Part No 440271 Form No F070809A

13

FORCE BLOWER Self-propelled Owner’s Manual

DRIVE CHAIN REPLACEM

ENT

1. Wait for engine to cool and disconnect spark plug.

2. Place a block of wood, or another object that will support and

steady the unit under the axle on the side of the machine you will

be working on.

3. Remove the two screws (item 103) holding the chain guard

(item 104) and then remove the chain guard.

4. Loosen the two nuts (item 98) holding the bearing (item 97).

5. Remove the retaining ring holding the wheel on and then slide

the wheel off.

6. Replace the chain (item 105). Remove the old chain by walking

it off the sprockets.

7. Position the bearing so that it applies the proper tension to the

chain and tighten the nuts holding the bearing Note: DO NOT

over tighten the chain, as this will cause premature failure.

Likewise if the chain is too loose it will come off when the drive is

engaged.

8. Reassemble the machine using steps 1-4 in reverse order.

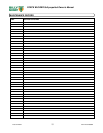

BELT TENSION ADJUSTM

ENT

DO NOT ADJUST WHILE THE MACHINE IS RUNNING!

1. Wait for engine to cool and disconnect spark plug.

2. Loosen the nut (item 92) on the Idler pulley (item 93) but do not remove it. This should allow the pulley to

slide left or right. Once the pulley is at the proper distance to apply tension to the belt tighten the nut. Note: Do

not place too much tension on the belt, as it will cause premature failure.

3. Reattach the spark plug.

BELT REPLA

CEMENT

1. Wait for engine to cool and disconnect spark plug.

2.Follow the Impeller removal steps (2-5 on page 12).

3. Remove the four bolts (item 8) holding the back plate (item 4) to the

back housing (item 6).

4. Loosen the nut on the idler pulley and slide it to the right to relieve

tension on the belt.

5. Slip the belt (item 86) off the engine pulley and the transmission.

6 Replace the belt with a new one and slide the Idler pulley to put

proper tension on the belt. Note: Do not place too much tension

on the

belt, as it will cause premature failure.

7. Reassemble the machine in reverse order. Note: You will need to

replace the Impeller bolt and torque to the proper specifications see

page 16, DO NOT use the old one.

8. Reconnect spark plug wire.

CLUTCH CABLE ADJUSTM

ENT

1. With the machine off, loosen the two nuts on the end of the clutch cable (item 111) going in to the transmission.

2. By moving the position up or down on the threads it will change the tension on the clutch lever (item 113). Note: Do not

position it too high on the threads as this could cause the drive not to engage. Likewise, if it is placed too low the drive may

stay permanently engaged. The optimum setting is to remove any slack in the clutch cable when disengaged. The travel of

the clutch control will apply the correct spring force on the cone clutc

h. Once the desired position is in place tighten the nuts

securely.

3. Start the machine and check the operation. If the drive cable is not engaging properly, shut the machine off and

reposition the nuts on the cable to tighten the drive cable.

Idler Pulley

Loosen these

nuts