35

POWER BEYOND KITS

FOR TRACTORS WITH OPEN-CENTER HYDRAULIC SYSTEMS

General Description

A power beyond application is required to convert a

hydraulic valve so that pressurized oil can be direct-

ed to another “open center” valve. This allows the

backhoe valve and a loader valve, or other accesso-

ry, to be connected to the tractor hydraulic system

simultaneously, without the inconvenience of using a

flow diverting valve.

Since the power beyond application is only required

on “open center” hydraulic systems, oil will be con-

stantly flowing from the pump through the backhoe

and loader or other accessory valve, and then back

to the reservoir. “Open center” refers to this constant

flow through the open center of the valves.

The assembly instructions cover two conditions that

require a power beyond kit to be ordered from Bush

Hog. The first procedure shows the recommended

method of connecting a Bush Hog loader with a Bush

Hog valve to a Bush Hog backhoe. The second pro-

cedure shows the recommended method for con-

necting a Bush Hog backhoe and a competitive

loader or a non Bush Hog valve. The second is also

used to operate the backhoe and loader off the back-

hoe PTO pump kit option. In the first procedure, the

power beyond plug is included with the loader valve

when the valve is ordered. The second procedure

requires the power beyond kit for the backhoe valve

be ordered from Bush Hog as a separate item.

The hoses and fittings required in either procedure to

connect the two valves together are not supplied.

The proper fittings and hose lengths required must

be determined for each specific application. The

parts must be supplied by the customer.

Tractor Preparation

Stop tractor, lower all attachments to the ground, and

relieve pressure in all hydraulic lines by moving all

control handles back and forth or side to side several

times.

Note: The terms RIGHT and LEFT for all adapter

parts are determined from the position of the opera-

tor when seated in the operating position on the

backhoe.

FIRST PROCEDURE

ASSEMBLY OF A BUSH HOG BACKHOE

TO A BUSH HOG LOADER VALVE

IMPORTANT: Improper hydraulic hook-up can

cause serious damage to backhoe control valve or

other hydraulic components. Refer to the Bush

Hog loader Operator’s Manual during this proce-

dure.

When connecting the Bush Hog backhoe valve to a

Bush Hog front end loader valve, the input pressure

line from the tractor will be connected to the loader

valve first. The power beyond pressure line will be

connected to the input pressure port of the backhoe

valve. In order to properly plumb the system, the

loader valve will require converting to a power

beyond valve. Refer to the Operator’s Manual

received with the loader for the proper assembly of

the power beyond valve.

There have been several different valves used on the

Bush Hog loader in past years. The fittings required

to convert the Bush Hog loader valve to a power

beyond application are included in the loader valve

kit. If the fittings (or plugs) cannot be located, they

can be obtained from Bush Hog Service Parts.

Before attempting to order the plug you must first

determine the manufacturer of the loader valve

assembled to your loader. This can be determined

from the identification plate located on the valve.

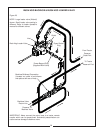

1. Install the power beyond plug received with the

loader valve into valve cavity as shown in Figure 23

(Page 36). Make sure O-rings on sleeve are posi-

tioned properly and are not pinched or damaged.

2. Install a pressure line (supplied by customer)

between the tractor pressure “out” port and the pres-

sure inlet port of the loader valve.

3. Install a pressure line (supplied by customer)

between the power beyond fitting of the loader valve

and the pressure inlet port on the backhoe bulkhead

connection as shown in Figure 23.

4. Complete assembly of “return” hoses as shown in

Figure 23. Connect tee fitting to return outlet port on the

backhoe bulkhead connector as shown. Connect return

hose from rerturn outlet port of the loader valve to the

branch port of the tee fitting. Hoses and tee supplied by

customer. Connect a second return hose from the tee

fitting directly to a port on the tractor reservoir as shown

in Figure 23.