11

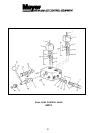

DUAL FLOW VALVE/STAND INSTALLATION INSTRUCTIONS

1. IMPORTANT: A pipe joint sealant

compatible with hydraulic oil must be

applied to all screw fittings. (Teflon Tape

Sealant Is Not Recommended)

2. Hose ends connected to flow valve must

be of the swivel type.

3. CAUTION: Over tightening of the fittings

in flow valve may cause damage to

valve body

4. Approximately 8" of hose slack must be

realized between the flow valve and

valve stand after the flow valve has been

completely plumbed. If this condition

does not exist after the plumbing has

been completed, removal of valve will

require hoses to be removed at opposite

end of valve.

5. Assembly of valve on stand:

a. Cut a 5" x 5" square opening in floor

board of truck where the valve stand is

to be located.

b. Bolt valve stand halves together forming

a box over the 5" x 5" square opening.

NOTE: When bolting valve stand halves

in place, make sure holes in flanges

align with holes in flange plate.*

c. Bolt flange plate to VALVE (Use (2)

1/4" x 3" bolts, lockwashers, etc.)

d. Insert hoses through floor opening and

valve stand and connect appropriate

hoses (see instructions #1 thru #4) to

flow valve.

e. Bolt flange plate to valve

stand flanges.