22 BRIGGSandSTRATTON.COM

Spark Arrester Service

Your engine is not factory-equipped with a spark arrester. In

some areas, it is illegal to operate an engine without a spark

arrester. Check local laws and regulations. A spark arrester is

available from your nearest Briggs & Stratton Authorized

Dealer.The spark arrester must be serviced every 50 hours to

keep it functioning as designed.

If the engine has been running, the muffler will be very hot.

Allow the muffler to cool before servicing spark arrester.

• Remove spark arrester screen for cleaning and

inspection.

• Replace if screen is damaged.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and freeze

pump action. Follow these procedures after every use:

1. If the detergent siphoning system was used, clean the

tube as described in Cleaning Detergent Siphoning

Tube.

2. Shut off engine, turn off water supply, point gun in a

safe direction, and squeeze trigger to relieve trapped

pressure, and let engine cool.

3. Disconnect hose from spray gun and high pressure outlet

on pump. Drain water from hose, spray gun, and nozzle

extension. Use a rag to wipe off the hose.

4. Empty pump of all pumped liquids by pulling recoil handle

about six times. This should remove most liquid in pump.

5. Store unit in a clean, dry area.

6. If storing for more than 30 days, see Long Term Storage

on next page.

Pump Maintenance

For longest lasting service, follow the instructions given in

the check list (Page 17).

IMPORTANT: Use 0.3 liter (10.15 ounces) of CAT Pump

6107 multi-viscosity oil. Oil alternatives include Mobil

DTE16, Texaco Rondo 1660-HD150, Amoco Rykon-68, Shell

Tellus T-68, and Exxon Univis-68.

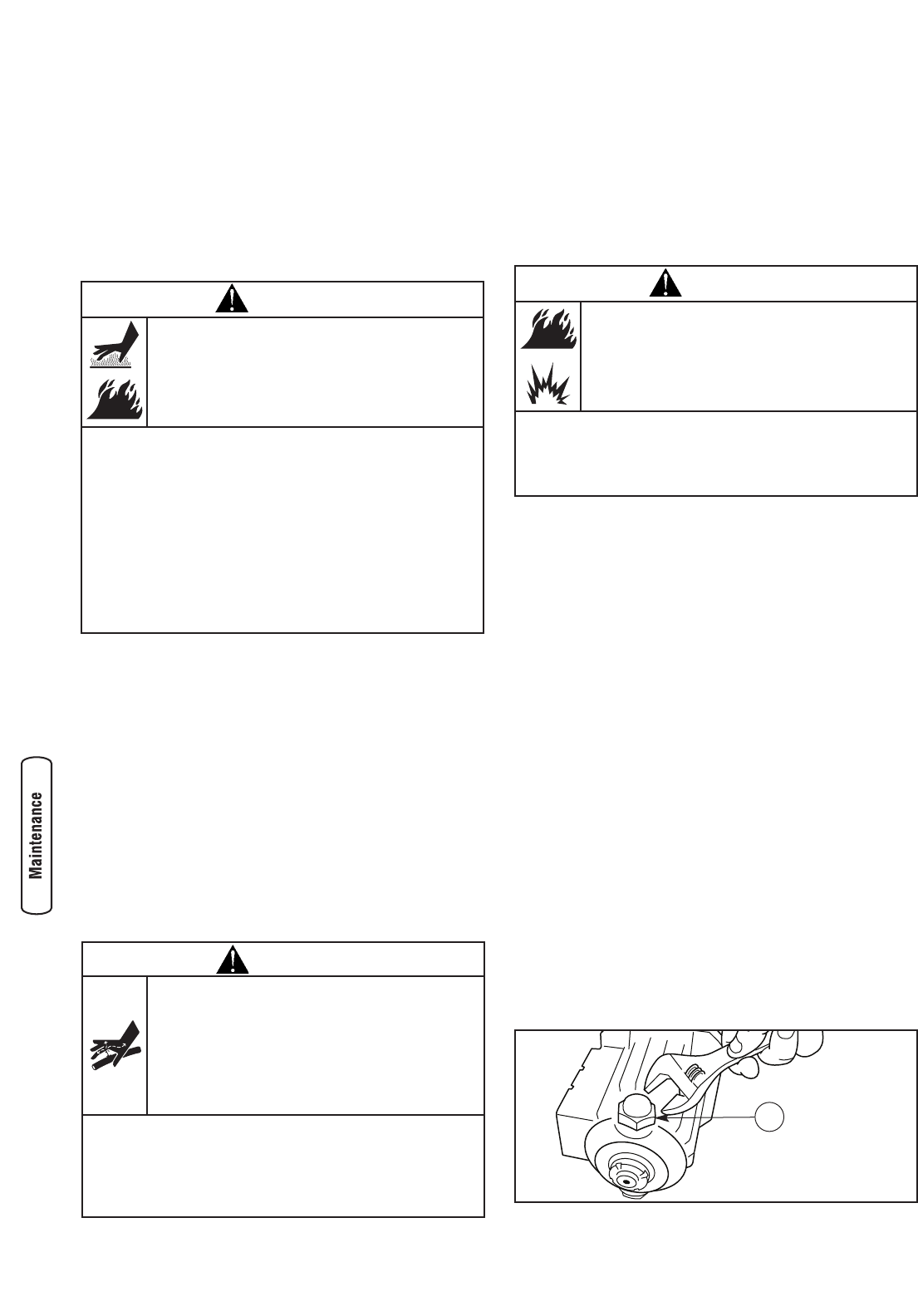

Check Pump Oil

1. Place pressure washer on a level surface.

2. While pump and oil is cold, observe oil level visible in

pump’s oil sight gauge.

3. Oil level should be visible and centered on red dot (B).

If necessary, slowly add recommended oil through

pump’s oil filler opening until oil level is centered on

red dot. DO NOT fill above red dot!

Changing Pump Oil

1. Place pressure washer on an outside level surface.

2. Start according to instructions and run pressure washer

for at least 5 minutes.

3. Turn off pressure washer and disconnect spark plug

wire from spark plug.

4. Place suitable container under oil drain hole.

5. Remove pump’s oil filler cap (A) and o-ring.

WARNING

Contact with muffler area can result in serious

burns.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of pressure

washer including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press red button and

squeeze spray gun trigger, to release high pressure, every time

you stop engine.

WARNING

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers,

or other appliances that have pilot light or other ignition source

because they can ignite fuel vapors.

A