7

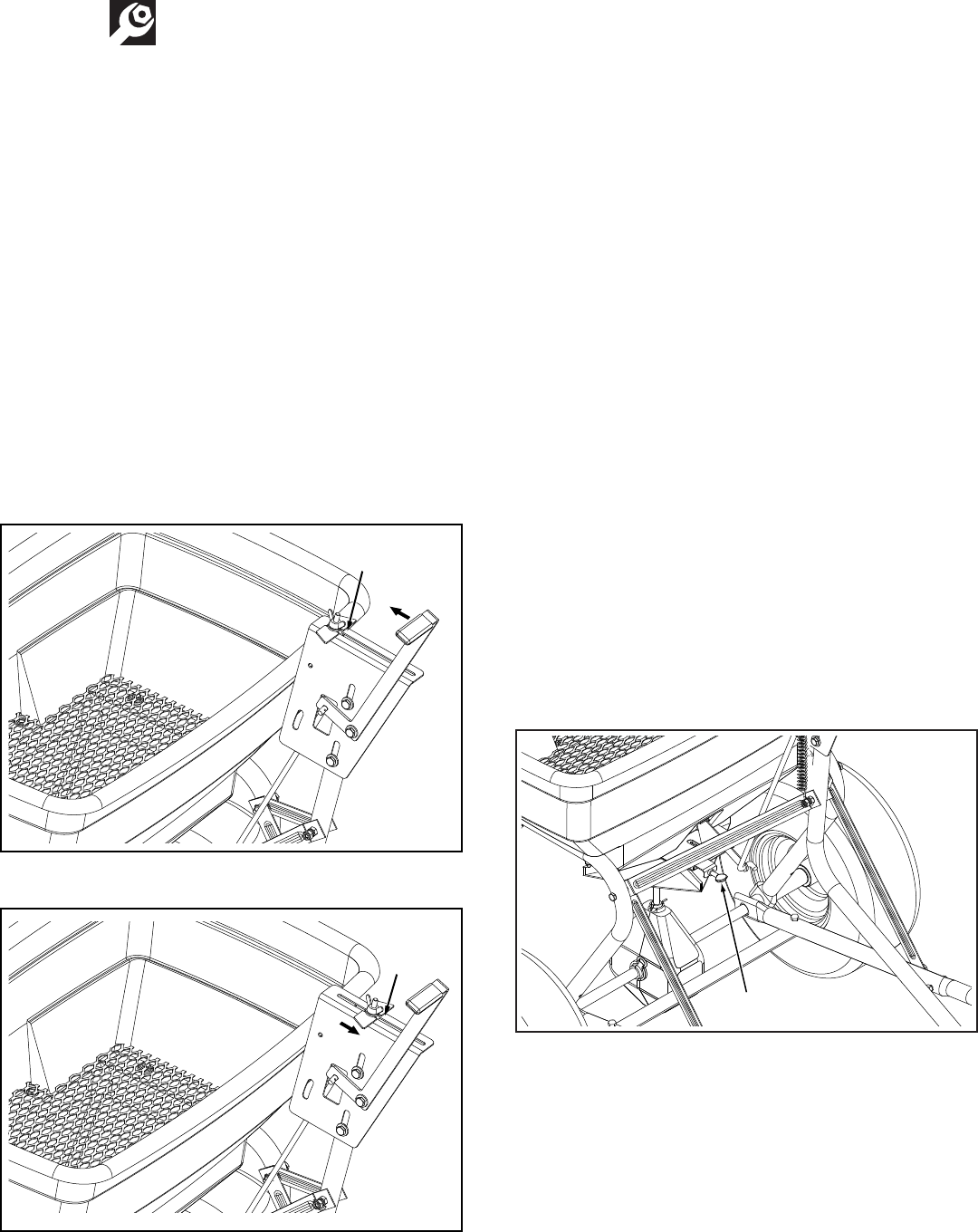

CALIBRATING FLOW CONTROL ARM

Flow control mounting bracket (gure 16 and 17)

a. Setadjustablestopat"OFF"position.Moveowcontrol

arm against adjustable stop.

b. Slideowcontrolmountingbracketalongcontroltube

until closure plate in bottom of hopper just closes.

c. Snugthenutsjustenoughtoholdowcontrolmounting

bracket in place.

d. Setadjustablestopat"5".Withowcontrolarmresting

against stop, verify that closure plate is open about half

way.

e. Ifclosureplateisnotopenabouthalfway,slideow

control mounting bracket up or down control tube until

closure plate will open about half way at "5" and will

close completely when arm is pushed past adjustable

stop to "OFF" position. Tighten the 5/16" nylock hex

nuts.

"5"

"OFF"

FIGuRE 16

FIGuRE 17

OPERATION

HOW TO uSE YOuR SPREADER

SETTING THE FLOW CONTROL

(Refertogure16and17)

1. Loosen the nylon wing nut, set the adjustable stop to

thedesiredowratesettingandretightenthewingnut.

The higher the setting number, the wider the opening

in the bottom of the hopper.

2. Refer to the Application Chart on page 8 and to the

instructions on the fertilizer bag to select the proper

owratesetting.

3. Pulltheowcontrolarmfromthe"OFF"positionand

rest it against the adjustable stop for the “ON” position.

Push the ow control arm past the stop, toward the

hopper for the “OFF” position.

uSING THE PATTERN ADJuSTMENT PLATE

The pattern adjustment plate is used to adjust the ow

of material being spread to the left or right side. The

pattern adjustment plate is the bottom stainless steel plate

underneath the hopper.

The adjustment of the pattern plate is sensitive. It is

recommended that you test your spread pattern in a small

arearst.

1. Toadjusttheowtobeheaviertotheleftside,tighten

the thumbscrew so the plate will not pull out as far.

Seegure18.

2. To adjust the ow to be heavier to the right side,

loosen the thumbscrew so the plate will pull out farther.

Seegure18.

FIGuRE 18

THUMB SCREW

FIGuRE 11

TIGHTEN FASTENERS

Tighten the nut (H) and then loosen

justenoughthattheowcontrolarm

moves freely.