3

Installation E19-310DC

Bradley Corporation • 215-163DCE Rev. Z; EN 06-532F 6/25/07

Installation

Supplies Required:

• (3) M10 floor anchors and bolts

• Teflon tape and pipe sealant

• Piping to 1-1/4" BSP water supply inlet on unit

• Adequate supply pipe supports

• Piping to 1-1/4" BSP drain outlet for eyewash

• Minimum 102mm (4") drain to accommodate

115 liters (30 gallons) per minute discharge for

shower waste

• OPTIONAL: sign-mounting hardware

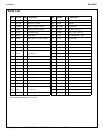

Step 1: Secure base to floor

1. Install three suitable anchors (by installer)

for M10 bolts in the floor (see Figure 1).

2. Bolt the base to the floor anchors using M10

bolts (supplied by installer).

IMPORTANT: Some teflon sealants

may cause stress cracks in the plastic

showerhead leading to failure. Use

teflon tape for sealing the showerhead.

Step 2: Assemble eyewash components

1. Assemble the remaining unit components as

shown in Figure 2 on page 4.

• Apply pipe sealant (supplied by installer) to

all male-threaded pipe joints.

• Use the rubber grip pad provided or a strap

wrench around pipes when tightening to

prevent marring. Place the grip pad on the

pipe, then put the wrench over the grip pad

and turn the pipe with the wrench.

• Bottom edge of showerhead should be

2160mm (7'-1") from floor.

Step 3: Connect water supply

IMPORTANT: Do not rely on Bradley’s

Combination Unit to support supply

piping.

1. Connect water supply piping to 1-1/4" BSP

inlet on unit (piping supplied by installer).

Provide adequate supports (supplied by

installer) for supply pipe using pipe hangers or other means.

2. Connect drain piping to 1-1/4" BSP drain outlet on unit (piping supplied by installer).

3. Hang the safety sign from the unit with the curtain hooks provided (or mount it to the wall using

sign-mounting hardware supplied by installer).

Ø 254mm

(10")

645mm

(25-3/8")

610mm

(24")

2160mm

(7'-1")

To

Floor

1676mm

(66")

To

Floor

140mm

(5-1/2")

1041mm

(41")

152mm

(6")

267mm

(10-1/2")

Ø 273mm

(10-3/4")

247mm

(9-3/4")

Ø 229mm (9") Flange

with (3) Ø 10mm (3/8")

Holes on Ø 203mm (8")

Bolt Circle

133mm

(5-1/4")

Use Teflon

Tape Only

229mm

(9")

Figure 1

NOTE: All dimensions assume standard thread

engagement. Variations in manufacturing allow

for +/- 1/8" (3mm) per threaded joint. To find

the tolerance of a dimension, add the number

of thread joints in between a dimension and

multiply it by 1/8" (3mm).