15

MAINTENANCE AND CARE

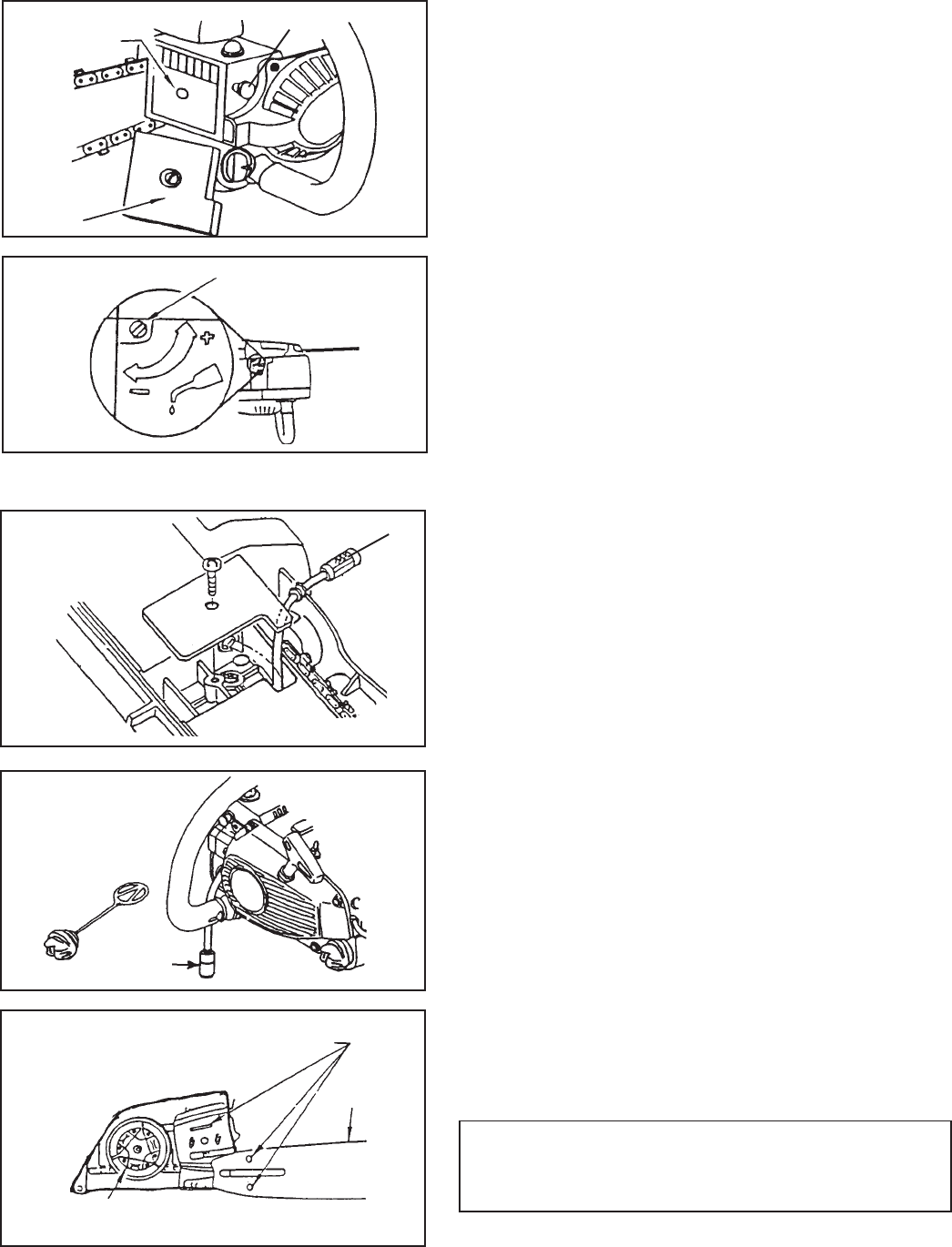

AIR FILTER

• Check before every use.

• Pull choke (A) all the way out (close position).

• Loosen bolt and remove air cleaner (B) cover and filter (C).

• Lightly brush dust off filter, and inspect for damage.

A

B

C

D

E

F

G

H

J

AUTOMATIC OILER

• The discharge volume of the automatic oiler is adjusted to 3

to 4 cc/mm (@ 7000 rpm) prior to shipment from the factory.

• Always check oil discharge when in use.

• Turn adjusting screw (D) counter-clockwise to increase oil

volume, clockwise to decrease oil volume.

OIL STRAINER

• Check periodically.

- Do not allow dust to enter into oil tank.

- Clogged oil strainer will affect the normal lubricating

system.

- Pick it up through oil port.

- If the strainer (E) is dirty, wash it in gasoline.

- When the inside of the tank gets dirty, rinsing the tank

out with gasoline will clean it.

FUEL STRAINER

• Check periodically.

- Do not allow dust to enter fuel tank.

- Clogged strainer will cause difficulty in starting engine or

abnormalities in engine performance.

- Pick up the fuel strainer (F) through fuel inlet port with a

piece of steel wire, or the like.

- When the strainer is dirty, wash it in suitable cleaning

fluid.

- When the inside of the fuel tank is dirty, rinsing the tank

out with suitable cleaning fluid will clean it.

GUIDE BAR AND OIL HOLES

• Clean after each use

- Clean the grooves (G) of the guide bar with, for example,

a small screwdriver.

- Clean oil holes (H) with a wire.

• Reverse guide bar periodically.

SPROCKET

• A damaged sprocket (J) will cause premature damage or

wear of saw chain.

- When the sprocket has worn out 0.5mm (.020”) or more,

replace it.

• Check sprocket when you install new chain. Replace it if

worn.

• Clean sprocket, clutch and bar mount area before installation

of bar.

IMPORTANT

Some tree sap and resins are corrosive. Thoroughly wash the

guide bar and sprocket areas after each use, then coat metal

parts with light oil.