Part No 520187 Form No F071406A

11

FM Owner’s Manual

CUTTING OPERATION

CAUTION: Shut off the blades when crossing gravel drives, walks or roads

and under all conditions where thrown objects might be a hazard.

CLEARING A CLOGGED CUTTING DECK: Turn engine off and wait for

blade to stop completely. Disconnect spark plug wire.

Wearing durable gloves, remove clog. Danger, the clog may contain

sharp materials. Reconnect spark plug wire.

CAUTION: Use extreme care when operating the blades. Inspect the work

area for foreign objects that could cause damage to the unit or injure the

operator if struck by the blade. Never operate the blades with bystanders in the

work area.

GENERAL OPERATION: To engage the blades, depress the operator’s left

hand control lever against operator’s handle. The blade is disengaged by

releasing this lever. (See Fig. 1.1) To engage the wheel drive press down on

the brake lever, lift the operator’s right hand control lever against operator’s

handle. The drive is disengaged by releasing this lever.(See Fig. 1.2) Ground

speed can be varied by shifting gears as described on page 12. To begin

cutting, engage the blade lever, allow the blade to spin up to speed, and

engage the wheel drive to begin moving forward into the material to be cut.

NOTE: Do not engage blades during transport between work sites. The blade

should remain disengaged at all times when work is not being performed.

The best performance is achieved when cutting in dry conditions. If the deck

becomes choked with grass or debris during operation, back unit off of debris

allowing machine to clear itself and continue cutting, or shut the unit off and

clear the clog by hand (See above). A drop in engine RPM or a noticeable

change in engine sound is usually a good indicator of a clogged discharge or

other interference.

Under most conditions cutting should be done in second or third gear. Fourth

gear should be reserved for conditions where grass is thinned out or not as tall.

The quality of the cut produced is directly related to the unit's ground speed

during cutting. If the quality of the cut is not satisfactory (i.e. material left

standing) you should shift into a lower gear during cutting. For improved control

in confined areas, this machine can be pushed forward or backward by

releasing the drive lever and shifting to neutral located at the bottom of the

operator's right-hand handle while depressing the brake release

lever.

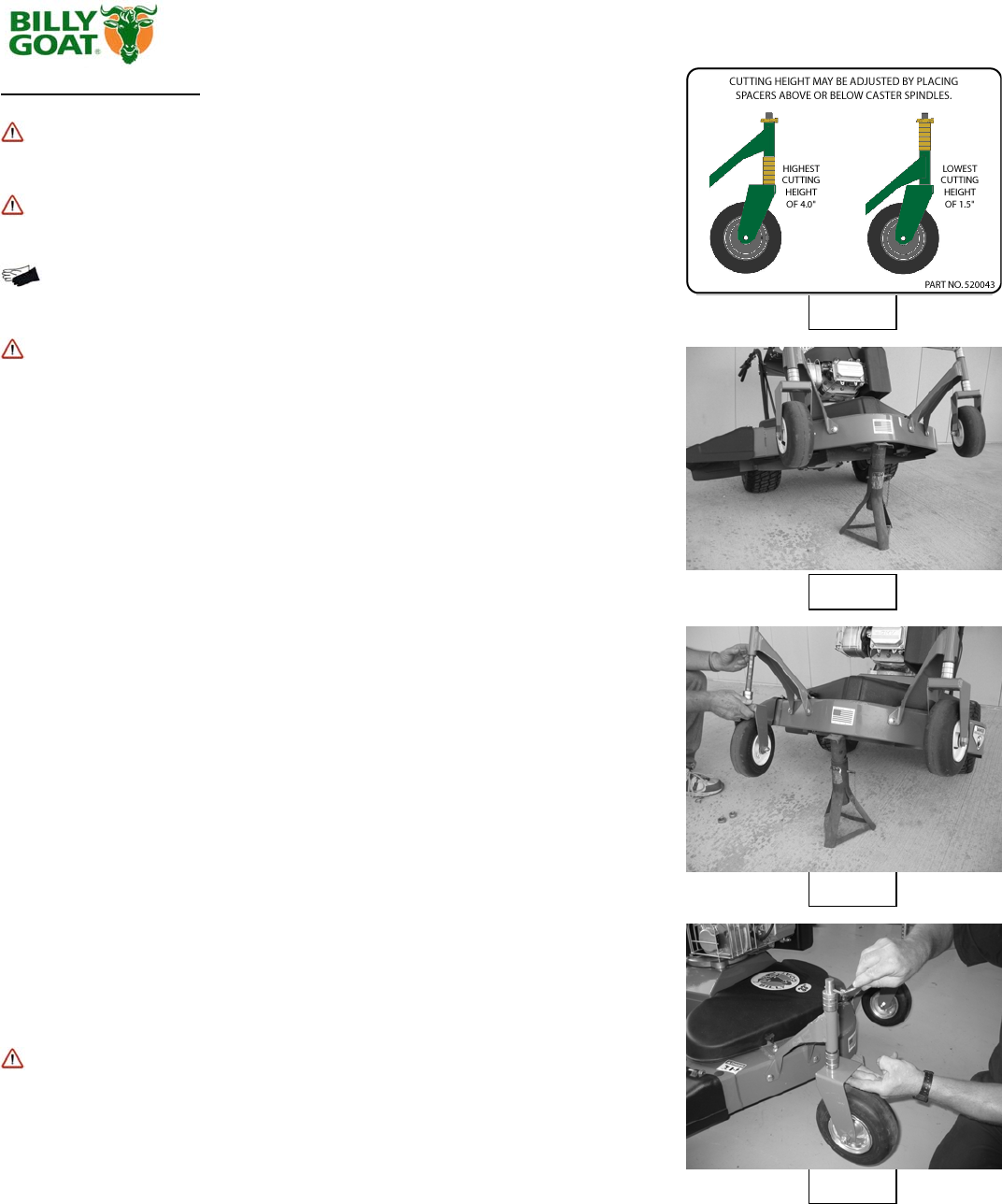

Fig. 16-2

Fig. 16-1

Fig. 16-3

Fig. 16-4

CUTTING HEIGHT ADJUSTMENT

CAUTION: DO NOT make cutting height adjustment when engine is running.

Cutting height can be adjusted from 1.5" to 4" by placing spacers above or below

caster spindles. For easiest adjustment change the height on one side at a time.

To change cutting height, tilt the unit back, remove lynch pin, remove all spacers

then set if off to the side, remove caster rig, add or subtract spacers, reinstall

caster rig, place remainder of spacers if any, then reinsert lynch pin (see figure

16-1 through 16-4). Repeat this step on other side.

NOTE: Be sure that the spacers are even on both casters. Running the deck out

of level will result in poor cut quality and increased belt wear.