GB - 24

GENERAL LUBRICATION

IMPORTANT: Wipe each fitting clean before

and after lubrication. Do not wipe gearcase

filler plug; wiping the gearcase filler plug may

remove thread sealant and cause leaks.

IMPORTANT: DO NOT allow grease or oil to

get on friction disc, friction plate or belts.

NOTE: Apply Ariens Hi-Temp Grease or

equivalent to the lubrication fittings. See

SERVICE PARTS on page 35.

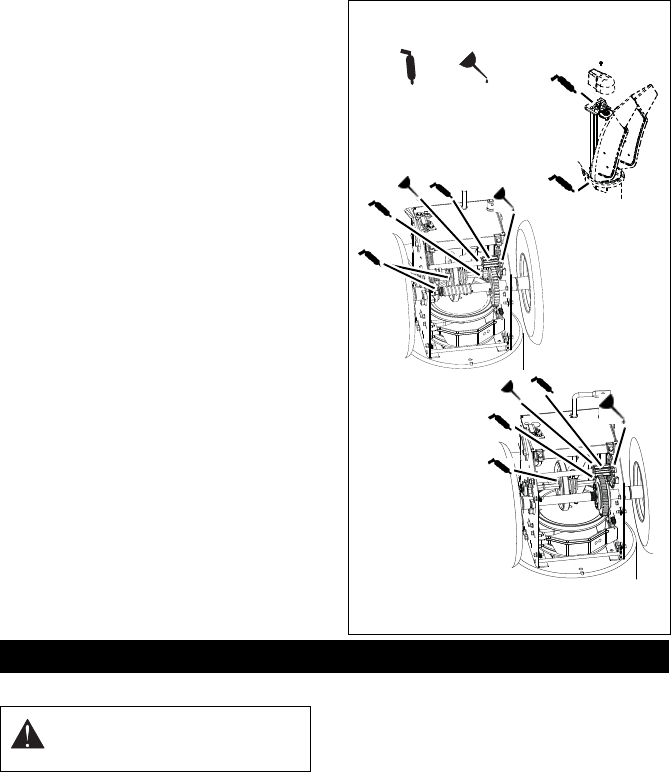

Sno-Thro should be lubricated (Figure 23) at

beginning of season or every 25 operating

hours.

SCRAPER BLADE

IMPORTANT: Damage to auger/impeller

housing will result if blade wears down too

far.

Scraper blade is adjustable to compensate

for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support

housing and loosen nuts retaining blade.

2. Adjust runners to fully raised position

(housing closest to ground).

3. Reposition scraper blade flush with

runners and tighten lock nuts.

RUNNERS

Runners should be adjusted as conditions

require (Figure 24).

1. Position unit on a hard, flat, smooth level

surface.

2. Adjust runners by inserting a spacer of

desired thickness under center of

scraper blade, loosen runner hardware,

slide runners to flat surface. Allow 1/8 in.

(3 mm) between scraper blade and hard

smooth surfaces. Allow 1-1/4 in.

(30 mm) between scraper blade and

uneven or gravel surfaces. Retighten

hardware.

NOTE: Keep housing level by adjusting

runners equally.

Figure 23

Oil

Grease

OS7136

OS7141

OS7142

921005

921004, 006,

007, 008, 009

921004, 006,

007, 008, 009

SERVICE AND ADJUSTMENTS

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.