Manual Page 10

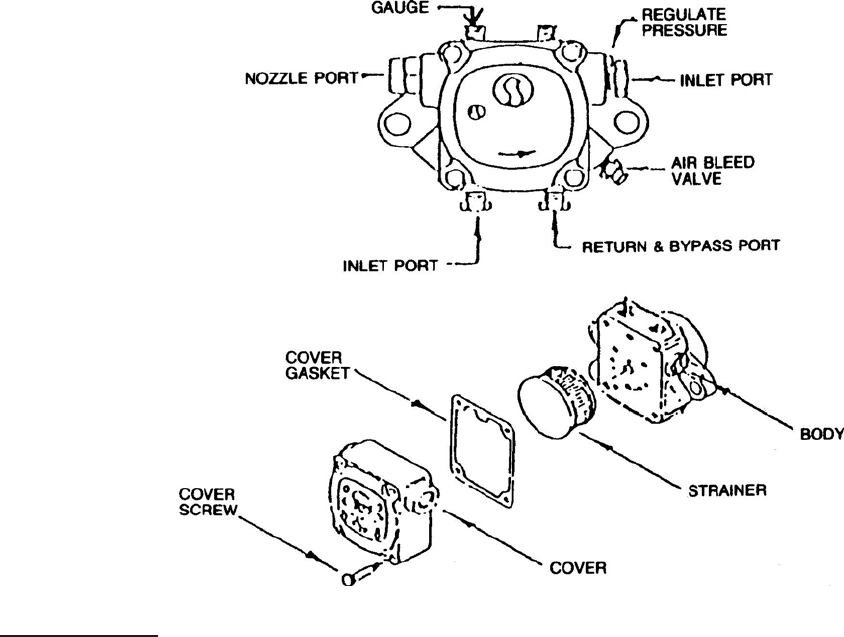

6. FUEL PUMP: To bleed air out of fuel pump, open air bleed valve on side of fuel pump. Turn

machine and burner ON. When fuel looks clear (NOT FOAMING), close air bleeding valve. Air is out

of fuel lines and fuel pump.

A. To check fuel pressure, plumb a 200 PSI gauge into the port marked gauge. DO NOT USE

BLEED VALVE PORT TO CHECK FUEL PUMP PRESSURE.

B. To adjust fuel pressure, insert a small flat screwdriver into pressure regulator slot and turn

clockwise to increase pressure and counter clockwise to decrease pressure. One full turn is about

10 PSI. Use a pressure gauge. normal operating pressure is 140 PSI. DO NOT EXCEED 150

PSI.

C. Service the fuel pump once every 50 hours or 3 months by cleaning the fuel strainer screen.

A clogged strainer or fuel filter will cause fuel pump starvation and dry the fuel pump up.

The ONLY lubrication the fuel pump has is the fuel that runs through it. KEEP IT CLEAN for

longer fuel pump life.

WINTERIZING

1. Shut off and disconnect the water supply.

2. Drain float tank.

3. Install antifreeze kit (available through local dealer.)

4. Remove nozzle from wand, and insert pick up hose and soap line into a bucket of 50% solution of

antifreeze. Pump antifreeze through machine. Open and close trigger gun a few times to

winterize unloader system. When antifreeze flows from the wand, shut the pump off. Disconnect

antifreeze kit.

NOTE: BEFORE attempting to wash ANY painted surface, pump anti-freeze out of machine into a

clean bucket and save for next use.