Section 5: Maintenance

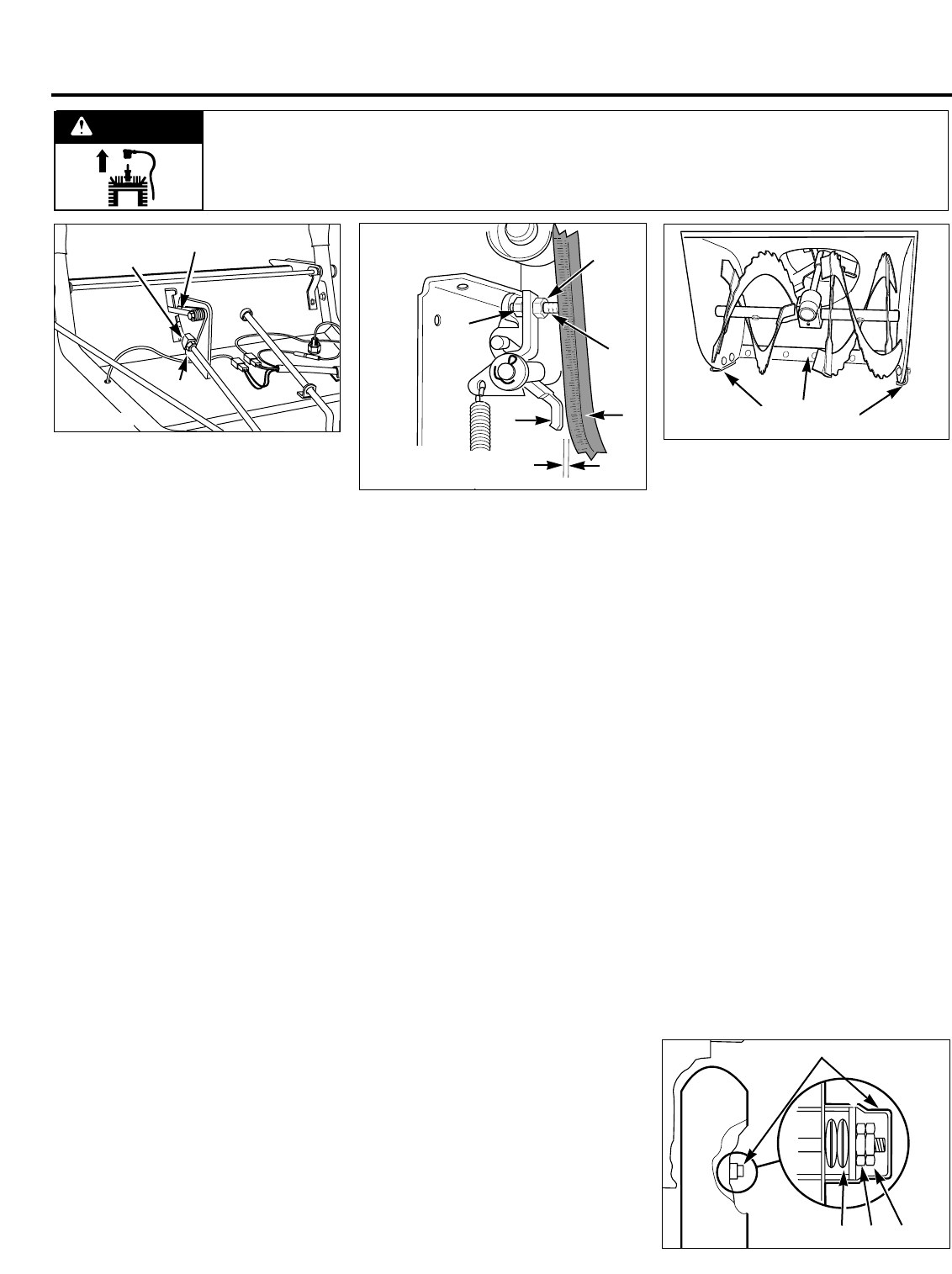

To adjust brake arm:

1. With engine stopped and spark plug

wire disconnected, remove screws and

washers (AB, Figure 5-1) and remove

belt cover from unit.

2. Squeeze the auger drive control lever

(AL, Figure 5-7) against handlebar.

3. Using a flashlight, look down through

the pulleys and belts (Figure 5-6).

Check gap between brake arm (A,

Figure 5-11) and belt (B). The gap

should measure between 1/16" and

1/8" (1.5–3 mm).

4. To adjust gap: Loosen nut (C, Figure

5-11). Hold bolt (D) in place and rotate

nut (E) until proper clearance is ob-

tained. Secure nut (C).

5. Reinstall the belt cover.

SKID SHOES/SCRAPER BLADE

The unit should be adjusted so the collec-

tor (auger/impeller) housing and the

scraper blade (N, Figure 5-12) are 1/8" (3

mm) above the surface to be cleared. If

the unit is used to clear gravel or uneven

surfaces, this adjustment should be in-

creased so gravel or other foreign objects

are not scooped into the auger. To adjust

the collector housing/scraper blade height:

1. Move the unit onto a level surface.

2. With the engine stopped and the spark

plug wire disconnected, loosen the

hardware securing the skid shoes (M,

Figure 5-12).

3. Adjust skid shoes until they are in the

correct position to support collector

(auger/impeller) housing and scraper

blade (adjust both skid shoes equally

to prevent uneven snow removal).

4. Tighten the hardware to lock the

skid shoes (M, Figure 5-12) into the

proper position.

5. The scraper blade (N, Figure 5-12) can

also be adjusted. Adjust scraper blade

(N) at carriage bolts. Adjust bottom

edge of scraper blade so it is parallel

with bottom edge of auger.

SLIP DIFFERENTIAL

ADJUSTMENT

1. With the engine stopped and the spark

plug wire disconnected, remove hub

cap (AQ, Figure 5-13) at end of wheel

shaft on right side of unit.

2. Remove outer (AR, Figure 5-13) and

inner jam nuts (AS) and both pairs

(four single disc springs) of disc

springs (AT). Inspect springs and re-

place them if they are worn.

3. Reinstall disc springs (AT, Figure 5-

13) and inner jam nut (AS). Tighten

jam nut (AS) by hand until it contacts

the disc spring, then tighten (AS) 1 to

1-1/4 turns more. DO NOT force nut

more than 1-1/4 turns or differential

will not work (unit will be difficult to

turn).

4. Secure the inner nut (AS, Figure 5-13)

in place, while tightening the outer nut

(AR).

5. Reinstall cover (AQ, Figure 5-13).

OFF-SEASON STORAGE

When storing the unit for more than 90

days, follow these procedures to help keep

the unit in good condition for future use:

• Clean dirt, grime and grease from the

unit and engine.

• Perform routine lubrication as in-

structed earlier in this section.

• Service the engine according to the

Storage instructions in the engine

manual. Add a fuel stabilizer to the

fuel tank, according to the instructions

provided with the stabilizer. Change

the engine oil.

• On units so equipped, rotate the fuel

shut-off valve to the “OFF” position.

• Thoroughly inspect the unit for any

loose, damaged, or missing parts.

Repair or replace the parts as neces-

sary. Check all nuts, bolts and other

fasteners for tightness and tighten as

necessary.

• Touch-up scratches and chipped paint

to prevent corrosion.

• Store the unit on a level surface, out of

the reach of children.

Figure 5-10

N

AV

ZZ

Figure 5-11

A

B

D

E

C

1/16" - 1/8"

1.5 - 3 mm

Figure 5-12

N

M

M

20

Figure 5-13

AQ

AT

AS

AR

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to

a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING