11

SERVICE AND ADJUSTMENTS

IDLE RPM ADJUSTMENT-

• With engine at idle speed, turn the idle adjust screw

slowly counterclockwise until the engine begins to

falter.

• Then raise the engine speed by turning the idle ad-

just screw clockwise until the engine holds a smooth

con stant speed.

ACCELERATION TEST -

• Move throttle control lever from “SLOW” to “FAST”

po si tion. If engine hesitates or dies, turn idle adjust

needle out (coun ter clock wise) 1/8 turn. Repeat test

and con tin ue to adjust, if necessary, until engine ac-

cel er ates smoothly.

High speed stop is factory adjusted. Do not adjust or dam-

age may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOV ER NOR, WHICH IS FACTORY SET FOR PROPER ENGINE

SPEED. OVER-SPEEDING THE ENGINE ABOVE THE FAC TO RY

HIGH SPEED SETTING CAN BE DANGEROUS. IF YOU THINK

THE ENGINE-GOVERNED HIGH SPEED NEEDS AD JUST ING,

CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER,

WHICH HAS PROPER EQUIPMENT AND EXPERIENCE TO

MAKE ANY NECESSARY ADJUSTMENTS.

ENGINE

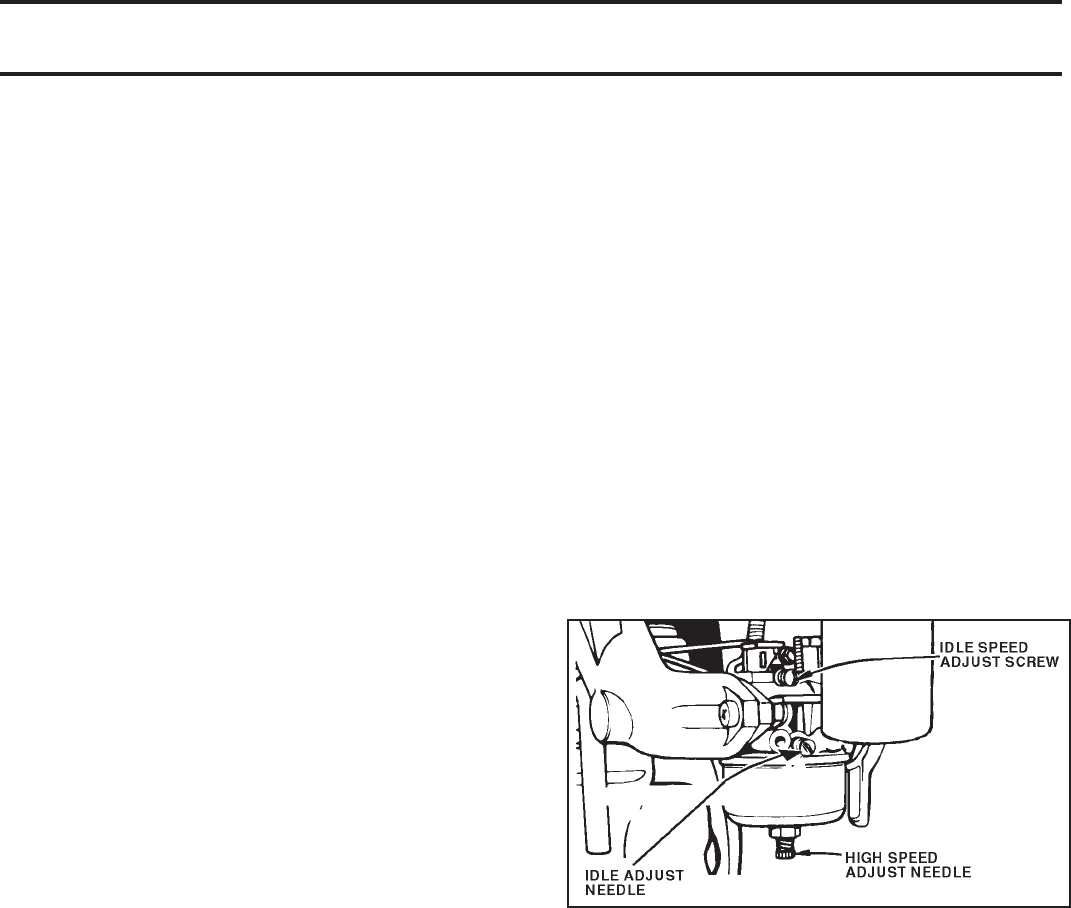

TO ADJUST CARBURETOR (See Fig. 11)

The carburetor has been preset at the factory and ad-

just ment should not be necessary. However, minor ad just -

ments may be required to com pen sate for differences in

fuel, temperature, altitude or load. If the carburetor does

need adjustment, pro ceed as follows.

In general, turning the adjust needles in (clock wise) de-

creas es the supply of fuel to the engine giving a leaner

fuel/air mixture. Turning the adjust needles out (coun-

ter clock wise) increases the sup ply of fuel to the engine

giving a richer fuel/air mixture.

IMPORTANT: DAMAGE TO THE NEEDLES AND THE SEATS

IN CARBURETOR MAY RESULT IF SCREWS ARE TURNED

IN TOO TIGHT.

PRELIMINARY SETTING

• Air cleaner assembly must be assembled to the car-

bu re tor when making carburetor adjustments.

• With engine off turn high speed adjust needle in

(clock wise) closing it fi nger tight and then turn out

(coun ter clock wise) 1-1/2 turns.

• Turn idle adjust needle in (clockwise) closing it fi nger

tight and then out (counterclockwise) 1-1/4 turns.

FINAL SETTING

• Start engine and allow to warm for fi ve minutes. Make

fi nal adjustments with engine running and tine clutch

control lever in “DISENGAGED” position.

• With throttle control lever in “SLOW' position, turn

idle adjust needle(clockwise) until engine begins to

die then turn out (counterclockwise) until engine runs

roughly. Turn needle to a point midway between those

two po si tions.

• With throttle control lever in “FAST” position, turn

high speed adjust needle.

FIG. 11