www.desatech.com

115481-01B 7

INSTALLATION

Continued

The appliance gas inlet connection is 3/8" NPT at

the regulator, located at the rear of the appliance.

IMPORTANT: Hold appliance regulator with a

wrench to prevent movement when connecting

to inlet piping.

CAUTION: Use only new,

black iron or steel pipe. Inter-

nally-tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of

1/2" diameter or greater to allow

proper gas volume to heater. If

pipe is too small, undue loss of

volume will occur.

Installation must include an equipment shutoff

valve, union and plugged 1/8" NPT tap. Locate NPT

tap within reach for test gauge hook up. NPT tap

must be upstream from log set (see Figure 4).

IMPORTANT: Install equipment shutoff valve in an

accessible location. The equipment shutoff valve is for

turning on or shutting off the gas to the appliance.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant from

going into pipe. Excess sealant in pipe could result

in clogged heater valves.

WARNING: Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Install a sediment trap where it is within reach for

cleaning. Install in piping system between fuel

supply and heater. Locate sediment trap where

trapped matter is not likely to freeze. A sediment

trap traps moisture and contaminants. This keeps

them from going into heater controls. If sediment

trap is not installed or is installed wrong, heater

may not run properly.

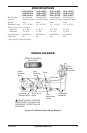

Figure 4 - Gas Connection

* Purchase the optional CSA design-certified shutoff

valve from your dealer. See Accessories, page 18.

** Minimum inlet pressure for purpose of input

adjustment.

Approved Flexible

Gas Hose (If

allowed by local

codes)

CSA Design-Certified

Equipment Shutoff Valve

with 1/8" NPT Tap*

Natural

From Gas

Meter (5" W.C.**

to 10.5" W.C.

Pressure)

Propane/LP

From External

Regulator (11"

W.C.** to 14"

W.C. Pressure)

3" Minimum

Pipe Cap Tee

Nipple Joint

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an

open flame to check for a leak.

Apply a noncorrosive leak detec-

tion fluid to all joints. Bubbles

forming show a leak. Correct all

leaks at once.

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance main

gas valve (control valve) and equipment

shutoff valve from gas supply piping system.

Pressures in excess of 1/2 psig will damage

heater regulator.

2. Cap off open end of gas pipe where equipment

shutoff valve was connected.

3. Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve

located on or near gas meter for natural gas

or using compressed air.