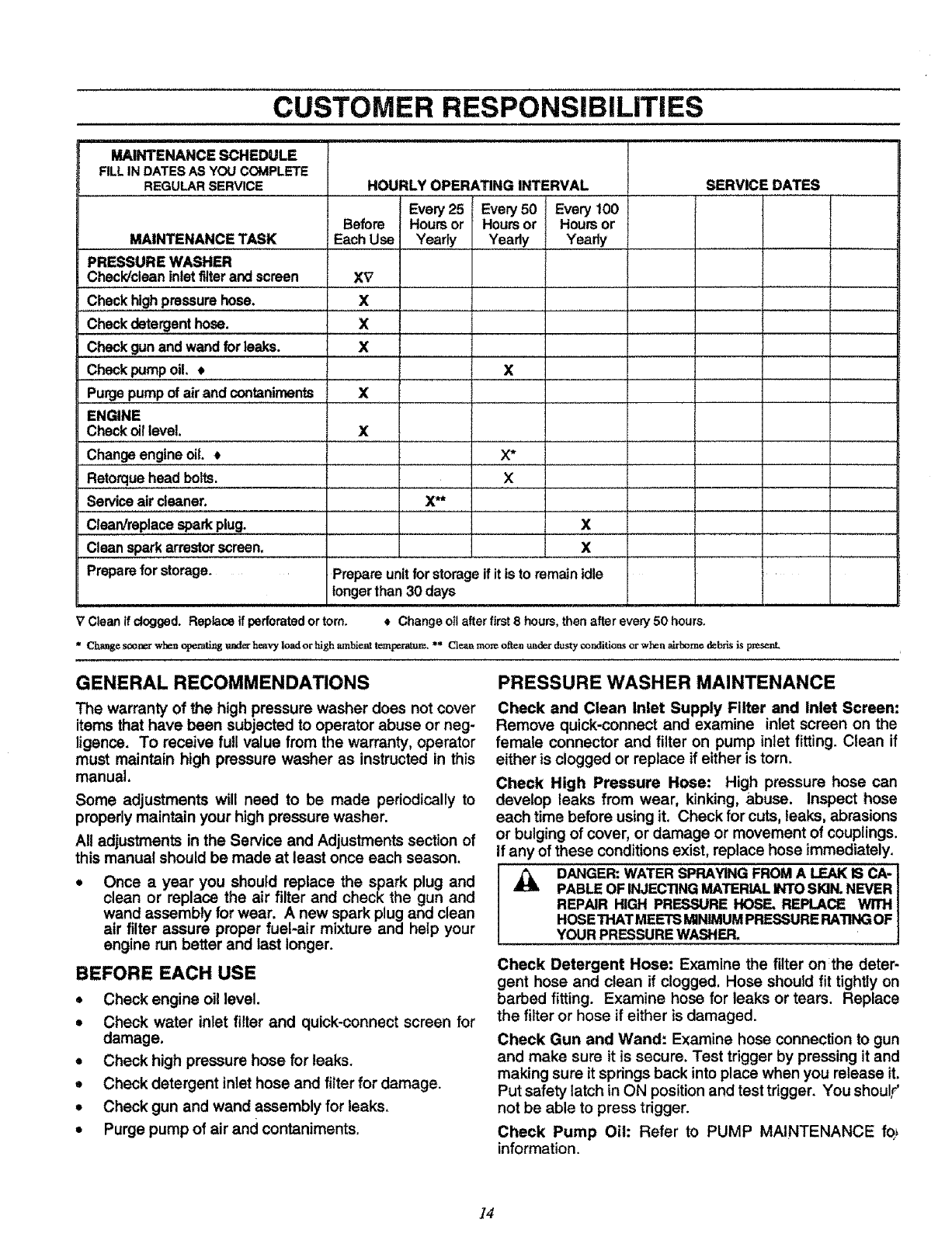

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

RLLINDATESASYOUCOMPLETE

REGULARSERVICE

Every25

Before Hoursor

MAINTENANCE TASK EachUse Yearly

PRESSURE WASHER

Check/cleaninletfilter andscreen XV

Checkhighpressurehose. X

Checkdetergenthose. X

Checkgunand wandfor leaks. X

Checkpumpoil. •

Purgepumpof airandcon_nirnents _ X ,

ENGINE

Check oillevel. X

Changeengine oil. • X*

Retorquehead bolts. X

Serviceair cleaner. X**

Clean/replacesparkplug.

Cleansparkarrestorscreen.

Preparefor storage.

HOURLY OPERATING INTERVAL

Every50 Every100

Hoursor Hoursor

Yeady Yeady

X

SERVICE DATES

X

X

Prepare unitfor storageifitisto remain idle

longer than30 days

V Cleanifdogged. Replaceifperforatedortorn. t Changeoilafterfirst8 hours,thenafterevery50hours.

*Change, scoam'when oporati_,g u_texheavyloadorhighambi_nt temperature. _* Cle_anrao_oft_n_m6vrdustyconditionsorwhenalrborncdebrisls pr_se_

GENERAL RECOMMENDATIONS PRESSURE WASHER MAINTENANCE

The warranty of the high pressure washer does not cover

items that have been subjected to operator abuse or neg-

ligence. To receive full value from the warranty, operator

must maintain high pressure washer as instructed in this

manual.

Some adjustments will need to be made periodically to

properly maintain your high pressure washer.

All adjustments in the Service and Adjustments section of

this manual should be made at least once each season.

Once a year you should replace the spark plug and

clean or replace the air filter and check the gun and

wand assembly for wear. A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check water inlet filter and quick-connect screen for

damage.

• Check high pressure hose for leaks.

t Check detergent inlet hose and fitter for damage.

= Check gun and wand assembly for leaks.

• Purge pump of air and contaniments.

Check and Clean Inlet Supply Filter and Inlet Screen:

Remove quick-connect and examine inlet screen on the

female connector and filter on pump inlet fitting. Clean if

either is clogged or replace ifeither is tom.

Check High Pressure Hose: High pressure hose can

develop leaks from wear, kinking, abuse. Inspect hose

each time before using it. Check for cuts, leaks, abrasions

or bulging of cover, or damage or movement of couplings.

If any of these conditions exist, replace hose immediately.

A DANGER:WATER SPRAYINGFROMA LEAKIS CA- I

PABLEOFINJECTINGMATERIALINTOSiON.NEVER [

REPAIR HIGH PRESSUREHOSE. REPLACE WITH

HOSETHATMEETSMINIMUMPRESSURERATINGOF

YOURPRESSUREWASHER,

Check Detergent Hose: Examine the filter on the deter-

gent hose and clean if clogged, Hose should fit tightly on

barbed fitting. Examine hose for leaks or tears. Replace

the filter or hose ifeither is damaged.

Check Gun and Wand: Examine hose connection to gun

and make sure it is secure. Test trigger by pressing it and

making sure itsprings back into place when you release it.

Put safety latch in ON position and test trigger. You shoulF

not be able to press trigger.

Check Pump Oil: Refer to PUMP MAINTENANCE fQ_

information.

]4