PR-Series Operator’s Manual-E/F 29

Service

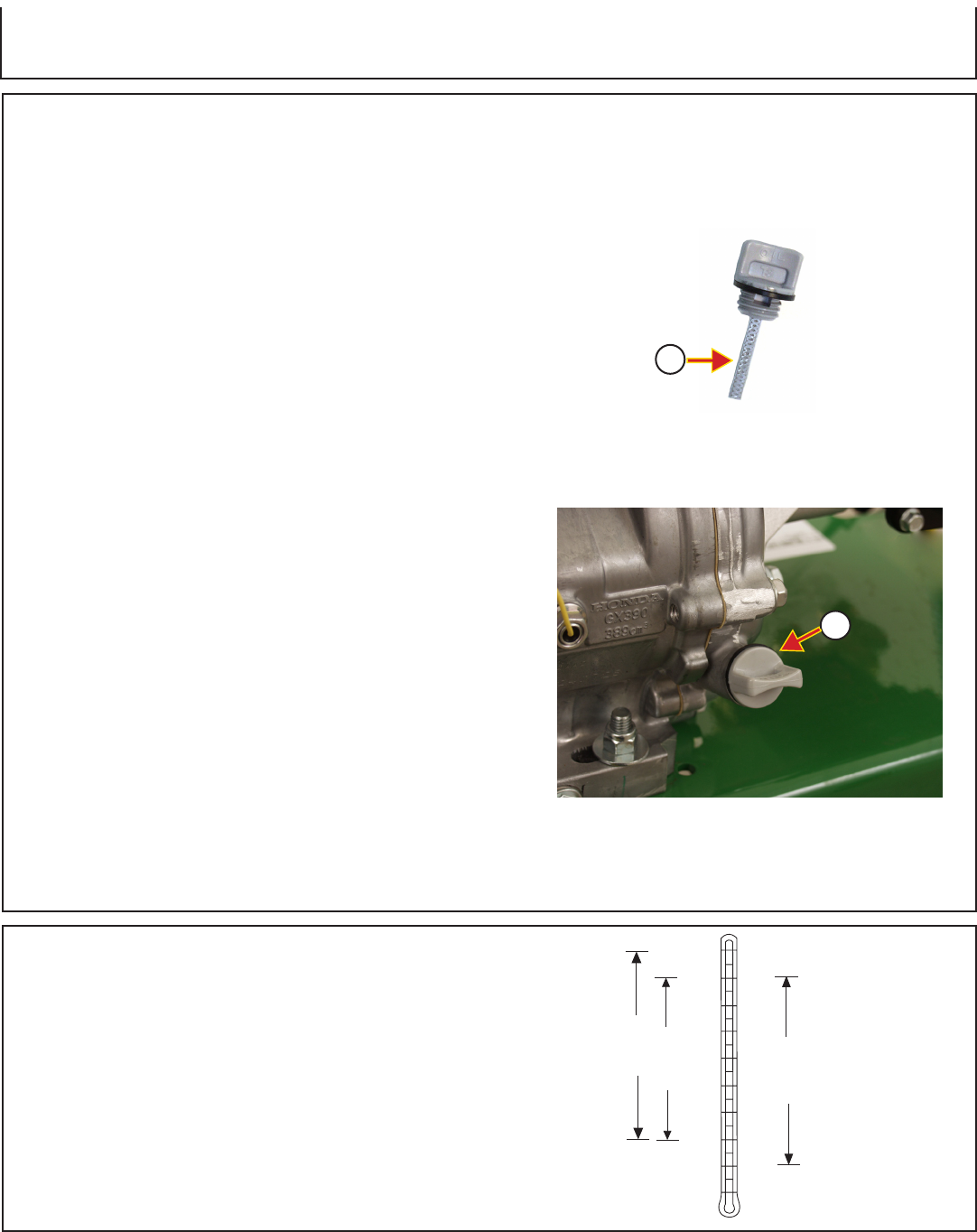

A

GASOLINE ENGINE OIL

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Other oils may be used if they meet one or more of the

following:

•API Service Classication SH

•API Service Classication SG

•CCMC Specication G4

•CCMC Specication G5

CHANGING ENGINE OIL

IMPORTANT: Change oil after rst 20 hours of operation

and every 100 hours thereafter.

1. Put unit on level surface.

2. Run engine a few minutes to warm oil.

3. Stop engine.

4. Remove oil ller cap (A) and drain plug (C) and drain oil into

container. Do not pollute, dispose of waste oil properly.

5. Install drain plug (C). Fill with oil to top of threads. Install

cap. Oil capacity is :

-PR-3000GS .............. 0.6L (0.63 qts.)

-PR-3000GH .............. 0.6L (0.63 qts.)

-PR-3400GS .............. 1.0L (1.1 qts.)

-PR-3400GH .............. 1.1L (1.2 qts.)

-PR-4000GS .............. 1.2L (1.3 qts)

-PR-4000GH .............. 1.1L (1.2 qts.)

DWG13-102299R0

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

CHECK ENGINE OIL

NOTE: All washers are shipped with engine oil. Check

proper level.

1. Stop engine.

2. Place unit on level surface.

3. Remove oil ller cap/dipstick and wipe it clean.

4. Insert ller cap/dipstick into oil ller neck, but DO NOT

screw it in.

5. Remove dipstick. Proper oil level is at midpoint of

dipstick (A). Add oil if necessary to bring oil level to

top of threads (B).

6. Install and tighten cap.

PIC110-102299R0

P05-013107

B