GB - 33

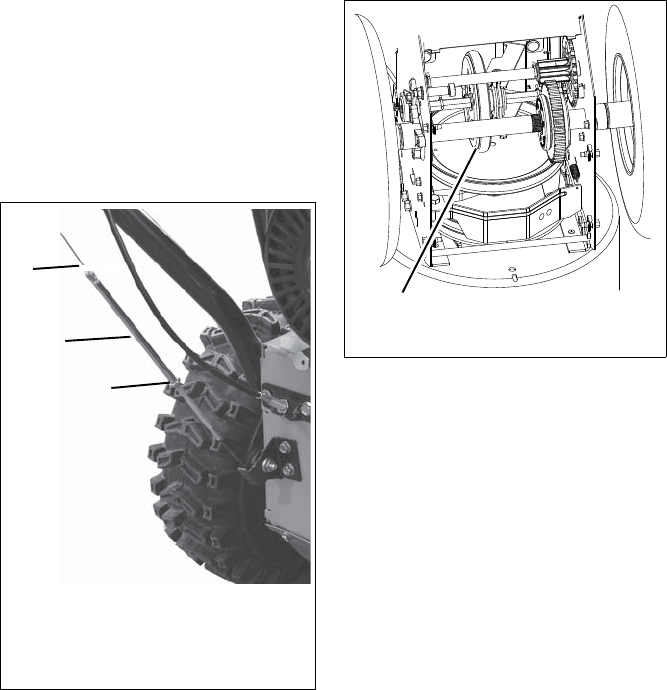

4. To adjust traction clutch (Figure 43):

a. With the traction drive clutch

lever disengaged, loosen the jam

nut on the cable adjuster.

b. Turn the adjuster body up the

cable to decrease the distance

between the clutch lever and

handlebar.

c. Turn the adjuster body down the

cable to increase the distance

between the clutch lever and

handlebar.

5. Check the traction clutch lever distance

and repeat adjustment steps if

necessary.

6. Tighten the jam nut on the traction cable

adjustor body.

7. With the clutch disengaged, check that

there is more than 1/32 in. (0.8 mm)

clearance between friction disc and

drive plate assembly (Figure 44).

IMPORTANT: If traction clutch cannot be

adjusted within specified range, see your

Dealer for repairs.

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove old attachment drive belts:

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Remove belt cover and chute gear cover

(921017, 018) (Figure 45).

3. Rotate discharge chute all the way to the

left (as viewed from the operator’s

position).

4. 921017, 018: Remove hair pin under the

control panel connecting the discharge

chute rod to the chute rotation lever and

slide the discharge chute rod forward.

921011, 012, 013, 014, 015, 016, 019,

020: Remove spring pin from chute

crank and separate.

IMPORTANT: Disconnect chute lock cable

and deflector cable, if equipped (921017,

018).

5. Remove belt finger (Figure 41).

6. Remove attachment drive belt from

engine sheave (it may be necessary to

turn engine sheave using recoil starter

handle).

IMPORTANT: To avoid bending bottom cover

when tipping unit apart, support handlebars

firmly or tip unit up on housing and remove

bottom cover by removing six cap screws

before separating unit.

7. Support Sno-Thro frame and housing.

Figure 43

OS7208

1. Traction Clutch Cable

2. Adjuster Body

3. Jam Nut

2

3

1

Figure 44

OS7144

>1/32 in.

(.8 mm)