sure

roller bolts and nuts are installed with the spring disc washer between

head of bolt and mounting bracket.

Torque to 40-45 ft-lbs., or loss of

roller may result

.

c) When operating in extremely rough conditions it may be necessary to

position the anti-scalp rollers one or two holes higher than described in

"b" to prevent damage to the rollers and/or bolt failure(See Figure 14).

NOTE:

When anti-scalp rollers are placed in these positions, reduced

deck flotation will result.

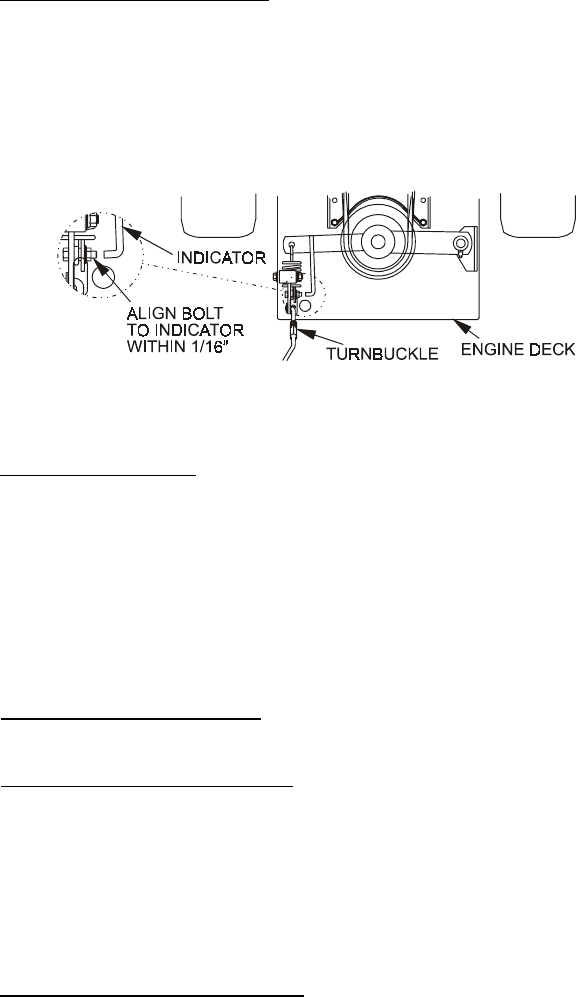

5.2.2 Blade engagement Linkage: Located between the blade engagement lever on

the left handle and the left rear corner of the engine deck.

a) Stop engine and remove spark plug wire(s).

b) With blade drive engaged, adjust the linkage length by loosening the

locknut on the turnbuckle and adjusting the turnbuckle so that the bolt on

the bellcrank and the indicator arm align with each other within 1/16”.

See Figure 15. Tighten locknut against turnbuckle.

FIG. 15

BLADE ENGAGEMENT LINKAGE

5.2.3 Blade Safety Switch:

a) Stop engine and remove spark plug wire(s).

b) With blades disengaged and the bellcrank touching the rear of the slot in

the engine deck, adjust the blade safety switch (if needed) until the

bellcrank arm is 5/16” from the switch body.

c) Be sure the bellcrank

DOES NOT

touch the switch body or damage to the

switch could occur.

d) Retighten blade switch mounting hardware.

5.2.4 Engine to Cutter Deck Belt:

No adjustment necessary

.

5.2.5 Transmission Belt Adjustment:

a) Stop engine and remove spark plug wire(s).

b) To tighten transmission belt, loosen the 3/8” nyloc nut on transmission

belt idler pulley. Slide bolt inward in slot and retighten nyloc nut.

c) When properly adjusted, the belt should have 1/2” of deflection with three

pounds of pressure on the belt midway between the transmission and

engine pulley.

5.2.6 Wheel drive belts and scrapers:

a) If wheel traction appears to be slipping, drive lever rods may be touching

bottom of neutral lock/park brake latch slot. To adjust, refer to directions

in Section 3.11

NOTE: Wheel drive springs have three tension settings. Refer to Section

5.2.11.