Mounting the Scale / Fitting the Scale Guard

Length

2500mm

3000mm

3500mm

4000mm

4500mm

5000mm

5500mm

6000mm

6500mm

7000mm

7500mm

8000mm

8500mm

9000mm

9500mm

10000mm

10500mm

11000mm

No. of Scale

Supports

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

6

6

6

Left Side (A)

850mm

1100mm

1350mm

1500mm

1125mm

1250mm

1350mm

1500mm

1300mm

1400mm

1500mm

1600mm

1410mm

1500mm

1580mm

1420mm & 2840mm

1500mm & 3000mm

1570mm & 3140mm

Right Side (B)

850mm

1100mm

1350mm

1500mm

1125mm

1250mm

1350mm

1500mm

1300mm

1400mm

1500mm

1600mm

1410mm

1500mm

1580mm

1420mm & 2840mm

1500mm & 3000mm

1570mm & 3140mm

Mid Position

of Travel (B)

-

-

-

-

2250mm

2500mm

2750mm

3000mm

-

-

-

-

4250mm

4500mm

4750mm

-

-

-

Left Side Position

of Travel (C)

-

-

-

-

-

-

-

-

650mm

700mm

750mm

800mm

1410mm

1500mm

1580mm

710mm

750mm

785mm

Right Side Position

of Travel (C)

-

-

-

-

-

-

-

-

650mm

700mm

750mm

800mm

1410mm

1500mm

1580mm

710mm

750mm

785mm

FROM FIXING BRACKET

Table 1

Newall Measurement Systems

9

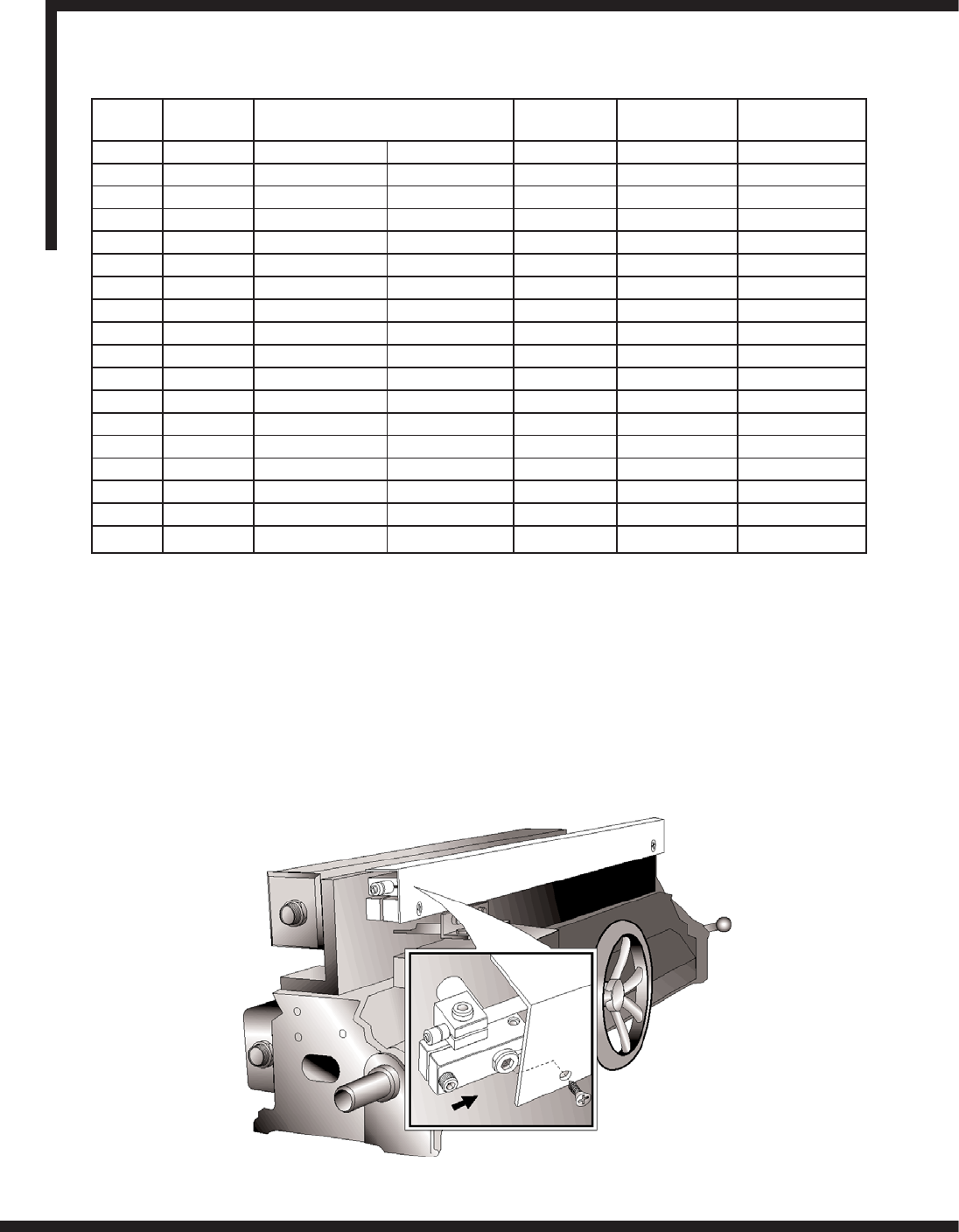

5.0 FITTING THE SCALE GUARD

Each encoder includes a protective guard. This aluminium guard is intended to protect the scale from impact damage.

The guard can be attached to the machine casting or by means of the scale support pillars (Refer to Figure 5.1).

To fit the guard to the support pillars, measure and mark off the distance between the center of each pillar. For SHG,

drill two 8.5mm (3/8") holes at either end of the guard. The guard can be attached to the pillars by using the button

head screws provided. After the guard is attached, move the machine axis to both extents of its travel ensuring that the

guard does not interfere with or rub against the reader head.

Figure 5.1 - Fitting the scale guard (example shown using a Spherosyn™ scale)