HD 4000 C / HD 6000 C

English

5.956-648 A10369 (06/98)

G. System Installation

G1

1. Placement

The system must be installed in dry indoor

surroundings free from explosion hazard.

The components shall be placed on firm

and level ground, and the system must be

easily accessible for the purpose of

maintenance procedures. The room

temperature must not exceed 40 °C.

Additional height-over-floor obtained

through the use of the component feet

(140 mm length) facilitates maintenance ac-

cess. In the absence of sufficient space the

elastic feet can be used by themselves.

2. Connections

The water and waste-water connections, as

well as the connection with the electrical

mains network may only be carried out by

licensed and authorised professional

contractors pursuant to local regulations. In

the Federal Republic of Germany the

following regulations apply:

n VDMA guideline, standardised leaflet

24416 “Fixed-Installation High-Pressure

Cleaning Systems”

n VDE Regulations (VDE = Professional

Association of German Electricians)

n Regulations issued by local utility

companies

Both the required water supply and the

electrical mains network connection must

be configured for permanent operation. The

specified connective load values are stated

in the Specifications.

The water supply must be equipped with a

shutoff valve, and must be connected with

the high-pressure by means of a flexible

high-pressure hose. Insufficient supply line

cross section or insufficient admission

pressure will result in water starvation.

To prevent pump damage, a low-water

condition will automatically result in system

shut-down.

AUTHORISED PROFESSIONAL PERSONNEL ONLY

In the event of excessive admission

pressure or the occurrence of pressure

peaks in the mains network, the installation

of a pressure regulator upstream of the

system is mandatory.

The motor cooling circuit within the system

requires a separate cold-water connection.

A water drain must be present at the

installation site.

3. High-pressure Installation

The link between the fixed-installation pipe

network and the system must be executed

in the form of a flexible high-pressure hose

connection.

The permanent pipe network installation

must consist of as many straight runs as

possible. All high-pressure tubing must be

installed pursuant to regulations, using

vibration-dampened strain relief and fixed

pipe or tubing clamps, while allowing for

longitudinal expansion/contraction due to

the effects of temperature and pressure.

To keep pressure losses in the high-

pressure lines as low as possible, the

following recommendations should be used

as mandatory guidelines:

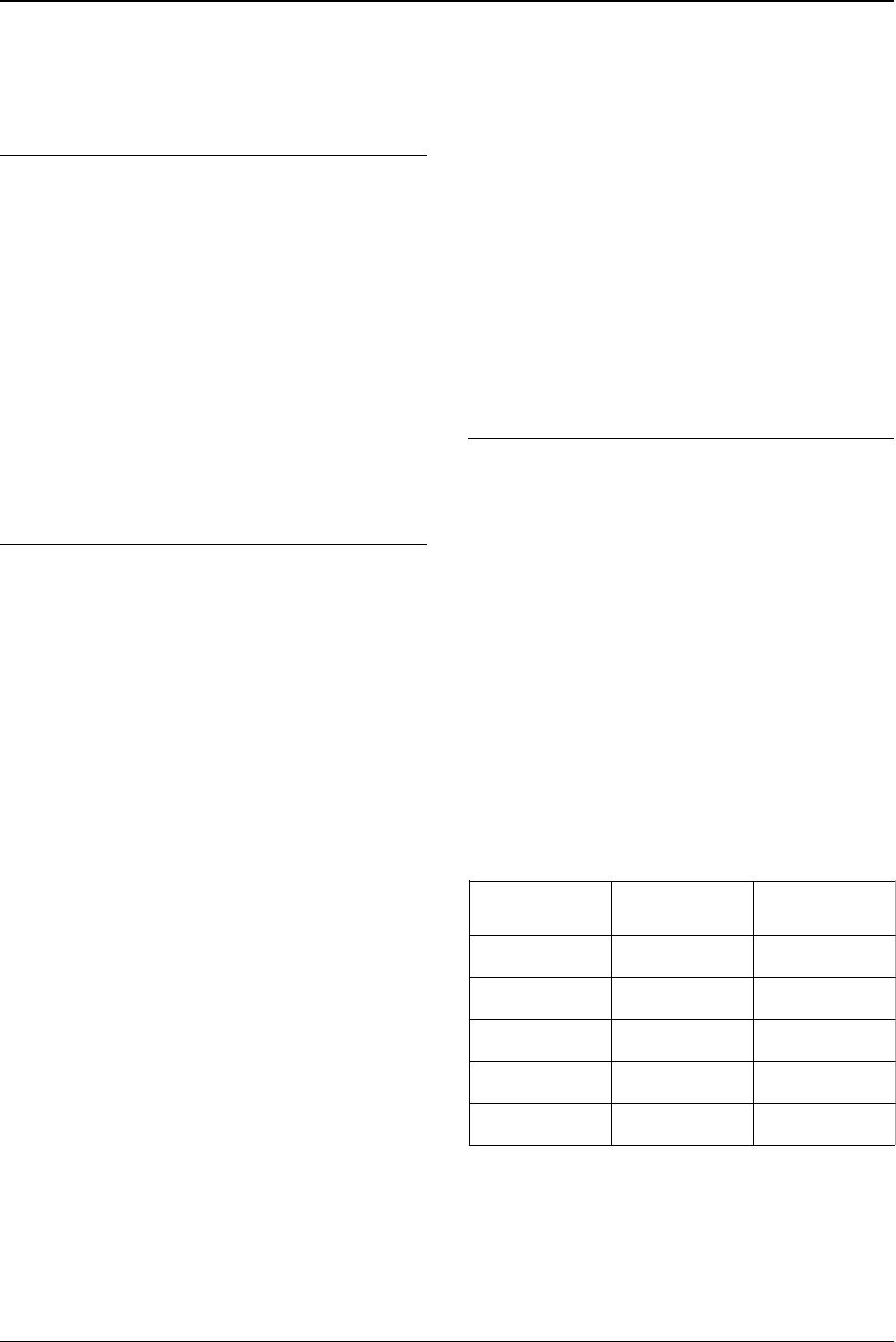

Delivery

volume

Tubing line Hose size

1000 L/h NW 10 (3/8") NW 8

2000 L/h NW 15 (1/2") NW 12

3000 L/h NW 15 (1/2") NW 12

4000 L/h NW 20 (3/4") NW 16

6000 L/h NW 25 (1") NW 20

It should be understood that the above

guidelines still require additional allowances

for the overall tubing length, the number of

directional changes and armatures.