SERVICE AND ADJUSTMENTS

ENGINE SPEED

A CAUTION: ENGINE SPEED WAS PROPERLY AD-

JUSTED AT THE FACTORY AND SHOULD RE-

QUIRE NO ADDITIONAL ADJUSTMENT. DO NOT

ATTEMPT TO CHANGE ENGINE SPEED. IF YOU

BELIEVETHE ENGINE IS RUNNING TOO FAST OR

TOO SLOW, TAKE YOUR PRESSURE WASHERTO

SEARS AUTHORIZED SERVICE CENTER FOR RE-

PAIR AND ADJUSTMENT, CHANGING ENGINE

GOVERNED SPEED WILL VOID ENGINE WAR-

RANTY.

Your pressure washer runs at a constant speed. This

constant operating speed is maintained by a mechanical,

flyweight type, fixed speed governor. DO NOT tryto adjust

the governed speed setting for the following reasons:

,, High engine speeds are dangerous and increase the

risk of personal injury or damage to equipment.

Low engine speeds impose a heavy load on the engine

when sufficient engine power is not available and may

shorten engine life.

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust the

valve clearance in the engine.

When adjusting valve clearance, engine should be at room

_.mperature and piston should be at Top Dead Center

,I'DC) of compression stroke (both valves closed). Correct

learance is 0.05-0.1mm. Adjust valve clearance as fol-

ws:

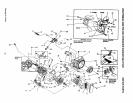

= Loosen the rocker arm jam nut. Use an allen wrench

to turn the pivot ball stud while checking clearance

between the rocker arm and the valve stem with a feeler

gauge (Fig. 27).

,, When valve clearance is correct, hold pivot ball stud

with allen wrench and tighten rocker arm jam nut with

crows foot. Tighten jam nut to 65-85 inch-pounds

torque. After tightening jam nut, recheck valve clear-

ance to make sure it did not change (Fig. 28).

NOZZLE MAINTENANCE

If the nozzle becomes restricted or clogged with foreign

materials, such as dirt, excessive pump pressure may

develop. A partially clogged nozzle can cause a pulsing

sensation during use. This generally is not a pump related

problem, but rather a clogged or partially restricted nozzle.

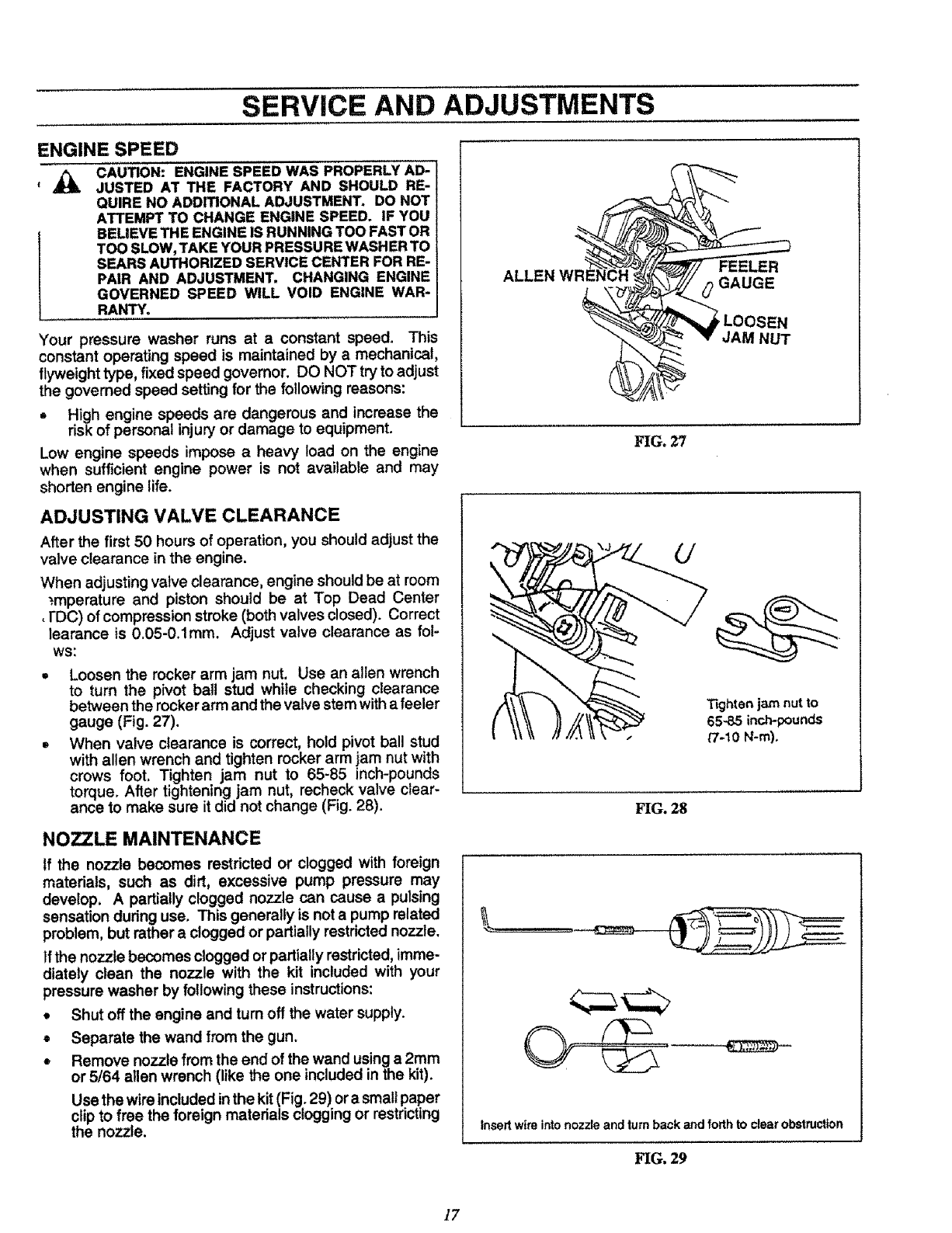

If the nozzle becomes clogged or partially restricted,imme-

diately clean the nozzle with the kit included with your

pressure washer by following these instructions:

• Shut off the engine and turnoff the water supply.

= Separate the wand from the gun.

,, Remove nozzle from the end of the wand using a 2ram

or 5/64 allen wrench (like the one included in the kit).

Use the wire included inthe kit (Fig. 29) or a smallpaper

clipto free the foreign materials clogging or restricting

the nozzle.

ALLEN

FEELER

GAUGE

',LOOSEN

JAM NUT

FIG. 27

Tighten jam nut to

65,.85 inch-pounds

_7-10 N-m).

FIG. 28

Insert wireintonozzle andturnback andforth toclearobstruction

FIG. 29

17