the unit runs out of gas as it is shredding or chipping,

it may be necessary to unclog the unit before it can be

restarted. Refer to "Removing the Flail Sc'een" in

SERVICE AND ADJUSTMENT section.

WARNING: EXPERIENCE INDICATES THA1 ALCO-

HOL BLENDED FUELS (CALLED GASOI-OL OR

USING ETHANOL OR METHANOL) CAN AITRACT

MOISTURE WHICH LEADS TO SEPARATION AND

FORMATION OF ACIDS DURING STORAGE.

ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL S_STEM

SHOULD BE EMPTIED OR TREATED WITH FUEL

STABILIZER BEFORE STORAGE FOR 3( DAYS

OR LONGER. USE FRESH FUEL NEXT SE!ASON.

SEE "STORAGE" SECTION FOR ADDIIlONAL

INFORMATION.

NEVER USE ENGINE OR CARBURETOR (;LEAN-

ER PRODUCTS IN THE FUEL TANK OR PERMA-

NENT DAMAGE MAY OCCUR.

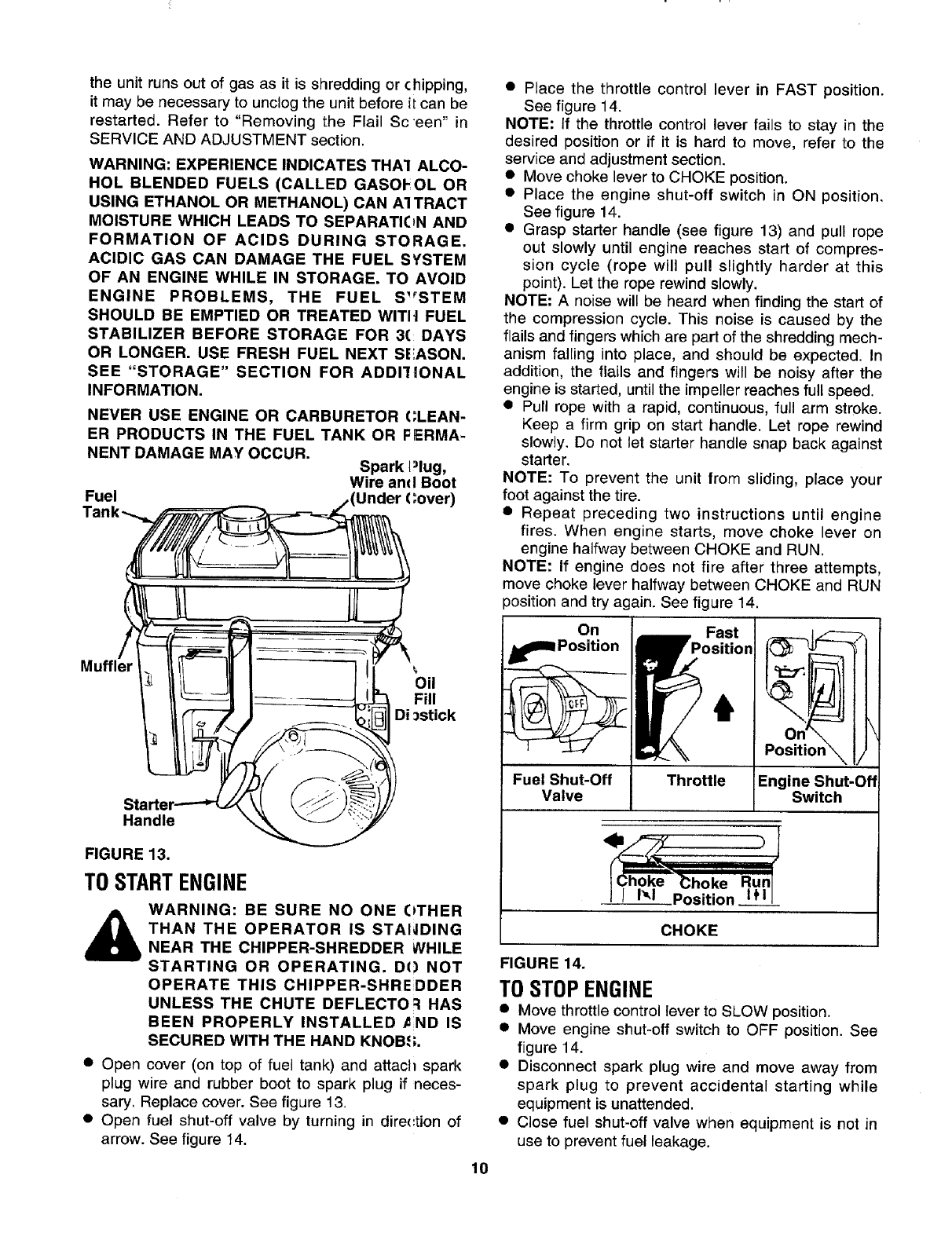

Spark I_lug,

Wire and Boot

Fuel Under (;over)

Muffler

Oil

Fill

Di _stick

Handle

FIGURE 13.

TO STARTENGINE

&

WARNING: BE SURE NO ONE OTHER

THAN THE OPERATOR IS STANDING

NEAR THE CHIPPER-SHREDDER WHILE

STARTING OR OPERATING. D() NOT

OPERATE THIS CHIPPER-SHREDDER

UNLESS THE CHUTE DEFLECTO:I HAS

BEEN PROPERLY INSTALLED ._ND IS

SECURED WITH THE HAND KNOB.€;.

• Open cover (on top of fuel tank) and attach spark

plug wire and rubber boot to spark plug if neces-

sary. Replace cover. See figure 13.

• Open fuel shut-off valve by turning in dire(:tion of

arrow. See figure 14.

10

• Place the throttle control lever in FAST position.

See figure 14.

NOTE: If the throttle control lever fails to stay in the

desired position or if it is hard to move, refer to the

service and adjustment section.

• Move choke lever to CHOKE position.

• Place the engine shut-off switch in ON position.

See figure 14.

• Grasp starter handle (see figure 13) and pull rope

out slowly until engine reaches start of compres-

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers which are part of the shredding mech-

anism falling into place, and should be expected. In

addition, the flails and fingers will be noisy after the

engine is started, until the impeller reaches full speed.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on start handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter.

NOTE: To prevent the unit from sliding, place your

foot against the tire.

• Repeat preceding two instructions until engine

fires. When engine starts, move choke lever on

engine halfway between CHOKE and RUN.

NOTE: If engine does not fire after three attempts,

move choke lever halfway between CHOKE and RUN

)osition and try a

On

Fuel Shut-Off

Valve

ain. See figure 14.

oO;,on

Throttle Engine Shut-Off

Switch

(_hoke' _hoke Run

J Ixl Position_l f I

CHOKE

FIGURE 14.

TO STOP ENGINE

• Move throttle control lever to SLOW position.

• Move engine shut-off switch to OFF position. See

figure 14.

• Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

• Close fuel shut-off valve when equipment is not in

use to prevent fuel leakage.