10

ASSEMBLY

PLASTIC

SHIELD INSTALLATION

(Nylon line operation)

Tools Required: Screwdriver, Locking Tool

Parts Required: Plastic Debris Shield, Shield Plate,

three (3) 5 x 16 mm screws.

WARNING DANGER

The plastic shield is for use with the Nylon Line Head only. Install

Metal Shield when using plastic or metal blades, or serious injury

may result.

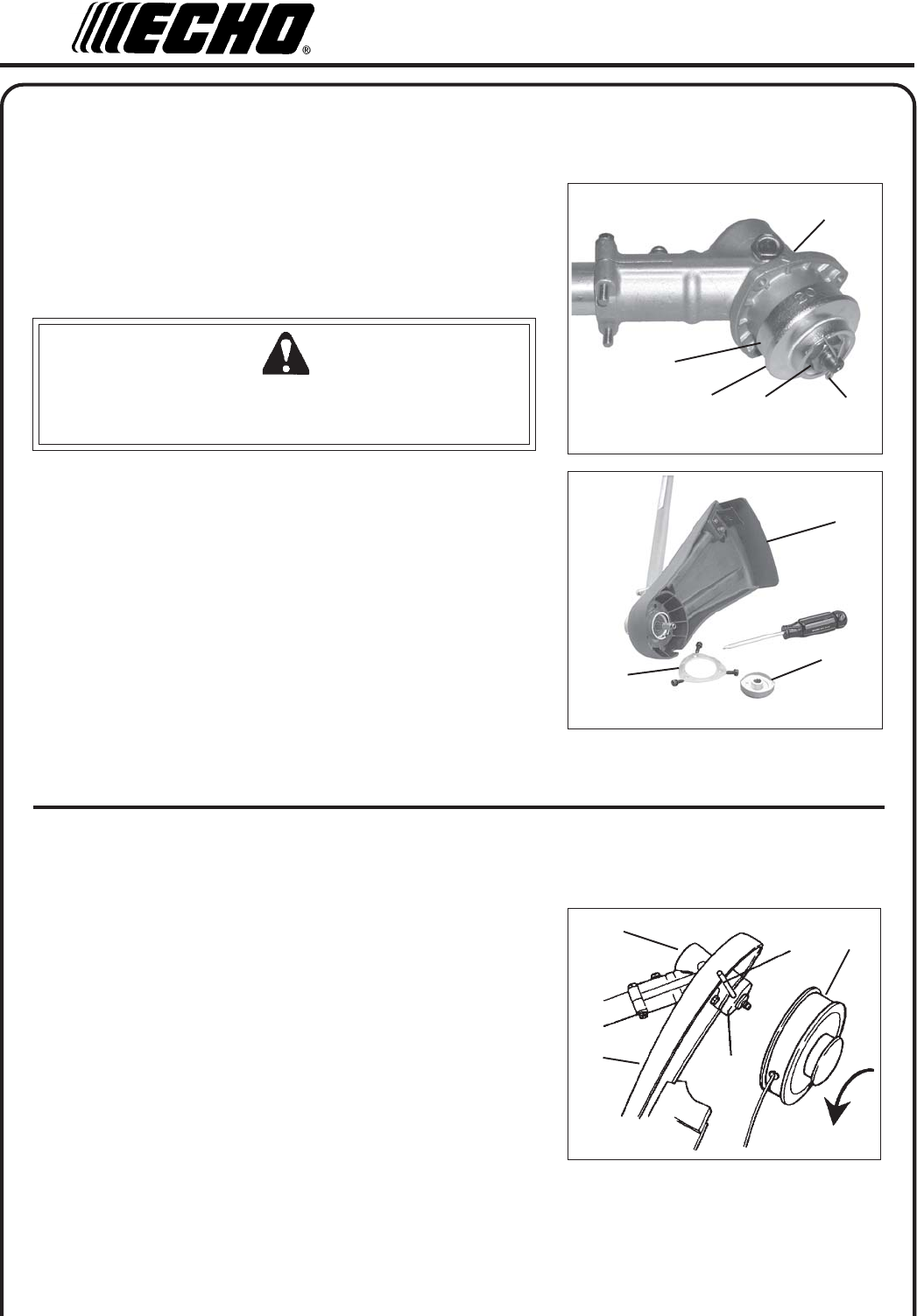

1. Align hole in upper plate (D) with notch in gear housing (G), and

insert locking tool to prevent splined shaft from turning. Arrow on

gear housing flange points to notch location.

2. Remove cotter pin (A), L.H. blade nut (B), lower plate (C), and

upper plate (D) from PTO shaft. Turn blade nut clockwise to

remove.

3. Remove locking tool. Retain lower plate, blade nut, and cotter pin

for future use with blade conversions.

4. Align plastic debris shield (F) with the drive shaft, and install on

the bottom of the gear housing flange.

5. Place shield plate (E) on shield, align holes and install three (3)

screws.

6. Replace upper plate (D) on PTO shaft.

E

D

F

C

B

A

D

G

NYLON LINE HEAD INSTALLATION

Tools Required: Locking Tool, 17x19 mm Wrench

Parts Required: Nylon Line Head.

1. Make sure plastic debris shield (F) is properly aligned, and upper

plate (D) is installed on splined PTO shaft.

2. Align hole in upper plate (D) with notch in gear housing (G), and

insert locking tool (H) to prevent splined shaft from turning.

3. Thread line head (I) onto PTO shaft by turning it counter-clockwise

until head is tight against upper plate (D).

4. Remove locking tool.

H

D

G

F

I