GB - 21

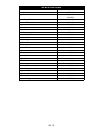

Check Attachment Brake (Figure 29)

1. With the clutch lever disengaged, brake pad must

contact attachment belt. With clutch lever

engaged, brake pad must be more than 1/16 in.

(1.6 mm) from belt. If there is more than 1/16 in.

(1.6 mm) gap, go to Check Belt Finger Clearance

(Figure 30) on page 21. If there is less than 1/16

in. (1.6 mm) gap, go to Step 2.

2. If there is less than 1/16 in. (1.6 mm) gap

between brake pad and belt, follow these steps:

a. To increase brake pad gap, loosen idler

adjustment nut, and move idler away from

belt. Position idler to achieve a 1/16 in. (1.6

mm) minimum brake pad gap and a 1/2 – 7/8

in. (12.7 – 22.2 mm) gap between the plastic

roller and the frame.

b. Check the clutch cable spring extension and

adjust as necessary to achieve a 1/2 – 9/16

in. (12.7 – 14.3 mm) spring extension.

c. If the cable needed adjustment, recheck gaps

described in step 1. Repeat steps as

necessary until brake clearance, roller gap

and spring extension are within specified

ranges.

IMPORTANT: If adjustments cannot be brought into

specified ranges see your Dealer for repairs.

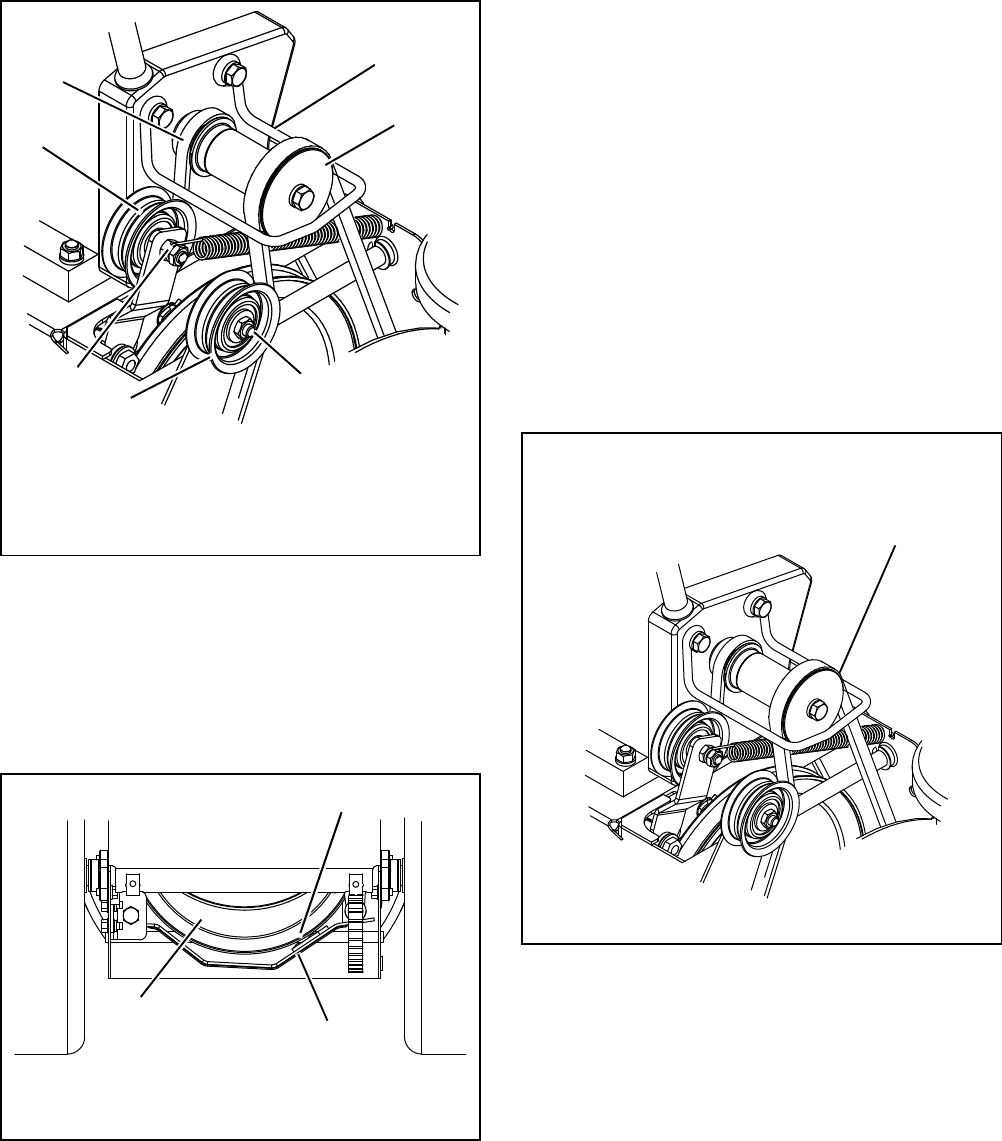

Check Belt Finger Clearance (Figure 30)

1. With clutch lever engaged, the belt finger located

opposite the belt idler must be less than 1/8 in. (3

mm) from belt, but not touching the belt.

To adjust belt finger, loosen the bolts and move

the finger to the proper position. Tighten the bolts

and recheck the belt finger clearance.

2. Replace the belt cover.

TRACTION DRIVE CLUTCH ADJUSTMENT

If drive slips, adjust traction clutch to compensate for

friction disc wear.

To test traction clutch (Figure 31):

1. Put unit in first forward speed.

2. Without engine running, push unit forward while

slowly moving the traction drive clutch lever

toward the handlebar.

3. Measure distance between lever and handlebar

when the wheels begin to brake. If distance is not

7-1/2 – 8 in. (19.0 – 20.3 cm), adjust the traction

clutch.

Figure 28

OS8090

1. Engine Sheave

2.Traction Drive Belt

3.Traction Belt Idler

4.Attachment Idler Nut

5.Attachment Belt Idler

6.Belt Finger

7.Traction Belt Idler Nut

2

3

4

5

6

7

1

Figure 29

OS8092

Minimum of 1/16 in. (1.6 mm)

1.Brake Arm and Pad

2.Attachment Pulley

1

2

Figure 30

OS8067

Check belt finger clearance here. With the

attachment clutch engaged, there should be

less than 1/8 in. (3 mm) clearance between the

belt and the belt finger. The belt finger should

not touch the belt.