Part No. 500264 Form No. F051903A

Page 11 of 12

MAINTENANCE continued

17

Transaxle

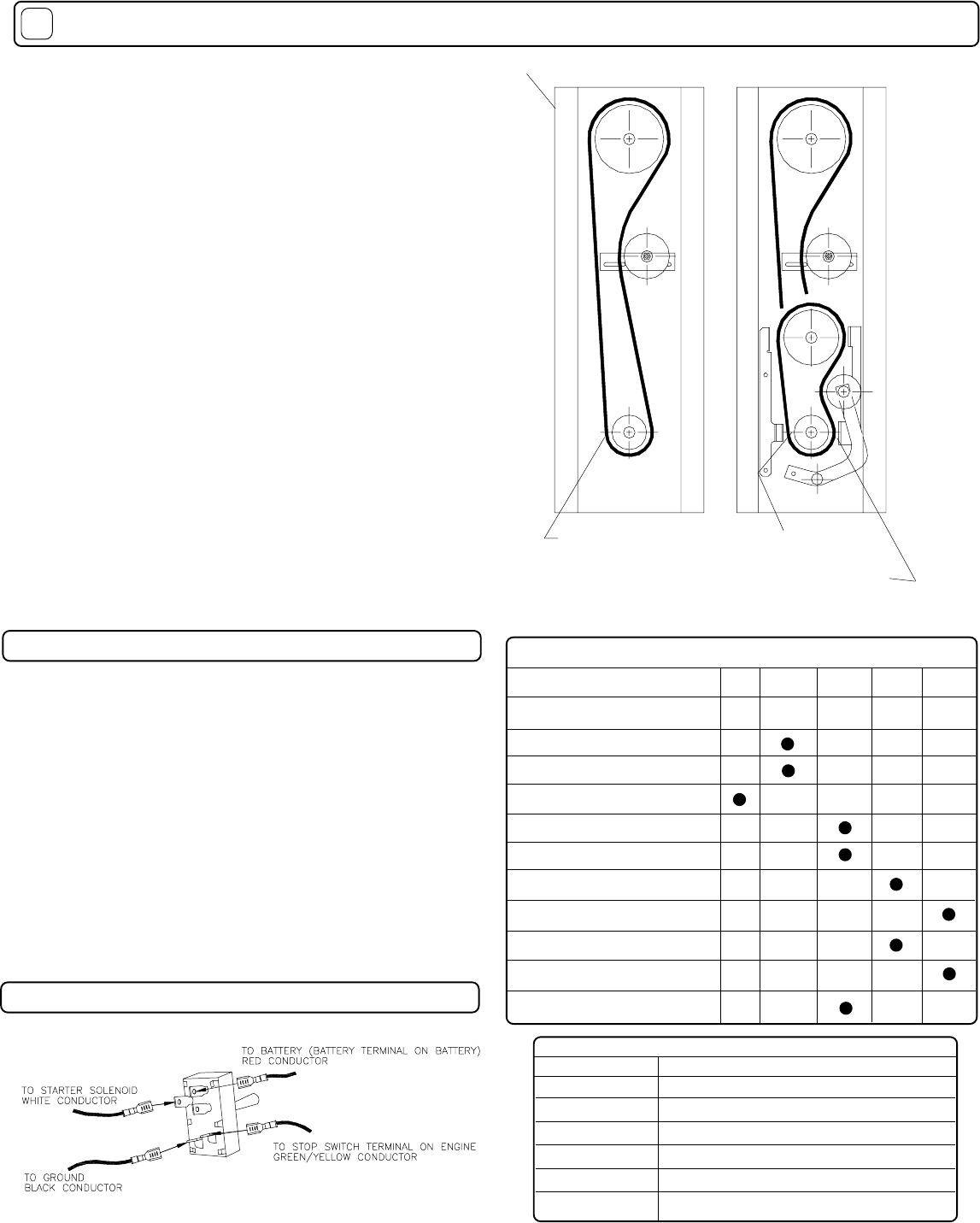

Drive Belt

Blade Drive Belt

Fig. 3

Belt in top groove

of engine pulley

Belt in bottom groove

of engine pulley

Engine (See Engine Manual)

Check for excessive vibration

Inspect for loose parts

Maintenance Operation

Follow these hourly

maintenance intervals.

Maintenance Schedule

Inspect for worn or damaged parts

Every

Use

Every 50

hrs

Every 5 hrs

or (Daily)

Every 25

hrs

Sharpen Blade

Inspect belts for wear

Replace blade and traction belts

Check blade clutch cable tension

MAINTENANCE HISTORY

Service Performed

Date of Service

Every

100-150 hrs

1. Disconnect spark plug wire.

2. Remove the two screws holding the engine base door (item 7),

and remove the door.

3. Examine the condition of the belt and note the position of the idler

assembly and the amount of tension on the blade belt.

3. Loosen the two nuts (Item 117) on top of the engine base, holding

the idler arm assembly (Item 26) in place .

4. Reset tension on belt by reaching in through top of engine base

with a long screwdriver or other pry bar and pushing the idler pulley

over against the belt to increase tension. While holding the belt

under tension tighten the two screws that hold the idler arm in place.

5. Replace engine base door and verify blade belt tension setting by

operating the unit in the conditions that caused it to slip

originally.NOTE: If belt continues to slip it may be worn out and

require replacement before proper operation can resume.

BLADE DRIVE BELT TENSION ADJUSTMENT

6. With the guides loose slip the blade drive belt(29) out of the groove

on the drive pulley and down past the pulley. Note: It is necessary to

remove the transaxle drive belt(10) from its groove to allow removal of

the blade drive belt.

7. Pull the belt back through the hole in the top of the engine base

and remove it from the machine. NOTE: Removal of the belt from the

blade drive pulley requires some force to walk the belt past the front

portion of the pulley.

8. Install new belt into groove on blade drive pulley. Push remaining

length of belt back through engine base toward clutch/brake drive

pulley.

9. Reach through from rear of machine and pull new belt through and

install it in the groove on the clutch/brake drive pulley. NOTE: Make

sure the blade belt is properly seated in the clutch/brake drive

pulley(Item 23) and not resting in the gap between the clutch/brake

pulley(23) and the transaxle drive pulley(46)

10. Tighten four screws to secure belt guides (item 149 & 150) in

place. NOTE: Be sure belt is correctly routed when replacing. (See

Fig. 3)

11. Set tension on belt by reaching in through top of engine base with

a long screwdriver or other pry bar and pushing the idler pulley over

against the belt to increase tension. While holding the belt under

tension tighten the two screws (107) that hold the idler arm in place.

Note: Proper belt tension can be verified by checking the tight side

(non-idler side)belt deflection. The belt should deflect 3/16”-1/4” with

force applied perpendicular to the belt after tensioning.

12. Replace engine base door (item 7) and tighten screws to hold it in

place

13. Reconnect spark plug.

Inspect battery for damage or leak

Check battery terminal for corrosion

STARTER SWITCH WIRING

Lubricate throttle control cable and

linkage.