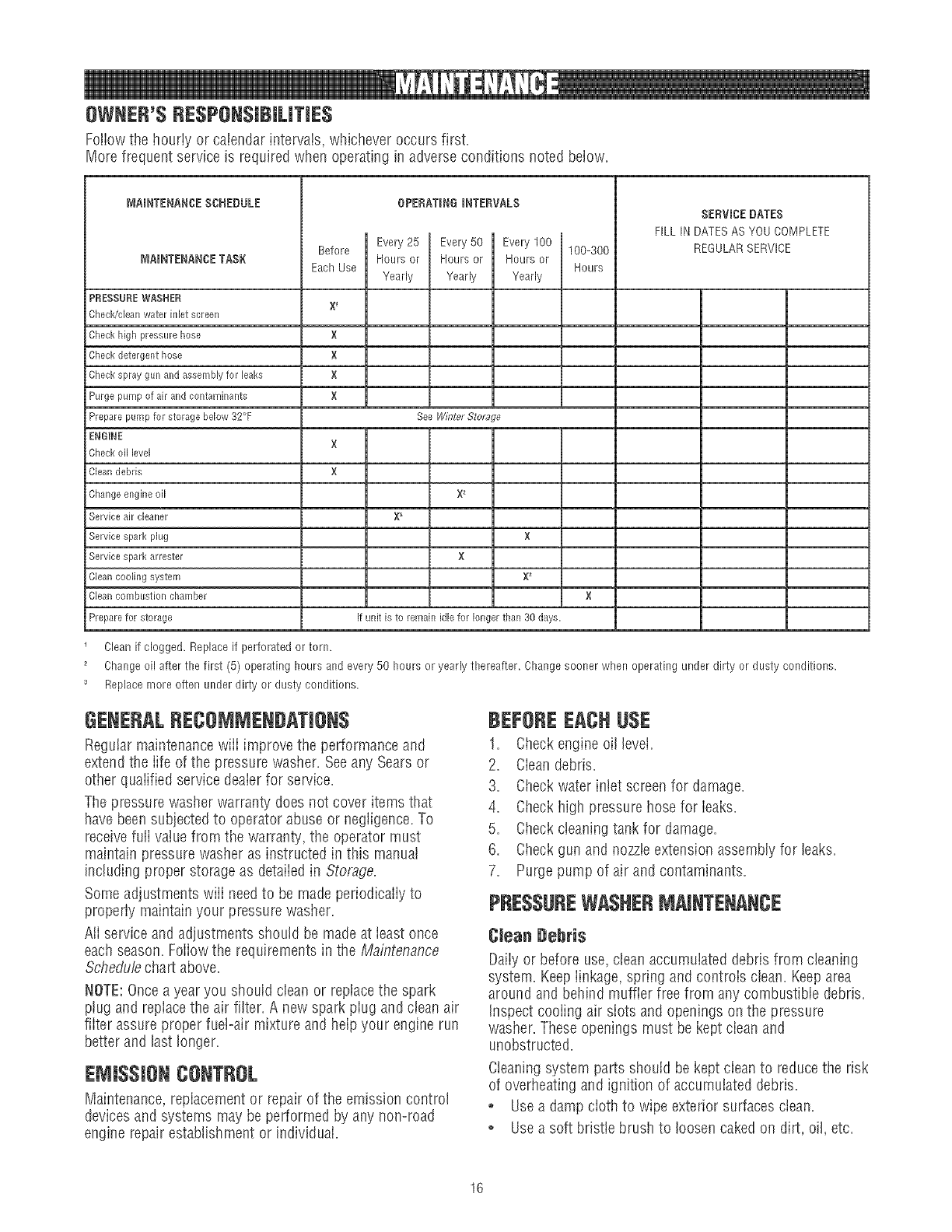

OWNER'SRESPONSiBiLiTIES

Followthe hourly or calendarintervals, whichever occurs first.

More frequent service is requiredwhen operating in adverse conditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSUREWASHER

Chec_Ncieanwater inlet screen

Check high pressure hose

Check detergent hose

Checkspray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Before

EachUse

X 1

}(

N

N

}(

OPERATINGiNTERVALS

I Every25 Every50 Every 100

Hours or Hours or Hours or

Yearly Yearly Yearly

See Winter Storz_ge

100-300

Hours

SERVICEDATES

FILL IN DATESASYOU COMPLETE

REGULARSERVICE

Check oil bye[

Cleandebris

Changeengine oil

Service air cleaner

Service spark plug

Service spark arrester

Cleancooling system

Cleancombustion chamber

Prepare for storage

X

X

X _

X_

X

X

X_

If unit is to remain idle for longer than 30 days,

Cleanif clogged. Replaceif perforated or torn.

Changeoil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

Replacemore often under dirty or dusty conditions,

GENERALRECO 'JMENDATION$

Regularmaintenancewill improve the performanceand

extendthe iife of the pressure washer. Seeany Searsor

other quaiified service deaierfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjectedto operator abuseor negiigence.To

receivefurl vatuefrom the warranty, the operator must

maintain pressure washeras instructed in this manual

including proper storage as detaiiedin Storage.

Someadjustments wiii needto be madeperiodicaliy to

properly maintain your pressure washer.

AtI serviceand adjustments should be madeat least once

eachseason.Follow the requirementsin the Maintenance

Schedu/echart above.

NOTE:Oncea year you should clean or replacethe spark

ptug and repiacethe air filter. Anew spark piug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last Ion@r.

ENIi$$i0N CONTROL

Maintenance,replacementor repair of the emission control

devicesand systems may be performed by any non-road

engine repair establishment or individual.

BEFOREEACHUSE

1. Checkengine oil bvei.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for leaks.

5. Checkcteaningtank for damage.

6. Checkgun and nozzteextension assembly for leaks.

7. Purge pump of air and contaminants.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use,clean accumuiated debris from cbaning

system. Keepiinkage, spring and controis cban. Keeparea

around and behind muffler free from any combustible debris.

Inspect cooiing air siots andopenings on the pressure

washer. Theseopenings must be kept cieanand

unobstructed.

Cleaningsystem parts should be kept cleanto reducethe risk

of overheating and ignition of accumuiated debris.

. Usea dampcioth to wipe exterior surfaces clean.

o Usea soft bdstte brush to loosencaked on dirt, oil, etc.

16