Receiving & Installation 3-5MN2403

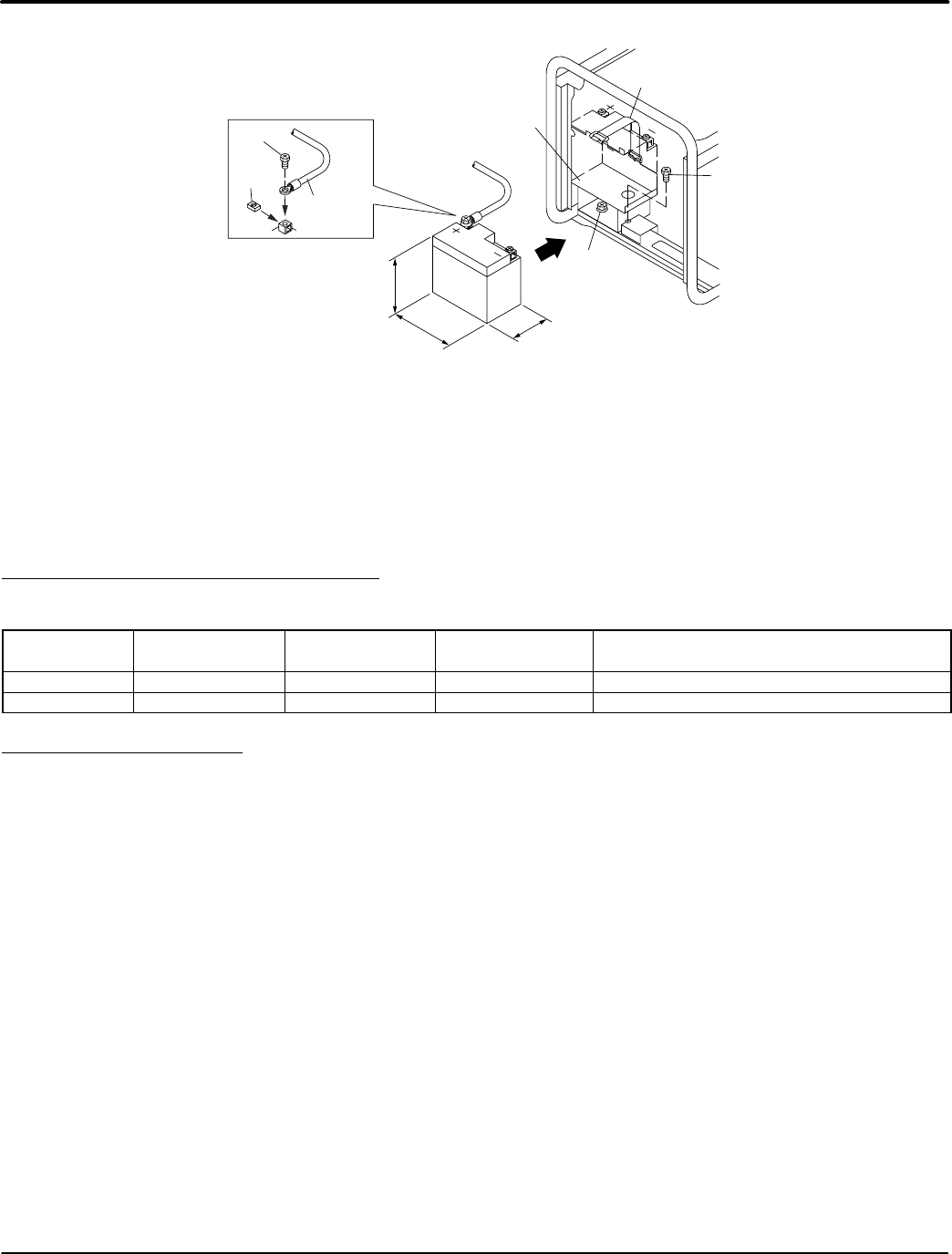

Figure 3-3 Battery Installation

Battery Base

Battery Band

Maximum Depth:

PC32Ri = 2.8 in (71mm)

PC43Ri = 3.2 in (82mm)

Maximum Height:

PC32Ri = 5.2 in (131mm)

PC43Ri = 6.4 in (162mm)

Maximum Width:

PC32Ri = 4.5 in (114mm)

PC43Ri = 5.4 in (136mm)

Red Cable

Flange

Bolt

Bolt

Nut

Flange

Bolt

5. Secure the battery in position using the Battery Band shown in Figure 3-3.

6. Do not lay tools or metal parts on top of batteries.

7. Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool

accidently touches the positive battery terminal or wire. The risk of such shock is

reduced when the ground lead is removed during installation and maintenance.

Recommended Engine Oil and Battery Type

When replacing batteries, use only the recommended battery for your generator, see Table 3-1.

Table 3-1

MODEL

SUMMER WINTER

OIL CAPACITY

RECOMMENDED BATTERY

MODEL

SUMMER

OIL

WINTER

OIL

OIL

CAPACITY

qt (liter)

RECOMMENDED

BATTERY

PC32Ri SAE. 30 5W/30 0.63 (0.6) Interstate YTZ7S − 12Volt − 6 AmpHour

PC43RI SAE. 30 5W/30 1.0 (1.0) Interstate YTX14AHL−BS − 12Volt − 12 AmpHour

Use of Electric Motor Loads

Electric motors require much more current (amperes) to start them than to keep them running.

Some motors, particularly split−phase motors are very difficult to start and require 5 to 7 times

more current to start them. Repulsion−induction type motors are the easiest to start and normally

only require 2 to 3 times as much current to start them.

Most fractional horsepower motors take about the same amount of current to start them and

keep them running. This is true whether they are the repulsion−induction type motor, capacitor

type motor, or the split−phase type motor.

Other factors that influence the amount of current needed to start a motor are:

1. The type of load connected to the motor. If the electric motor is connected to a hard

starting load such as an air compressor it will require more starting current. If the same

electric motor is connected to a light load such as a heater or power saw it will require

less starting current.

2. The brand or design of the electric motor. The expected starting current for a

particular size motor will vary depending on the brand of the electric motor as well as

the type of electric motor (Split Phase, capacitor, Repulsion−induction type, etc.)

3. The condition of the electric motor. A clean motor with free turning bearings will

require less starting currents than a similar type motor that is dirty and the bearings are

not as free turning as they used to be.