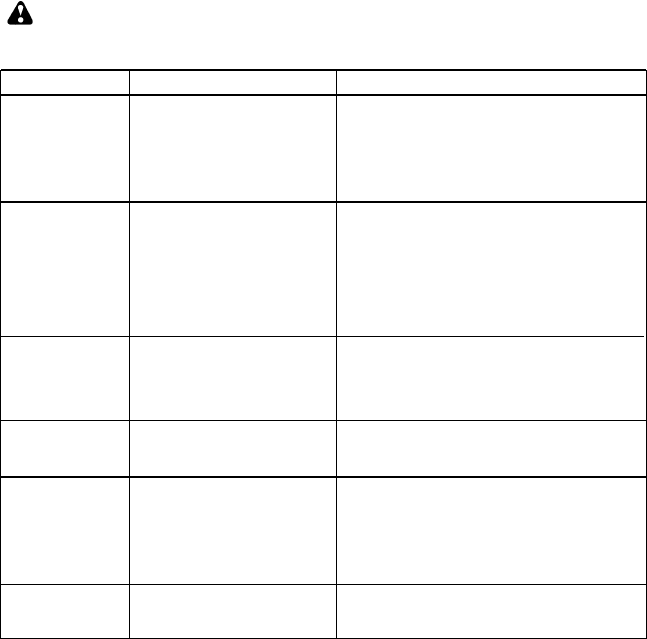

7

TROUBLE CAUSE REMEDY

Semi-automatic

head stops

under a load or

does not turn

when switch is

pressed.

1. Allow tip of line to do the cutting.

2. Contact your authorized ser vice dealer.

3. Check Breaker Box.

4. Remove debris.

Line does not

advance or

breaks while

cutting.

1. Check line routing.

2. Rewind line tightly and evenly.

3. Use only .065 in. (1.65mm) dia. line.

4. Remove cover and pull 4 in.

(10 cm) of line out of head.

5. Clean unit.

Line welds onto

spool.

1. Use only .065 in. (1.65mm) dia. line.

2. Replace with correct spool.

3. Cut with tip of line fully extended.

Line releases

continuously.

1. Check line routing.

2. Replace spool.

Line pulls back

into head.

1. Too little line outside

of head.

2. Line size incorrect.

1. Remove cover and pull 4 in.

(10 cm) of line outside of head.

2. Use only .065 in. (1.65 mm) dia. line.

TROUBLESHOOTING TABLE

1. Line improperly

routed in head.

2. Spool damaged.

1. Line size is incorrect.

2. Incorrect spool.

3. Line is being crowded

against material being

cut.

1. Line improperly routed

in head.

2. Line improperly

wound onto spool.

3. Incorrect line size

4. Not enough line

outside of head.

5. Dirt buildup on unit.

1. Crowding trimmer line

against material being

cut.

2. Electrical failure.

3. Thrown circuit breaker.

4. Debris stopping head.

Line usage is

excessive.

1. Check line routing.

2. Replace spool.

3. Cut with tip of line fully extended.

4. Replace spool.

1. Line improperly routed

in head.

2. Line size is incorrect.

3. Crowding line against

material being cut.

4. Spool worn or damaged.

WARNING:

Alwaysstop unitanddisconnect fromthe powersource before

performing all ofthe recommended remedies belowexcept remedies that re-

quire operation of the unit.