15

MAINTENANCE AND REPAIR INSTRUCTIONS

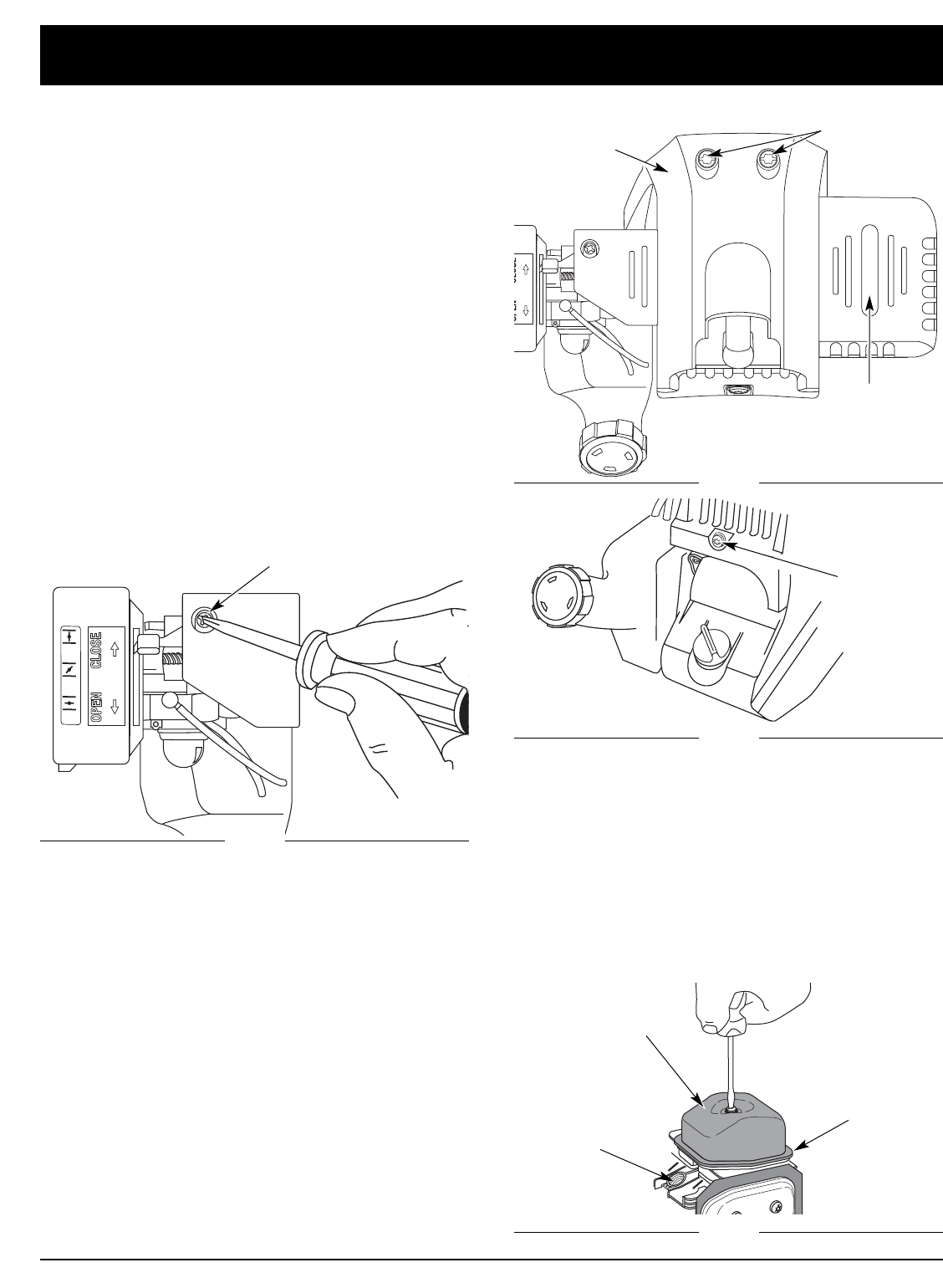

3. Disconnect the spark plug wire.

4. Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by turning it

counterclockwise with a 5/8” socket.

5. Remove the engine cover.

NOTE: To ease engine cover removal, pull the starter

rope out a little to give some slack.

6. Clean dirt from around the rocker arm cover.

Remove the screw holding the rocker arm cover with

a large flat blade screwdriver or Torx T-25 bit

(Fig. 27). Remove the rocker arm cover and gasket.

Rocker Arm Cover

Fig. 27

Spark Plug Hole

Gasket

Remove

Screws

Engine Cover

Fig. 25

Muffler

ROCKER ARM CLEARANCE

The rocker arm clearance may need adjustment if your

unit suffers a loss of performance power or has trouble

starting. Adjusting the rocker arm clearance requires

disassembly of the engine. If you feel unsure or

unqualified to perform this, take the unit to a Sears or

other qualified service dealer.

NOTE: Inspect the valve to rocker arm clearance with a

feeler gauge after the first 10 hours of operation

and then every 25 hours of operation thereafter.

• The engine must be cold when checking or adjusting

the valve clearance.

• This task should be performed inside, in a clean,

dust free area.

To adjust the rocker arm clearance:

1. Remove the two (2) screws on top of the engine cover

with a Flat-head or T-25 Torx screwdriver (Fig. 25).

2. Remove the screw behind the engine cover (Fig. 26).

Top View Of The Engine

Screw

Fig. 26

1

23

Idle Adjustment Screw

Checking the fuel, cleaning the air filter, and adjusting

the idle speed should solve most engine problems. If not

and all of the following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by a Troy-Bilt or other

qualified service dealer.

Fig. 22

NOTE: Ensure the tines are not in contact with the

ground when adjusting the idle.

2. Release the throttle trigger and let the engine idle. If the

engine stops, insert a small phillips or flat blade

screwdriver into the hole in the air filter/muffler cover

(Fig. 22). Turn the idle speed screw in, clockwise, 1/8 of

a turn at a time (as needed) until the engine idles

smoothly.

NOTE: The tines should not rotate when the engine idles.

3. If the tines rotate when the engine idles, turn the idle

speed screw counterclockwise 1/8 of a turn at a time

(as needed), to reduce idle speed.