SECTION IV

MAINTENANCE

4-1 MAINTENANCE CHECK LIST

Perform scheduled maintenance as outlined below.

Lower implement to ground, turn off tractor, and set

parking brake before doing maintenance inspections

or work. Some checks may require raising machine

off ground and supporting with blocks. All bolts

should be torqued as indicated in torque chart

unless otherwise indicated.

THE CUTTER CAN FALL FROM

HYDRAULIC SYSTEM FAILURE. TO

AVOID SERIOUS INJURY OR DEATH,

SECURELY SUPPORT CUTTER BEFORE

WORKING UNDERNEATH.

BEFORE EACH USE.

1. Check tractor tire air pressure. Refer to tractor

operator’s manual. Check mower tire pressure (if

pneumatic tires). Tire pressure should be 30 psi.

2. Check blades and spindles to be sure that

no foreign objects such as wire or steel strapping

bands are wrapped around them.

3. Check blade bolts for tightness. Tighten

blade bolts to 76 ft./lbs.

4. Inspect blades for wear. Replace if necessary

per paragraph 4-5. Use only genuine Bush Hog

replacement parts. If it is necessary to sharpen the

blades, remove the blades from the spindles before

sharpening. DO NOT sharpen blades while still

attached to mower.

5. Make certain all shields are in place and in

good condition. Repair or replace any missing or

damaged shields.

6. Inspect wheel(s) for wear, damage or foreign

objects. Repair or replace if necessary.

7. Perform BEFORE EACH USE lubrication per

paragraph 4-2.

8.During operation, listen for abnormal sounds

which might indicate loose parts, damaged bearings,

or other damage. Correct any deficiency before con-

tinuing operation.

AFTER EACH USE

1. Clean all debris from machine especially under-

side of deck, underneath belt shield and off safety

decals. Replace any missing or illegible decals.

2. Inspect cutter for worn or damaged compo-

nents. Repair or replace before next use. Any

replacement components installed during repair shall

include the components’ current safety decals speci-

fied by the manufacturer to be affixed to the compo-

nent.

3. Store cutter in a dry place.

40 HOURS

1. Check belt for proper tension. Refer to para-

graph 4-3.

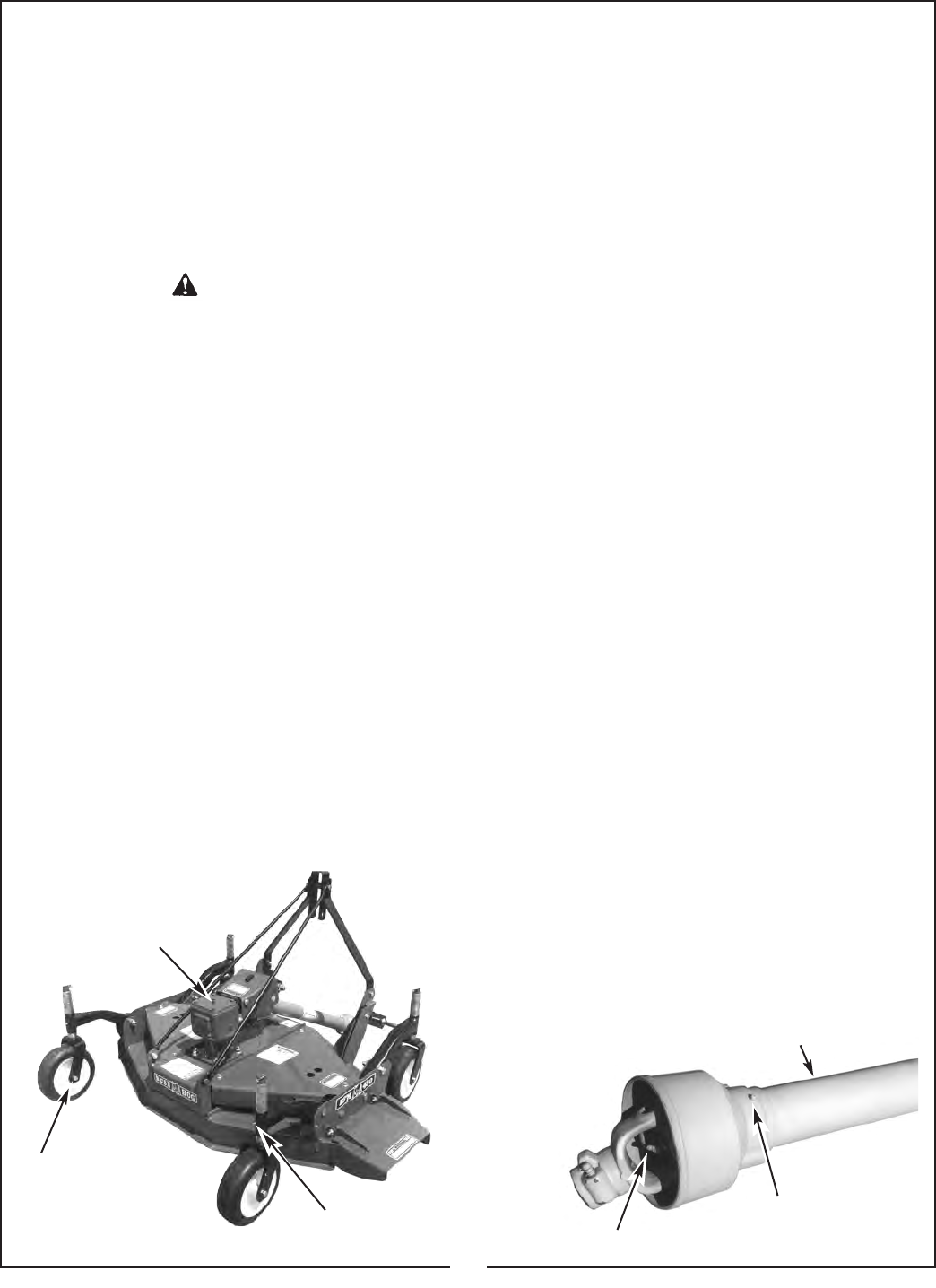

4-2 LUBRICATION (Figures 4-1A, & B)

BEFORE EACH USE

1. Driveline Universal Joints - Apply multi-purpose

grease with grease gun.

2. Driveline Guard - Apply 2-3 shots of multi-pur-

pose grease with grease gun to plastic fitting.

3. Wheels - Apply multi-purpose grease wiith

grease gun.

4. Caster Pivot - Apply multi-purpose grease with

grease gun.

40 HOURS

5. Input Gearbox - Add EP80W-90 gear oil, if nec-

essary, to bring oil level to check plug.

20 HOURS

6. Driveline - Disconnect PTO driveline, pull the

two sections apart, thoroughly clean old grease from

tubes and apply thin coat of multi-purpose grease to

outside of inner (male) section. Reassemble sec-

tions and install. Pull each section to be sure drive-

line and shields are securely connected. Make cer-

tain PTO shielding is in good condition.

NOTE

The multi-purpose grease referenced in this

secftion is an NLGI Grade 2 type grease.

Figure 4-1B

(6) 20 Hours

(2) Before Each Use

(1) Before Each Use

11

(4) Before Each Use

Figure 4-1A

(5) Before Each Use

(3) Before Each Use

WARNING