Part No 891204 Form No F060911E

9

KVSP/TKVSP Owner’s Manual

BELT TENSION ADJUSTMENT

DO NOT ADJUST WHILE THE MACHINE IS RUNNING!

1. Wait for engine to cool and disconnect spark plug.

2. Remove the transmission cover

3. Using two ½” wrenches loosen the two nuts on the cable that connects to the idler arm.

4. The setting of the tension on the belt is controlled by the distance on the threads of the cable. To loosen

tension, move the position towards the end of the threads and in the opposite direction to tighten.

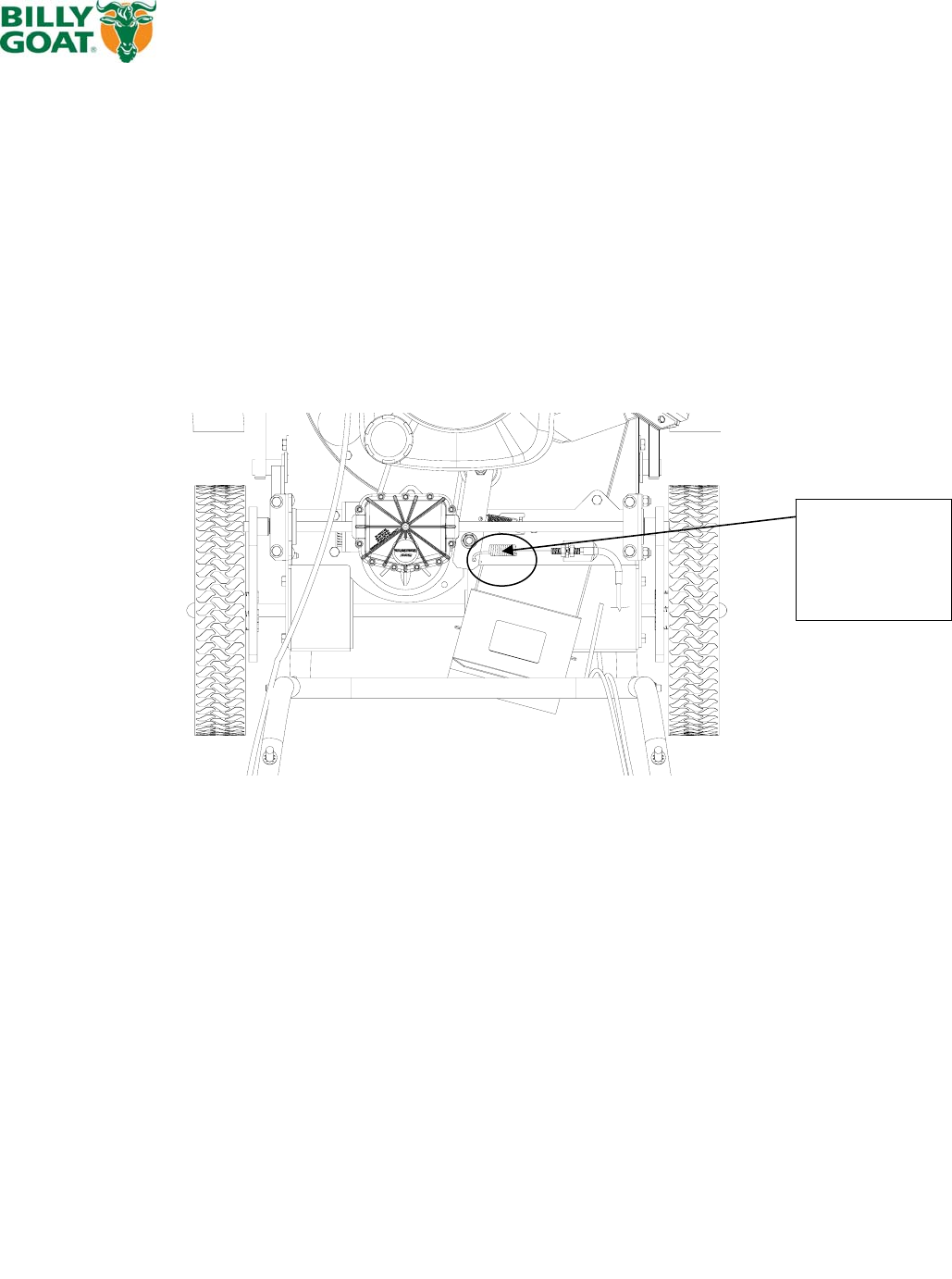

5. Check the travel of the idler arm by engaging the bail, which the drive should start to engage when the bail

is 2 ½ inches away from the handle. The spring, at a relaxed state should be 1.5 inches long on the coil, and

when the bail is in contact with the handle it should be 1.75 inches long. If the belt is too tight it can cause

premature failure and if it is too loose it can come off of the pulley.

6. When satisfied with the position, place the transmission cover back into place and secure. Then run the

machine to make sure the transmission is engaging properly. If the drive will not engage or will not disengage

repeat the previous steps.

BELT REPLACEMENT

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove bag, quick release and upper handle. Do not kink, stretch, or break control cables, control

housings, or end fittings while removing handles.

4. Remove the transmission cover, idler pulley, transmission and the belt from the transmission.

5. Remove the transmission plate and the housing top plate by removing bolts around outside of housing.

6. Leaving engine fastened to top plate, turn it upside down so the impeller is on top.

7. Remove impeller bolt and lock washer.

8. Lift impeller upward. If impeller slides freely, proceed to (step 10).

9. If the impeller does not loosen, obtain a 3/4-16x3” (Billy Goat part #440192) or longer bolt. Thread bolt by

hand into nut until bolt rests against the shaft. Tighten the bolt slowly, which will pull the impeller away from the

shaft, remove impeller from shaft. Using a penetrating oil can help loosen a stuck impeller.

10. Place the new belt on the shaft.

11. Using a new impeller bolt and lockwasher, reinstall new impeller in reverse order.

12. Tighten impeller bolt. Torque impeller bolt to 33-40 Ft. Lbs. (44-54 N.m) (see item 45 on page 15).

13. Make sure the belt is in the groove on the impeller and feed it through the hole in the top plate.

14. Reinstall engine onto housing in reverse order of removal make sure the belt is inside the two fingers on

the belt plate and that the belt is on the transmission pulley before securing the transmission.

15. Gas and oil.

16. Reconnect s

p

ark

p

lu

g

wire.

Spring length

1.5”- resting

1.75”- bail at

handle