14

5

Maintaining

Your Yard

Vacuum

WARNING

Always stop engine,

disconnect spark

plug, and ground

against engine before

cleaning, lubricating

or doing any kind of

maintenance on your

machine.

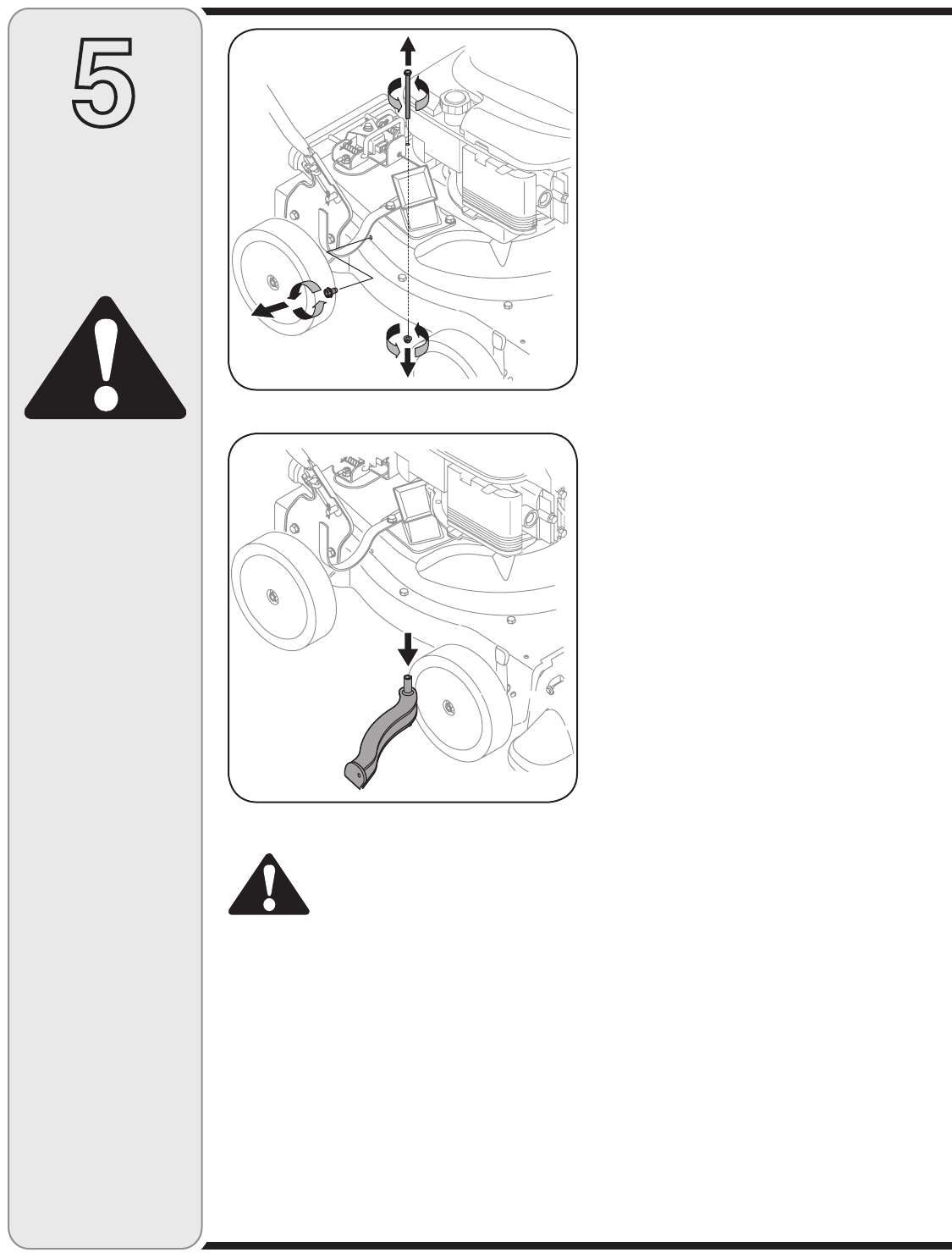

Figure 5-1

Figure 5-2

WARNING: Always stop engine,

disconnect spark plug, and ground

against engine before cleaning,

lubricating or doing any kind of

maintenance on your machine.

Lubrication

1. Wheels: Lubricate each wheel shoulder screw

(rear wheel) and pivot arm axle (front wheel) once a

season with light oil. See Figure 5-3.

2. Nozzle height adjustment levers: Lubricate the

pivot points of the nozzle height adjustment levers

once a season with light oil. Refer to Figure 7.

3. Locking Rod: Lubricate the locking rod with light oil

to ease the application of attaching on or removing

bag. Refer to Figure 6.

4. Nozzle/Hose Vac Lever: Lubricate the nozzle/hose

vac lever on top of nozzle once a season with light oil.

Refer to Figure 4-1.

5. Engine: Follow the separate engine manual packed

with your unit for lubrication instructions.

Engine Care

Refer to the Maintenance section of the Briggs & Stratton

Owner/Operator manual packed with your unit. Read and

follow instructions carefully.

1. Check engine oil level before each use as instructed

in the separate engine manual.

2. Clean air cleaner’s precleaner every 25 hours under

normal conditions. Clean every few hours under

extremely dusty conditions. To service the air cleaner,

refer to the separate engine manual.

3. The spark plug should be cleaned and the gap reset

once a season. Refer to the separate engine manual

for correct plug type and gap specifications.

Removing The Flail Screen

If the discharge area becomes clogged, remove the flail

screen and clean area as follows:

1. Stop the engine and make certain the Yard Vacuum

has come to a complete stop.

2. Disconnect and ground the spark plug wire to the

retaining post.

3. Remove the bag from the unit as instructed in the

OPERATING YOUR YARD VACUUM section to obtain

access to flail screen.

4. Remove self-tapping screw on right side of unit that

attaches to the fail screen. It may be necessary to

remove the hose bracket hanger to get access to the

hex screw. See Figure 5-1.

5. Remove hex screw on top of rear housing mounting

bracket and the flange lock nut that secures flail

screen. See Figure 5-1.

6. Remove and clean the screen by scraping or washing

with water. See Figure 5-2.

7. Reinstall the flail screen.

Sharpening Or Replacing Chipper

Blade

Because the engine on this unit has a tapered crankshaft,

a special impeller tool (part number 753-0900) is required

to remove the impeller assembly. For further assistance,

contact your local service dealer.

NOTE: When tipping the unit, empty the fuel tank and

keep spark plug side up.

1. Disconnect and ground the spark plug wire to retain-

ing post.

2. Remove hose assembly and bag assembly.