Operation

1) Before filling hopper, make sure spread-

er handle lever is in the “OFF” position.

Always fill spreader on sidewalk or drive,

not on the lawn.

2) Loosen rate control knobs and move the tie

bar to setting recommended for the product

applied. Retighten knobs. If setting is not

known, refer to “Determing Application Rates”

section of this book.

3) Always push spreader, do not pull. Start

spreader in motion and as it passes over

the area to be treated, push handle lever to

the “ON” position. Close handle lever at the

end of each pass.

4) Operate spreader at 3 MPH pace. (33.3

feet in 7.5 seconds)

5) Apply two header strips at each end of

area to treated and then proceed lengthwise

between the header strips. Be sure to over-

lap the wheel tracks slightly to prevent

streaking.

6) When applying lime, do not use lime-

stone that is so finely ground that it will pack

inside the hopper, or use hard, abrasive par-

ticles which will damage the spreader. Use

only compacted, free-flowing, non-abrasive

lime products.

Determining Application Rates

PROCEDURE EXAMPLE

1) The manufacturer will recommend The contents of this

coverages on the product package. package (25 lbs.)

Generally, it is stated as applying covers 2,000 square

a certain number of pounds of feet.

product per 1,000 square feet.

2) Determine the amount of material 2,500 divided by 2,000

in pounds to cover 100 square square feet = 1.25 lbs.

feet. Add two zeros to weight

of bag and divide that by the

square foot coverage.

3) To change the decimal portion 0.25 x 16 oz. = 4 oz.

of answer in step #2 to ounces, Total weight = 1 lb.- 4 oz.

multiply decimal portion by 16.

4) On a clean sidewalk or driveway, measure out 33.3 feet - the

distance required to cover 100 square feet.

5) Add a measured amount of product to the spreader - 2 to 3

times the recommended rate. Operate spreader at a brisk walk-

ing speed (3 mph of 33.3 feet in 5 seconds) over the measured

distance. Empty the spreader and weigh the amount left.

Compare with the beginning amount; the difference is the

amount applied. Adjust the setting up or down to achieve the

correct application rate.

The following procedure provides a means of accurately deter-

mining drop spreader settings when settings do not appear on

the package, or to “fine tune” the manufacturer’s recommended

settings. Spreader rates can vary due to walking speed, condi-

tion of turf, humidity, physical characteristics of the product

being applied, or condition of the spreader. It is good practice to

double check settings using the following method:

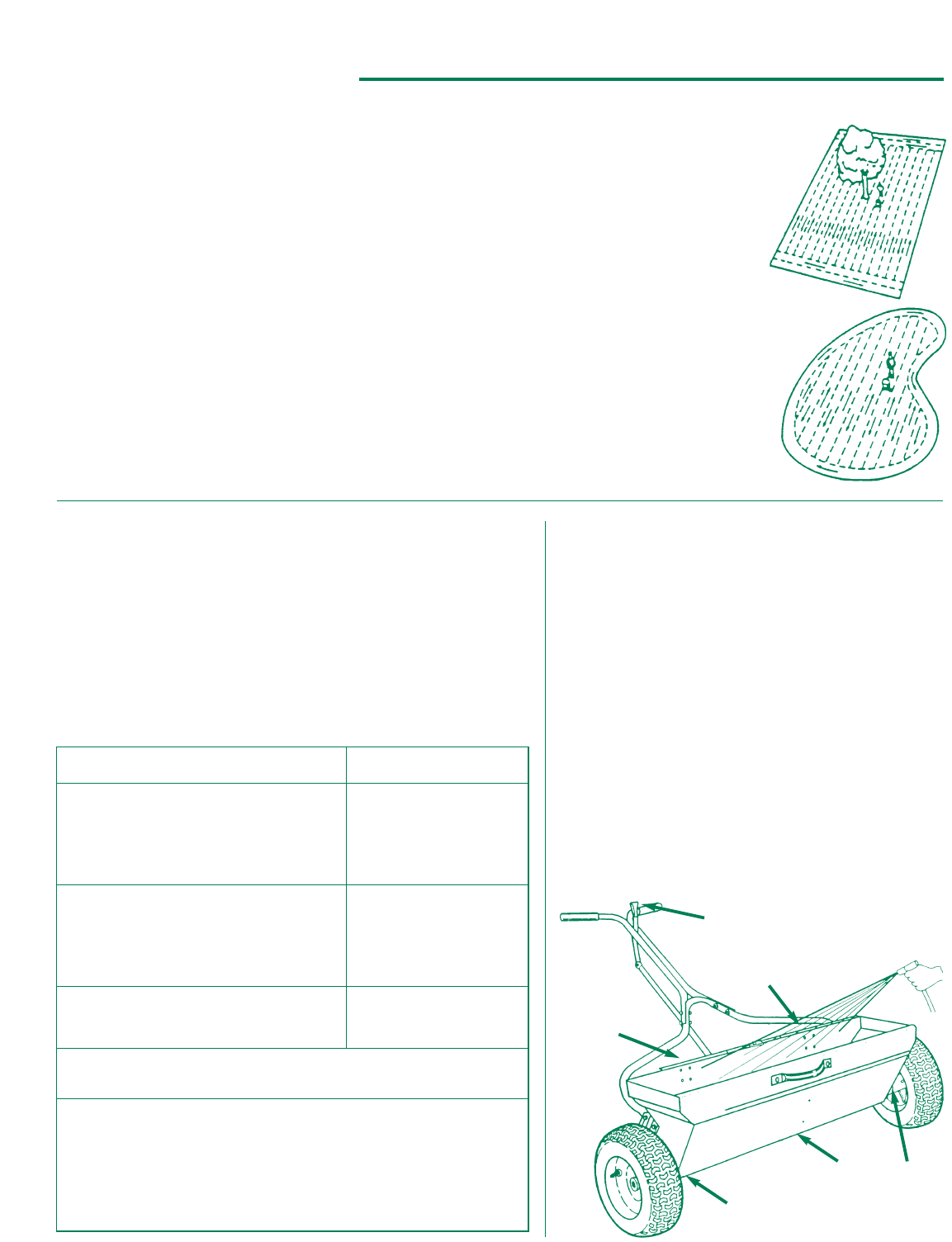

Maintenance

1) Never store unused material in spreader.

Return unused product to its original container.

2) Set rate slide on the highest number, open

spreader and spin wheels to remove excess

material.

3) Wash out hopper thoroughly after each use to

remove material clinging to surfaces. Pay close

attention to area between the shutoff bar and

hopper. Allow spreader to completely dry.

4) Oil bottom of hopper, control housing spring and

agitators at the center bearing. Lubricate axle.

“Open”

Oil

Oil

Oil

Grease

Grease

3