88

Undercarriage

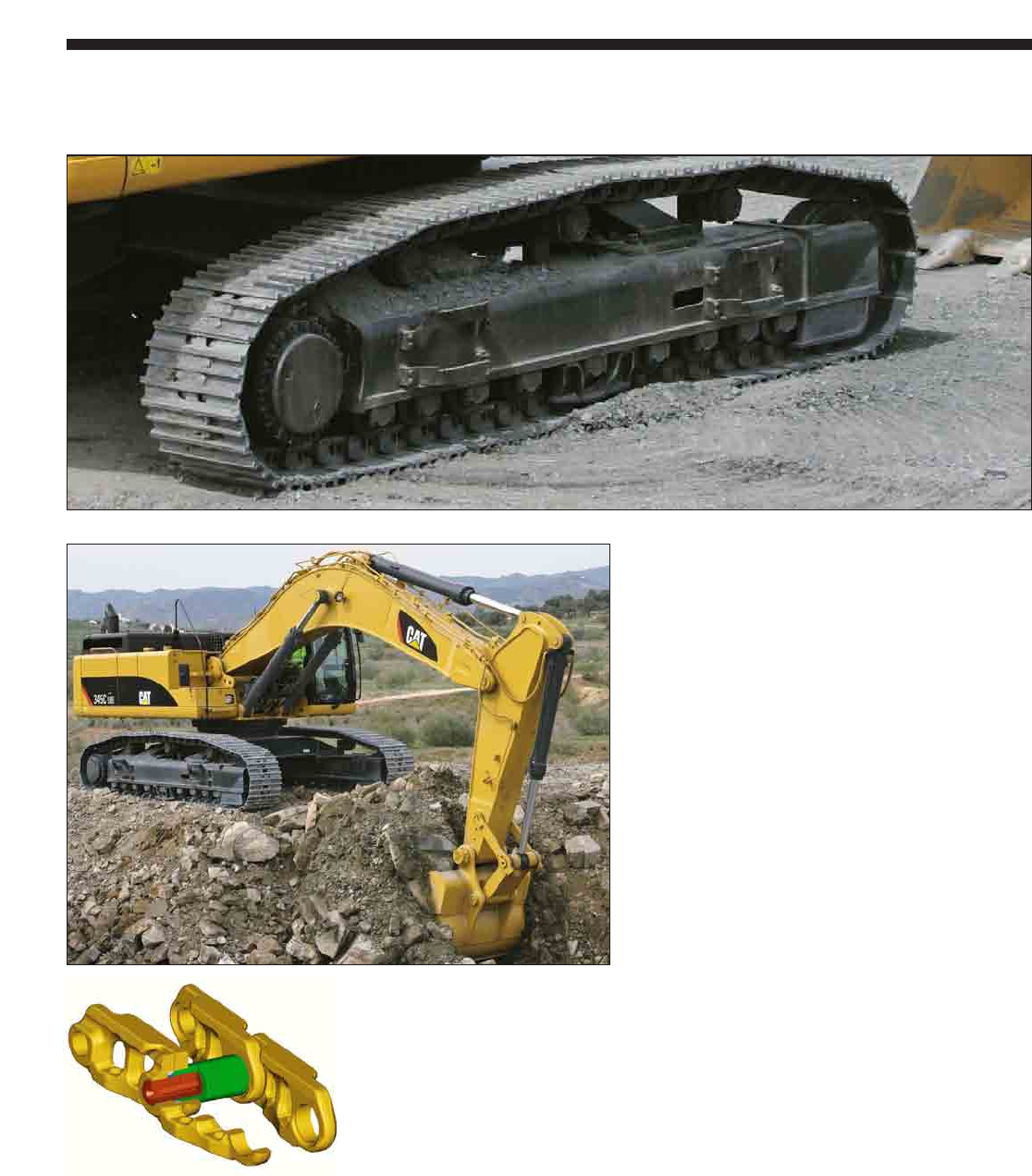

Durable undercarriage absorbs stresses and provides excellent stability.

Travel Motors. Two-speed axial piston hydraulic

motors provide the 345C L drive power and speed

selection which is automatic when the high-speed

position is selected. This enables the machine to

automatically change between computer-controlled

high and low speeds depending on drawbar-pull

requirements.

Straight-line Travel Circuit. The straight-line travel

circuit is incorporated into the hydraulic system,

which maintains low-speed, straight-line travel,

even when operating the front linkage.

An optional straight travel pedal controls both

tracks simultaneously.

Final Drive. The final drives are a new compact

design with three-stage planetary reduction.

This design results in a complete drive/brake unit

that is compact and delivers excellent performance

and reliability.

Track Guards. The idler guard and bolt-on center

guard are standard equipment. They help maintain

track alignment while traveling or working on slopes.

For applications that require additional track protection

or alignment, optional guards are available.

Extreme Service Undercarriage. Attachment includes

next size larger track roller frame and moving under-

carriage components for increased stability and extra

rugged reliability in hard-rock and severe impact

conditions.

Fixed Gauge Undercarriage. Attachment provides

a stable, durable and low maintenance platform when

working on variety of sites.

Track. The 345C L comes

standard with the new grease

lubricated track called GLT4.

The track links are assembled

and sealed with grease to

decrease internal bushing wear,

reduce travel noise and extend

service life lowering operating

costs.