RTNR60 RTNR72 RTNR80

Model No. RTN60 RTN72 RTN80 RTH60 RTH72 RTH80 RTH88

Tillage Width 60” 72” 80’ 60” 72” 80” 88”

Number of Blades 28 36 40 28 36 40 44

Type Blades C-Type C-Type C-Type C-Type C-Type C-Type C-Type

Weight 664 lbs. 726 lbs. 777 lbs. 810 lbs. 884 lbs. 924 lbs. 964 lbs.

No. of Flanges 7910 7910 11

Rotor Speed 238 RPM @ 540 RPM 213 RPM @ 540 RPM

Depth of Cut 7” Adjustable with 5-Position Skid 7” Adjustable

Power to Rotor Chain Drive (#100) Single Speed Gear Drive

SPECIFICATIONS

2-1 ATTACHING TO TRACTOR

NOTE

The RTN series tiller may be offset to either side if

so desired. Instructions for offsetting are given in

paragraph 2-3.

A. Attach tiller to tractor 3-point hitch per tractor

operator’s manual. Do not attach driveline at this

time.

NOTE

Due to the many variations in tractor/implement hitch

points and corresponding differences in distances

between tractor PTO shafts and implement input

shafts, drivelines may need to be shortened as

described in the following steps:

B. Raise and lower tiller to determine position

with shortest distance between the tractor PTO shaft

and gearbox input shaft. Shut down tractor, leaving

tiller in position of shortest distance. Securely block

tiller in position.

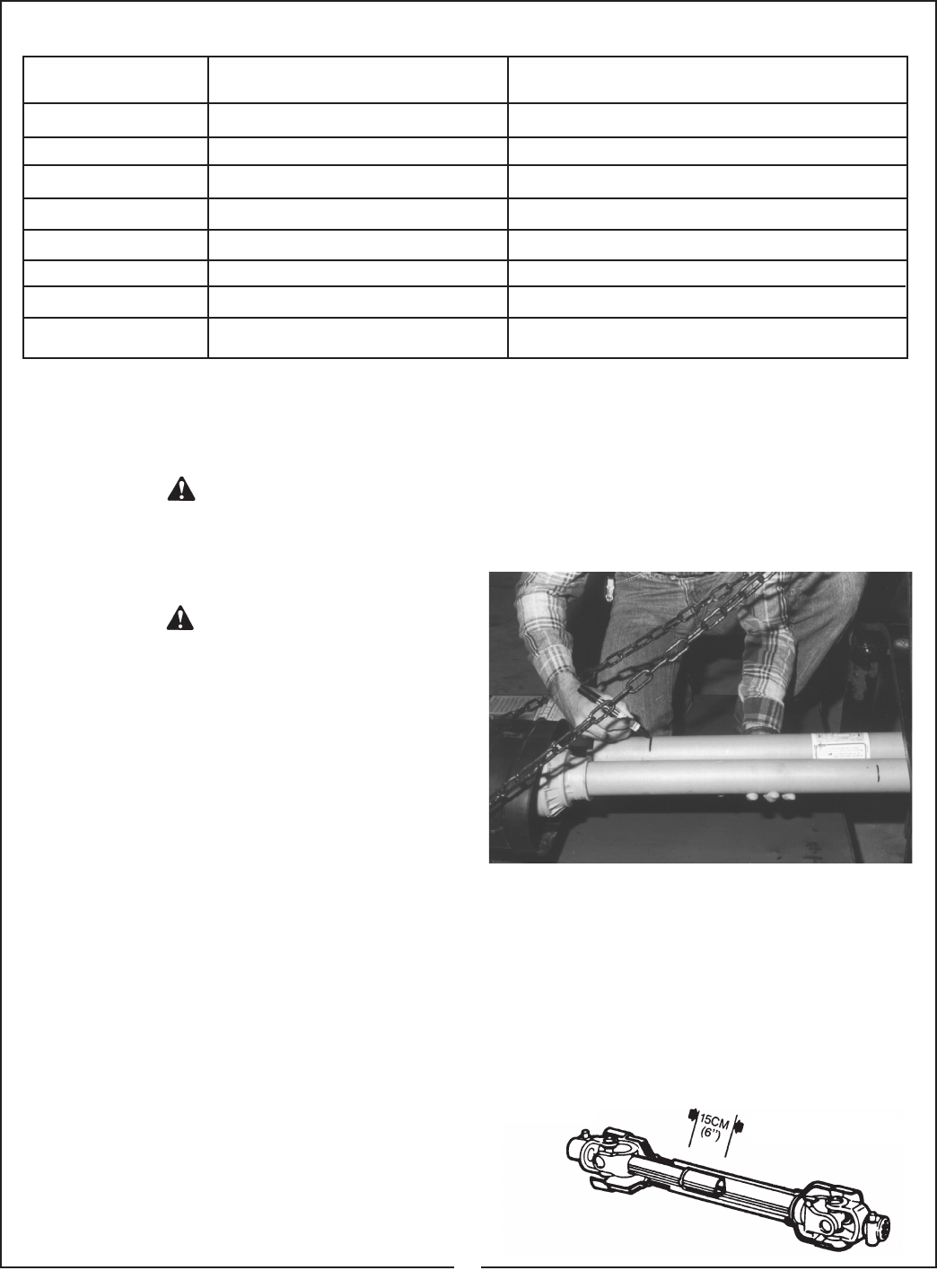

C. Pull driveline apart. Attach outer (female) sec-

tion to tractor PTO shaft. Pull on driveline section to

be sure that yoke locks into place.

D. Hold driveline sections parallel to each other

to determine if it is too long. Each section should end

WARNING

TO AVOID SERIOUS INJURY OR DEATH:

NEVER STAND BETWEEN TRACTOR

AND TILLER WHILE TRACTOR IS BEING

BACKED TO HITCH.

WARNING

TO AVOID SERIOUS INJURY OR DEATH:

ADDITIONAL TRACTOR FRONT BAL-

LAST MAY BE NEEDED FOR STABLE

OPERATION AND TRANSPORT OF THE

TILLER. SEE TRACTOR OPERATOR’S

MANUAL FOR RECOMMENDED WEIGHTS.

approximately 3 inches (76mm) short of reaching

universal joint shield on opposite section. If too long,

measure 3 inches back from universal joint shield

and mark on opposite section. (Figure 2-1). Do this

for both sections.

Figure 2-1

E. Raise and lower tiller to determine position

with greatest distance between PTO shaft and gear-

box input shaft. Shut down tractor leaving tiller in

position of greatest distance. Securely block tiller

in position.

F. Hold driveline sections parallel to each other

and check for minimum 6 inches (15cm) overlap.

(Figure 2-2) If driveline has been marked for cutting,

overlap will be the distance between two marks. If

driveline has less than minimum overlap, do not use.

Contact authorized Bush Hog dealer.

Figure 2-2

Minimum Overlap

7

SECTION II

PREPARATION FOR USE