17

CS-1201

1

3

4

5

NOTE

These angles are referred to as Oregon 27 saw chain.

For other branded saw chain, follow it’s chain

manufacturer’s instruction.

Parallel

A

30°

BC

60°

D

0.76 mm

85°

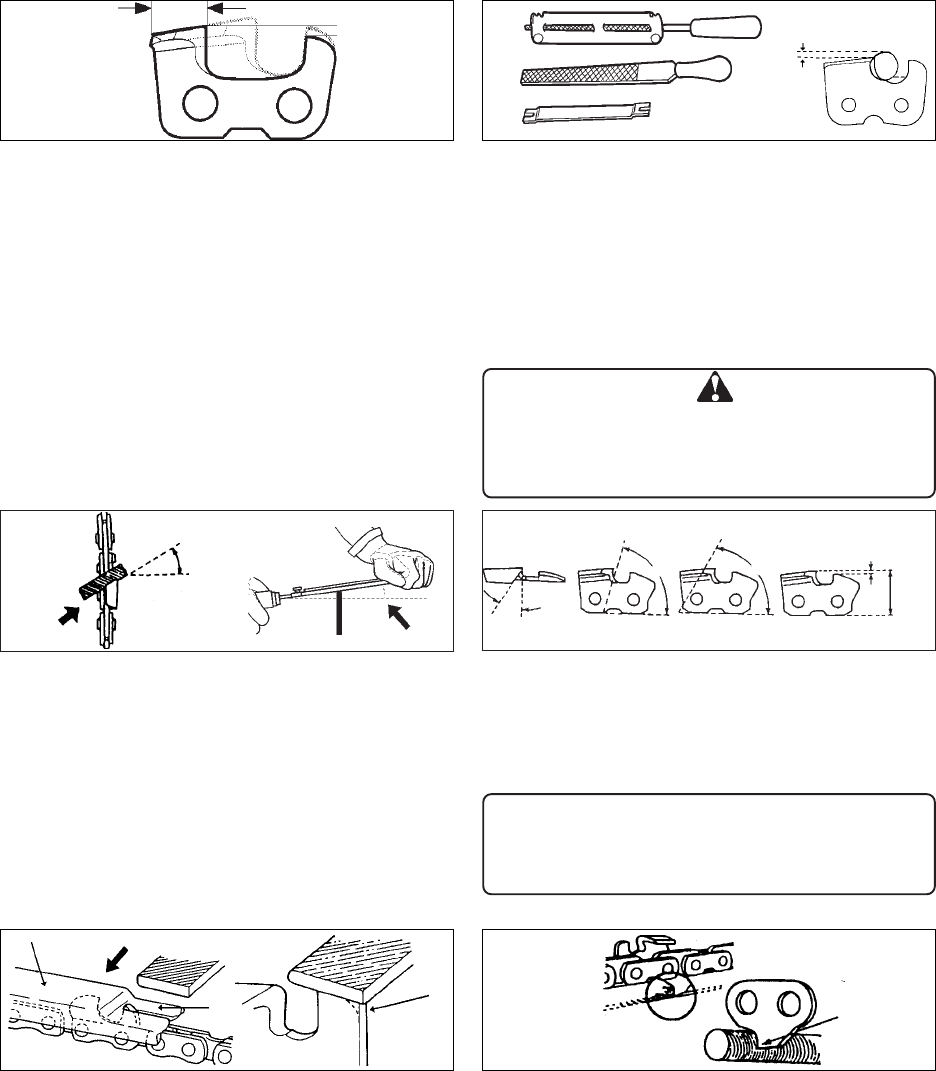

SAW CHAIN MAINTENANCE

4 mm

0.76 mm

A

B

C

1/5

WARNING DANGER

SWITCH OFF THE ENGINE BEFORE SHARPENING

THE CHAIN.

ALWAYS WEAR GLOVES WHEN WORKING ON

CHAIN.

30°

4

10°

2

3

Never operate a chain saw with a dull or damaged

chain. If the chain requires excessive pressure to cut or

produces dust instead of wood chips then inspect the

cutters for damage. When sharpening the chain the

objective will be to maintain the same angles and

profiles throughout its life as when it was new.

Inspect the chain for damage or wear every time you

refuel your chain saw.

When the length of the cutting teeth has worn down to

only 4 mm the chain must be replaced.

• Sharpening

In order to file the chain correctly you need:round file

and file holder (A), flat file (B) and a depth gauge tool

(C).

By using the correct file size (5.6 mm Round file) and a

file holder, it is easier to receive a good result.

Consult your ECHO dealer for correct sharpening tools

and sizes.

• Properly filed cutters are shown below.

A : Top plate angle 30°

B : Side plate angle 85°

C : Top plate cutting angle 60°

D : Depth gauge 0.76 mm

1. Lock the chain - push hand guard forward.

To rotate the chain - pull hand guard against front

handle.

2. Your chain will have alternative left and right hand

cutters. Always sharpen from the inside out.

3. Keep the angle lines of the file holder parallel to the

line of the chain and file the cutter back until the

damaged area (side plate and top plate) has been

removed.

4. Hold the file tipped 10° upward.

5. Sharpen the most damaged cutter first and then take

all the other cutters back to the same length.

1. The depth control determines the thickness of wood

chip produced and must be maintained correctly

throughout the chain life.

2. As the cutter length is reduced, the depth control

height is altered and must be reduced.

3. Position the depth gauge, and file off any of the depth

control which protrudes.

4. Round off the front of the depth control to allow

smooth cutting.

(PRECAUTION)

The following faults will increase the risk of kickback

considerably.

1) Top plate angle too large

2) Side plate angle too small

3) File diameter too small

4) Depth gauge too large

• Drive link serves to remove sawdust from the groove of

the guide bar. Therefore, keep the lower edge of the

drive link sharp, indicated as 5.

- When setting of the chain is finished, soak it in oil and

wash away filings completely before using.

- When the chain has been filed on the bar, supply

sufficient oil to it, and rotate the chain slowly to wash

away the filings before using again.

- If the chain saw is operated with filings clogged in the

groove, the saw chain and the guide bar will be

damaged prematurely.

- If the saw chain becomes soiled with resin for

instance, clean it with kerosene and soak it in oil.