17

a. Set the parking brake.

b. Clean any debris from the blades. Keep

blades sharp and free of build up at all

times.

c. Sharpen blades evenly at the original 30°

angle to maintain balanced cutting blades.

Do not sharpen the underside of the

blades. Use a electric blade sharpener, a

conventional electric grinder or a hand file

to sharpen the blades.

d. Replace any blade with severe nicks or

dents that cannot be removed by filing.

e. Check the balance of the blade after

sharpening by placing it on a blade bal

-

ancer. Do not use un-balanced blades.

f. If the blade dips on one end, file stock off

of the cutting surface on that end.

Note: Blades that cannot be easily bal-

anced—REPLACE.

3. Changing the Blade Drive Belts:

a. Set the parking brake. Remove ignition key

and both spark plug caps.

b. Unscrew the wing nuts from the deck cov-

ers and remove both covers.

c. Using a 1/2" socket breaker bar or socket

rachet insert the male end into the 1/2"

opening in the lower idler arm assembly

and pull the idler arm clockwise. While

holding the idler arm back, loosen the

blade drive belt from the pulley and slide

the belt away from the pulley.

d. Remove tension of the PTO belt by moving

the belt tensioning rod. Loosen the belt

retaining bolt.

e. Pull the tensioner pulley away from the belt

and remove the PTO belt then remove the

blade drive belt.

f. Reverse the process to install the belt.

Note: When replacing belts do not over-

tighten. Adjust the idler pulley so that a ten-

pound pull with a spring scale between two

pulleys deflects the belt about 1/2".

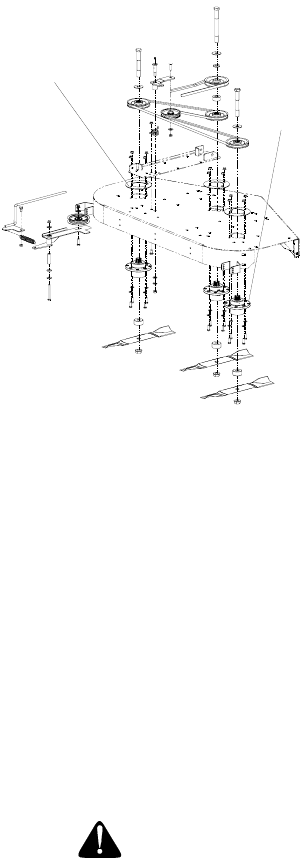

4. Changing the Spindle Assembly

a. Jack up the front of the mowing deck about

one foot and block it in that position.

b. Make sure the blade clutch is disengaged.

c. Remove the deck cover.

d. Remove the drive belts. (See 3. Changing

Blade Drive Belts.)

e. Remove the cutter blade. (See 2. Chang-

ing a Blade.)

f. Using a wrench or socket rachet remove

four hex nuts, and the four hex head cap

screws. Remove the spindle assembly.

B.Hydraulic Oil

WARNING:

Never overfill the hydraulic units. Damage can

occur if the oil level is not within the proper

operating range.

Note: When adding hydraulic oil, do so in

small quantities and recheck the oil level

before adding more. It is important that you do

not overfill the reservoir to allow for fluid

expansion.

Figure. 7

Cover

Plate

Spindle