Buhler Rollermills

Rolled or crimped grain is an excellent way to increase the nutri-

tional value of grain, making it easier for animals to digest for

faster weight gain with more weight gain per bushel.

Available in three sizes, Buhler rollermills are capable of process-

ing up to 300 bushels per hour. A manual feed gate sets the ow

into the rollermill and the adjustable tensioner determines the

thickness of nished grain. Double leaf springs ensure constant,

even roller pressure.

Machine-grooved rollers are available in steel or chrome and can

be inexpensively re-machined up to three times if damaged or

worn. An optional magnet removes nails and other metal objects

from the grain and prevents them from damaging the rollers.

An electric motor or PTO drives the Y85 and Y100. e Y180

is PTO driven and can be equipped with a transport with 15"

wheels and a 12' hydraulic discharge auger that swings a full 180

degrees.

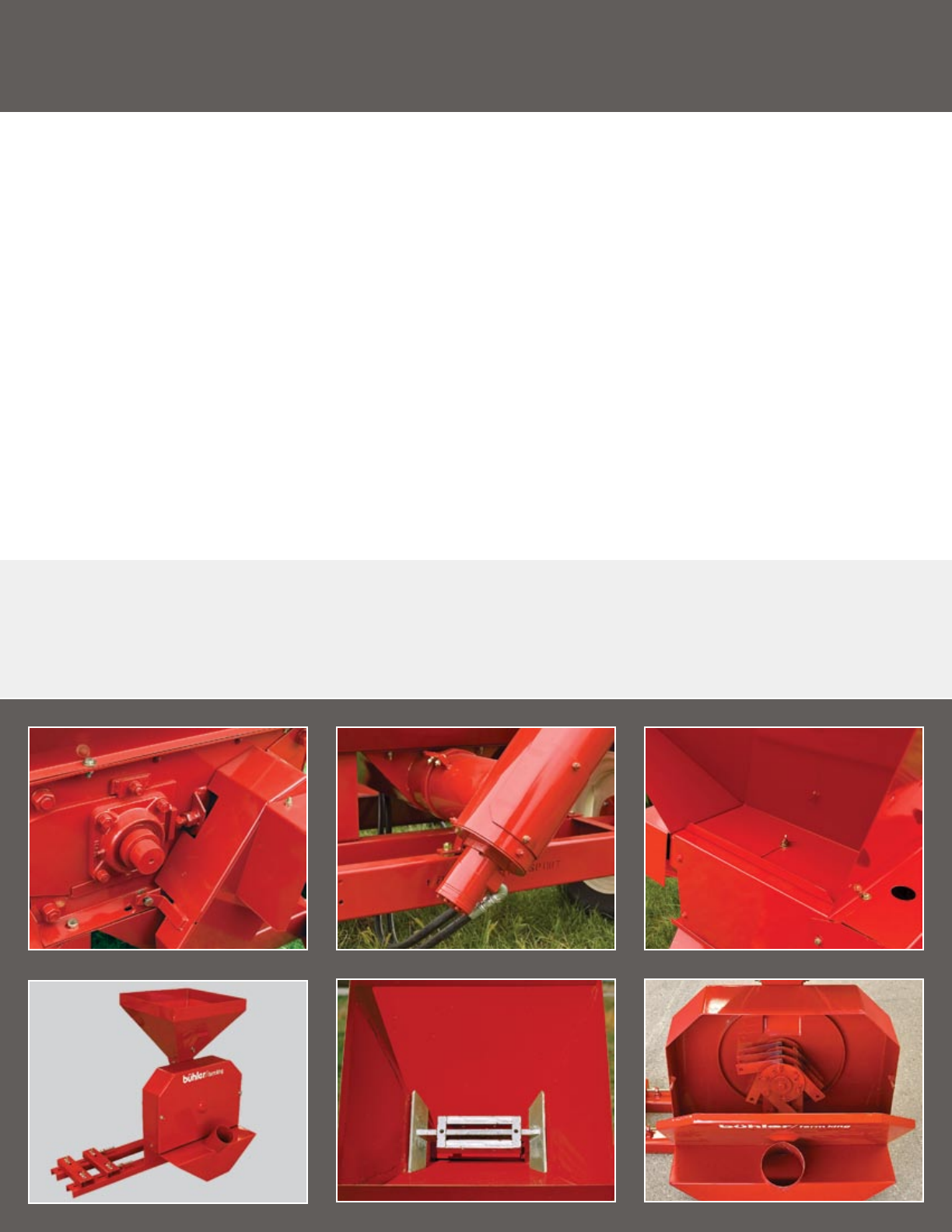

[1] High quality sealed bearings do not require maintenance.

[2] Hydraulic discharge auger is optional on the Y180.

[3] The adjustable feed gate sets the ow of grain into the machine and

is easy to adjust.

[4] The Y60 features a motor mount and stationary stand.

[5] The optional magnet removes nails and metal debris from grain.

[6] High quality carbon steel hammers are used in the Y60.

[4]

[5] [6]

[1]

[2] [3]

Buhler rollermills and hammermills are designed to maximize the nutritional value of feed.

Built with durable, heavy-gauge materials, Buhler rollermills and hammermills deliver

top-quality processed grain with minimum maintenance and low operating costs.