38 – English

4

3

1

2

IMPORTANT INFORMATION

The area around the sealing collar must be

absolutely clean! If the hydrostatic oil is

contaminated with dirt, this can lead to a

shorter hydrostatic transmission

operational life.

Reparation instructions

Insert a garage jack under the hydrostatic trans-

mission and loosen its five holder screws.

• Lower the garage jack and pull out the

hydrostatic transmission.

• Installation of the hydrostatic transmission is

carried out in the reverse hydrostatic transmis-

sion removing order

• After fitting the brake wire and hydrostatic

transmission wires, check that they are

correctly adjusted (see “Inspection and

adjustment of brake wire” and “Inspection and

adjustment of speed control”). Check also the

oil level in the hydrostatic transmission, and top

up if necessary. Check the setting of the

neutral position switch on machines with

hydrostatic transmission, see ”Electrical

system\Microswitch neutral position”.

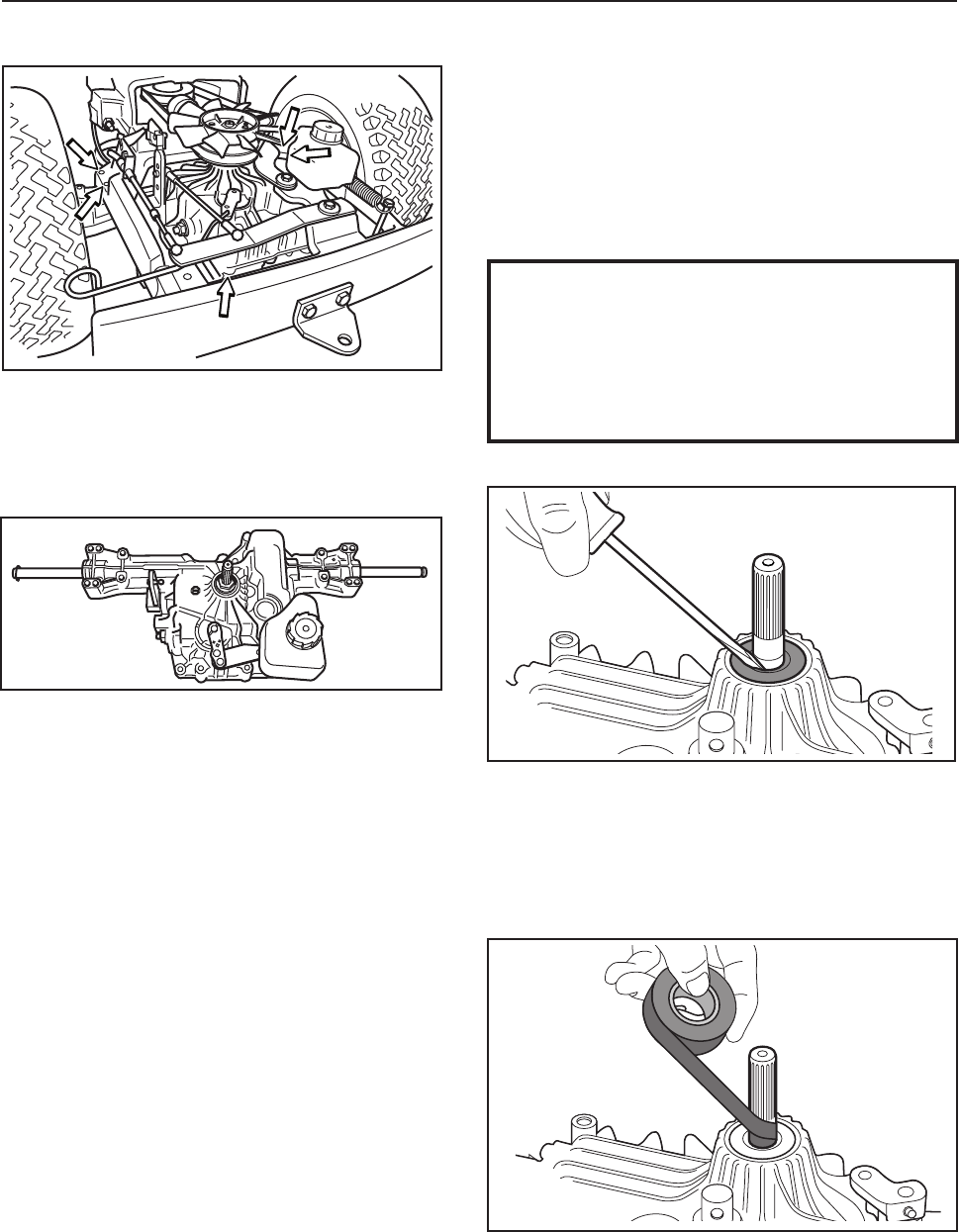

Replacing hydrostatic transmission axle

sealing collars

Sealing collar replacement - input axle

Remove the cooling fan, it is held by a circlip. Rem-

ove the pulley from the input axle by pulling it

upwards and then removing the circlip under the

pulley.

• Clean the input axle and the area around the

sealing collar of all dirt and rust.

• Insert a screwdriver between the sealing collar and

the axle and bend the sealing collar out of the axle

housing with a twisting motion.

• Wrap insulation tape around the input axle to

protect the new sealing collar from damage to

splines and grooves.

Start by wrapping from the bottom and continue

upwards over the axle until the entire axle is

wrapped in tape.

• Lubricate the axle and the inside of the new

sealing collar with grease so that the collar can

slide easily.