11

n) Re-install the seal guards over the wheel hub and insert wheel into caster fork.

Re-install caster bolt and tighten nut fully.

IMPORTANT: To prevent seal and bearing damage, check the bearing

adjustment often. Spin the caster tire. The tire should not spin freely (more

than 1 or 2 revolutions) or have any side play. If the wheel spins freely, adjust

torque on spacer nut until there is a slight amount of drag. Re-apply thread

locking adhesive.

c) Lubricate switch actuator rod with spray type lubricant or light oil.

4.2.7 Change gearbox oil:

Change oil in all 3 gearbox housings after first 50 hrs of operation. Check

every 100 hours thereafter. Add oil as needed until level with oil drain plug.

a) Stop engine, wait for all moving parts to stop, and remove key.

b) Place unit on a level surface.

c) Remove the gearbox and drive shaft assembly from the mower deck. Retain

hardware for re-use.

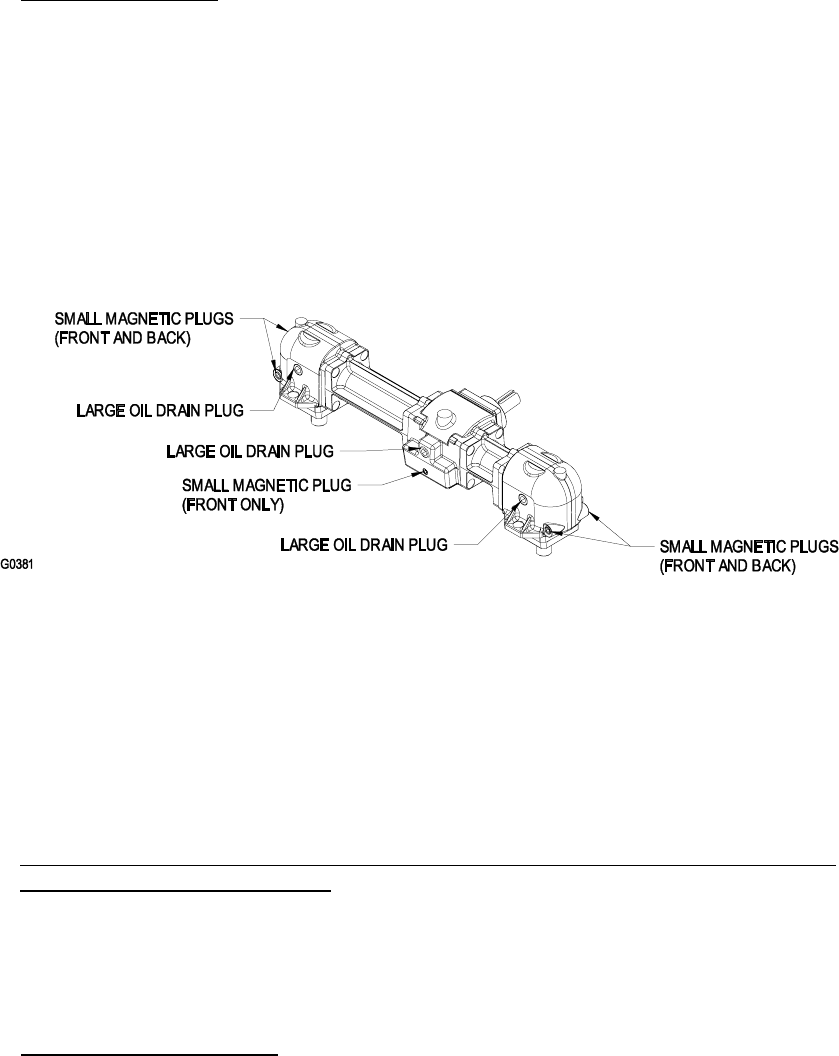

d) Remove the large oil drain plug on the front of each of the 3 gearboxes and drain

oil. See Figure 9.

e) Remove small magnetic plugs and wipe away any material accumulated on the

plugs. See Figure 9.

FIGURE 9

GEARBOX OIL DRAIN LOCATIONS

f) Apply a Teflon pipe sealant to all small magnetic plugs and re-install into the

gearbox.

g) Re-install the gearbox and drive shaft assembly to the mower deck.

h) Fill gearbox with Mobil 1 75W-90 gear lube oil until level with oil drain plug.

NOTE: Mower deck should remain level to the ground when filling gearbox with oil.

Do not fill gearbox with deck raised in the service position.

i) Apply a Teflon pipe sealant to the 3 large oil plugs and re-install into the gearbox.

4.2.8 Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut Type” are

used on the following fasteners:

a) Caster wheel spacer nuts.

4.3 ADJUSTMENTS

IMPORTANT: Disengage PTO, shut off engine, wait for all moving parts to stop, and

remove key before servicing, cleaning, or making any adjustments to the unit.

4.3.1 Cutting Height Adjustment

:

a) Stop engine, wait for all moving parts to stop, and remove key.

b) Move cotter pins on four deck support pins to proper hole for height of cut

desired.