Hardware identification& TorqueSpecifications

Common Hardware Types

Hex Head Capscrew

C ((((((((((((((((((((){(((((((((((((((((( O

Carriage Belt

¢ (((((((((((((((((((()((((((((((((((({((((O

Washer

Lockwasher

HexNut

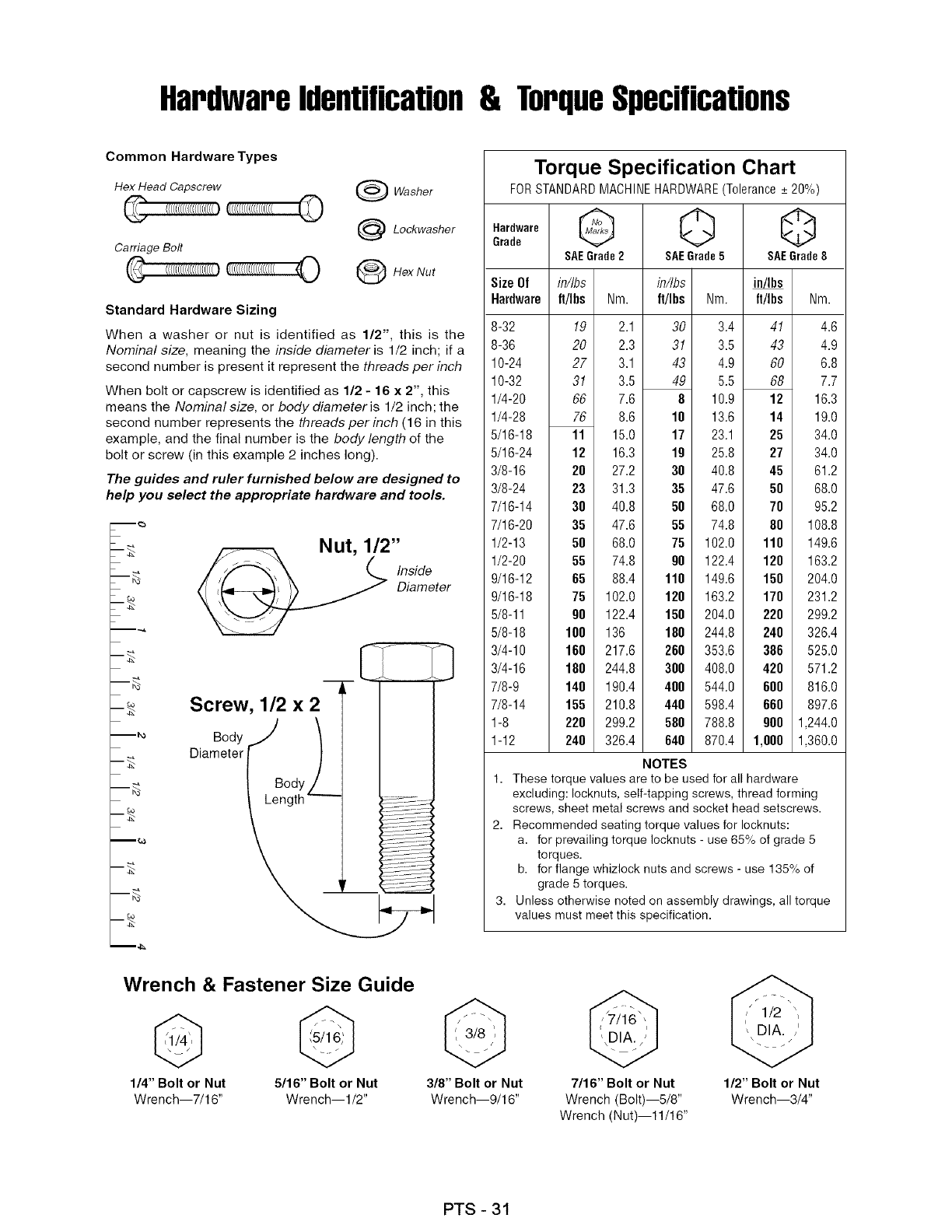

Standard Hardware Sizing

When a washer or nut is identified as 112", this is the

Nominal size, meaning the inside diameteris 1/2 inch; if a

second number is present it represent the threads per inch

When bolt or capscrew is identified as 112 - 16 x 2", this

means the Nominal size, or body diameter is 1/2 inch; the

second number represents the threads perinch (16 in this

example, and the final number is the body length of the

bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

m_

mr

-" Screw,

--_ Body

Diameter

m4_

Nut, 1/2"

Inside

Diameter

1/2x2 "

Length

}

Wrench & Fastener Size Guide

@

114" Bolt or Nut 5/16" Bolt or Nut

Wrench--7/16" Wrench--1/2"

Hardware

Grade

Torque Specification Chart

FORSTANDARD MACHINE HARDWARE (Tolerance _+20%)

© © ©

SAEGrade2 SAEGrade5 SAEGrade8

SizeOf

Hardware

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18

5/16-24

3/8-16

3/8-24

7/16-14

7/16-20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

7/8-9

7/8-14

1-8

1-12

in/Ibs

fifths Nm.

19 2.1

20 2.3

27 3.1

31 3.5

in/Ibs

ft/Ibs Nm.

30 3.4

31 3.5

43 4.9

49 5.5

in/Ibs

ft/Ibs Nm.

41 4.6

43 4.9

60 6.8

68 7.7

66 7.6 8

76 8.6 10

11 15.0 17

12 16.3 19

20 27.2 30

23 31.3 35

30 40.8 50

35 47.6 55

50 68.0 75

55 74.8 90

65 88.4 110

75 102.0 120

90 122.4 150

100 136 180

160 217.6 260

180 244.8 300

140 190.4 400

155 210,8 440

220 299.2 580

240 326.4 640

10.9 12 16.3

13.6 14 19.0

23.1 25 34.0

25.8 27 34.0

40.8 45 61.2

47.6 50 68.0

68.0 70 95.2

74.8 80 108.8

102.0 110 149.6

122.4 120 163.2

149.6 150 204.0

163.2 170 231.2

204.0 220 299.2

244.8 240 326.4

353.6 386 525.0

408.0 420 571.2

544.0 600 816.0

598.4 660 897.6

788.8 900 1,244.0

870.4 1,000 1,360.0

NOTES

1. These torque values are to be used for all hardware

excluding: Iocknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for Iocknuts:

a. for prevailing torque Iocknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

318" Bolt or Nut

Wrench--9/16"

7/16" Bolt or Nut

Wrench (Bolt)--5/8"

Wrench (Nut)--11/16"

112" Bolt or Nut

Wrench--3/4"

PTS - 31