11

4

WARNING

Never run the engine

indoors or in a poorly

ventilated area. Engine

exhaust contains

carbon monoxide, an

odorless and deadly

gas.

This Operators Manual covers a range of product

specifications for various models. Characteristics and fea-

tures discussed and/or illustrated in this manual may not

be applicable to all models. MTD LLC reserves the right

to change product specifications, designs and equipment

without notice and without incurring obligation.

Starting Engine

WARNING: Never run the engine

indoors or in a poorly ventilated area.

Engine exhaust contains carbon monox-

ide, an odorless and deadly gas.

IMPORTANT: Because this manual covers several

different model units, different starting instructions may

apply to your particular engine. Some engines may have

a fuel petcock, some may not. Some engines may have

On/Off switches, other may not. Some units will utilize a

choke system, while others will require priming. These

factors depend on what make and model engine comes

with your particular unit. For these reasons, please refer

to the engine operator’s manual for the correct starting

procedure.

1. Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug is fastened

securely over the metal tip on the spark plug.

2. Engines with choke lever:

Move choke lever on engine to CHOKE position. (A

warm engine may not require choking).

Engines with primer:

Prime engine as instructed in separate engine manual.

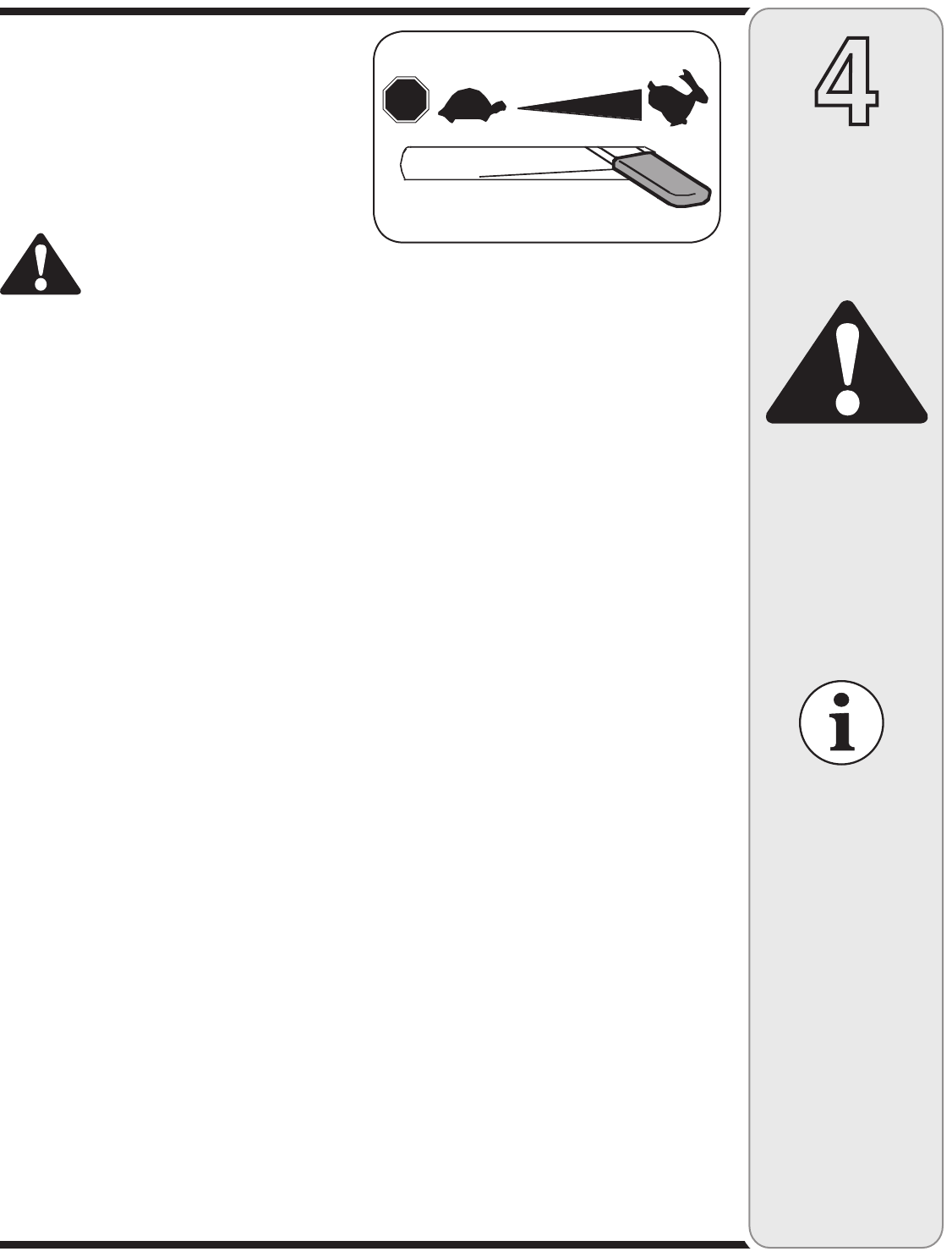

3. The throttle control lever is located on the engine.

Move engine throttle control lever to FAST or START

position. See Figure 4-2.

4. Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope will

pull slightly harder at this point).

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the flails

and fingers, which are part of the shredding mechanism,

and it should be expected until the impeller reaches full

speed.

5. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly.

6. Repeat the previous steps until engine fires. When

engine starts, move choke control (if equipped)

gradually to RUN position.

Stopping Engine

1. Move throttle control lever to STOP or OFF position.

2. Disconnect spark plug wire from spark plug and

ground against the engine.

NOTE: See your engine manual packed with your unit

for more detailed instructions.

Using The Chipper Shredder

Yard waste such as leaves and pine needles can be

raked up through the hopper assembly for shredding.

After material has been shredded by the flail blades

on the impeller assembly, it will be discharged out of

opening or into catcher bag. Do not attempt to shred

or chip any material other than vegetation found in a

normal yard (i.e. branches, leaves, twigs, etc.) Avoid

fibrous plants such as tomato vines until they are

thoroughly dried out. Twigs and small branches up to 3”

(2” for Model Series 450) in diameter can be fed into

the chipper chute.

Lowering The Hopper Assembly

1. With one hand grasp the handle at the top of the

hopper assembly and lift slightly.

2. With the other hand pull out on the release rod

and lower the hopper assembly to the ground. See

Figure 4-1.

To Empty Bag

1. Un-clip drawstring and loosen bag from chute

deflector opening.

2. Empty bag and reattach to the discharge chute

opening. Pull on the drawstring until the bag is tight

around the chute opening and clip the drawstring

tight against the chute deflector.

IMPORTANT: The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

SECTION 5: MAINTAINING YOUR CHIPPER SHRED-

DER. For best performance, it is also important to keep

the chipper blade sharp.

Operating

Your Chipper

Shredder

NOTE: A noise will be

heard when finding the start

of the compression cycle.

This noise is caused by

the flails and fingers, which

are part of the shredding

mechanism, and it should

be expected until the impel-

ler reaches full speed.

Figure 4-2

STOP