SAFETY WARNINGS AND INSTRUCTIONS: EXTENSION CORDS

Make sure your extension cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. The table shows the

correct size to use depending on cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord. If the

extension will be used outside, the cord must be suitable for outdoor work. The letters “WA”

on the cord jacket indicate that the cord is suitable for outdoor use.

SAVE THESE INSTRUCTIONS

ASSEMBLY / ADJUSTMENT SET-UP

WARNING: The guard must always be on the tool to protect the user.

NEVER OPERATE TOOL WITHOUT GUARD FIRMLY IN PLACE.

UNPLUG THE TOOL BEFORE ATTEMPTING TO ATTACH THE GUARD.

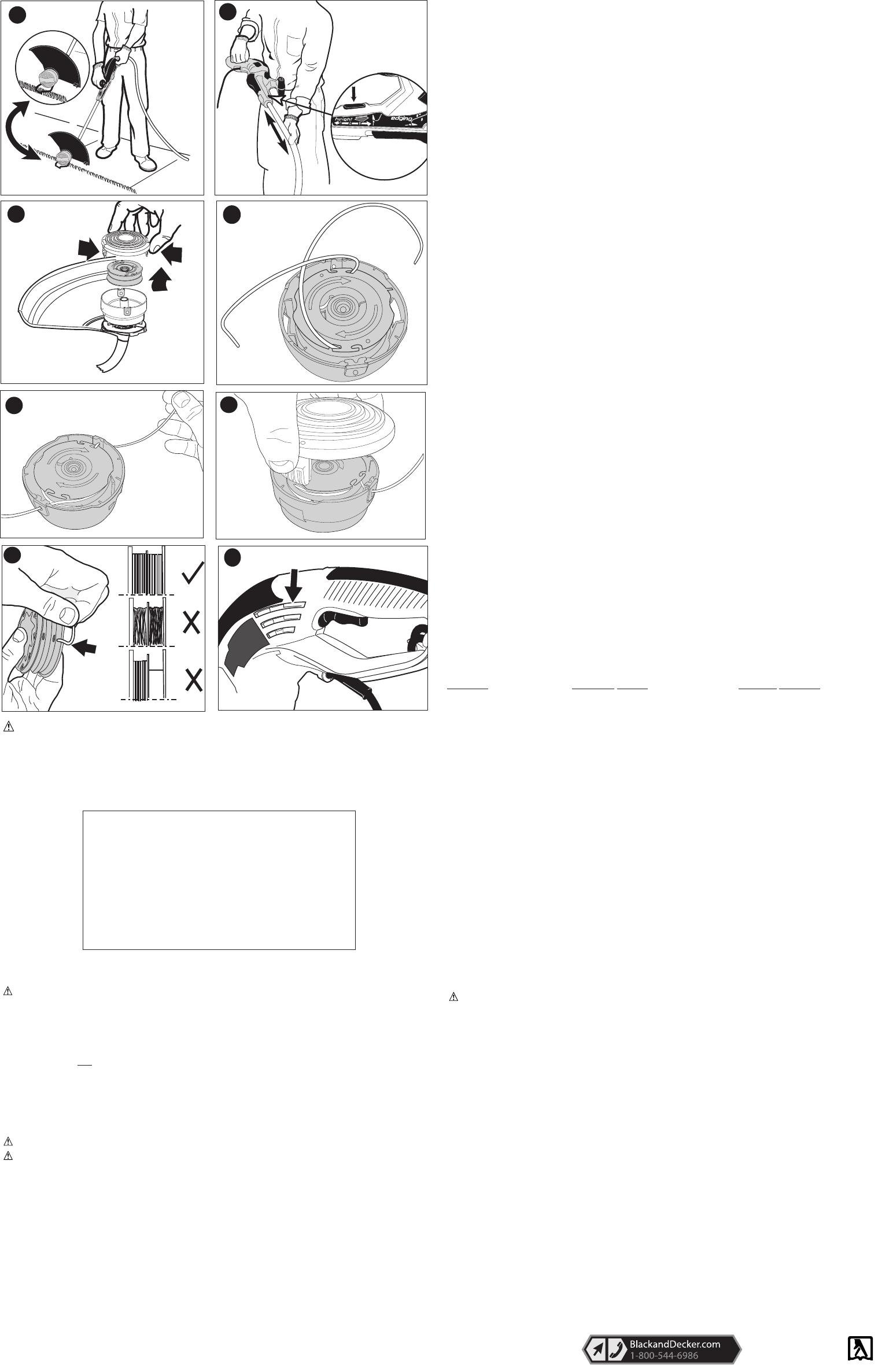

1. Position the open center of the guard over the line feed head (Figure 1).

2. Slide the guard into slot provided and tighten hex head screws with hex wrench included

(Figure 2).

3. The guard is not

intended to be removed once installed.

4. Once the guard is installed, remove the covering from the line cut-off blade, located on the

edge of the guard.

5. Adjust the length of the tube by pushing the button and moving the tube up or down as

shown in Figure 8.

6. Secure the extension cord with the cord retainer as shown in Figure 3.

OPERATING INSTRUCTIONS

CAUTION: ALWAYS WEAR EYE PROTECTION

CAUTION: Inspect area to be trimmed and remove any wire, cord, or string-like objects

which could become entangled in the rotating line or spool. Be particularly careful to avoid any

wire which might be bent outwardly into the path of the tool, such as barbs at the base of a

chain link fence.

• With the unit on, slowly swing the trimmer side to side as shown in Figure 5.

• To convert for maintenance edging, unplug the unit from the power source. Gently pull the

wire edge guide down into place as shown in Figure 7. Push the button and rotate the

tube 180° as shown in Figure 6. The tool will lock in the edger position. Unit is shipped in

the edging position.

• To operate as a maintenance edger, position the trimmer above the surface as shown in

Figure 7.

• Return to the trimming position by unplugging the unit from the power source, pushing the

button and rotating the tube back 180°. The tool will lock in the trimmer position. When

using the tool put up the wire edge guide to the original position, out of the way.

CUTTING LINE

LINE FEEDING

Your trimmer uses .080 in. (2mm) diameter, ROUND nylon line to cut grass and weeds

quickly and easily. During use, the tips of the nylon lines will become frayed and worn

and the special self feeding line hub will automatically feed and trim a fresh length of line.

Cutting line will wear faster and require more feeding if the cutting or edging is done

along sidewalks or other abrasive surfaces or heavier weeds are being cut. The

advanced automatic line feeding mechanism senses when more cutting line is needed

and feeds and trims the correct length of line whenever its required. DO NOT BUMP unit

on ground in attempt to feed line or for any other purposes.

CLEARING JAMS AND TANGLED LINES

From time to time, especially when cutting thick or stalky weeds, the line feeding hub

may become clogged with sap or other material and the line will become jammed as a

result. To clear the jam, follow the steps listed below.

1. Unplug the trimmer.

2. Press the release tabs on the line hub cap, as shown in Figure 9 and remove the cap by

pulling it straight off.

3. Pull the nylon line spool out and clear any broken line or cutting debris from the spool area.

(YOU DO NOT HAVE TO REMOVE THE CENTER SCREW TO REMOVE THE SPOOL).

4. Place spool and line into spool housing with lines “parked” in slots provided as shown in

figure 10.

5. Insert the line end through the appropriate holes in the spool hub. Pull slack line through

until it pulls out of the holding slots as shown in Figure 11.

6. Press the spool down GENTLY and rotate it until you feel it drop into place and then push

to snap into place. (When in place, the spool will turn a few degrees left and right freely).

Take care to keep the line from becoming trapped under the spool.

7. Snap the hub cap back on as shown in figure 12 by depressing lugs and pressing into

spool housing. NOTE: Make sure that cover is fully positioned, listen for two audible

clicks to ensure both lugs are correctly located. Power the tool on. In a few seconds or

less youʼll hear the nylon line being cut automatically to the proper length.

SPOOL OR LINE REPLACEMENT (Use .080 in. diameter ROUND line only)

1. Unplug the trimmer. Press the release tabs on the line hub cap, as shown in Figure 9

and remove the cap by pulling it straight off.

2. Remove the spool from the tool and remove and discard all line on the spool.

3. Choose either OPTION 1 or OPTION 2.

OPTION 1: ACCESSORY REPLACEMENT SPOOL

Use Black & Decker replacement spool Model No. DF-080. Install following instructions

under “ SPOOL OR LINE REPLACEMENT“ #1 through #6, discarding old spool for Step 3

and using new spool in subsequent steps.

O

PTION 2: REWINDING SPOOL USING BULK LINE

B

ulk line for your trimmer/edger is available at extra cost from your local dealer or

B

lack & Decker Service Center. Install following instructions under “SPOOL OR LINE

R

EPLACEMENT” #1 through #6, performing the following steps for Step 3.

(

Use .080 in. diameter ROUND line only)

a. Your line spool for this product has two (2) wind areas for line. Wind line in one area first

and then in the other. NOTE: For best results, wind line onto the outer portion of the spool

(side with arrows) first.

b. Fold over nylon line about 3/4 in. (19mm) from the end to form a “hook” as shown in

Figure 13. Insert the hooked end of the line into the slot on the inside of the spool.

c. Snugly and evenly wind the bulk line onto the spool in the direction of the arrow on the

spool until the line builds up to the notches in the spool rim. Do not overfill spool. Repeat

for the other wind area.

4. Place spool and line into spool housing with lines “parked” in slots provided as shown in

figure 10.

5. Insert the line ends through the holes in the spool hub. Pull slack line through until it

pulls out of the holding slots as shown in Figure 11.

6. Press the spool down GENTLY and rotate it until you feel it drop into place and then push

to snap into place. (When in place, the spool will turn a few degrees left and right freely).

Take care to keep the line from becoming trapped under the spool.

7. Snap the hub cap back on as shown in figure 12, by depressing lugs and pressing into

spool housing. NOTE: Make sure that cover is fully positioned, listen for two audible

clicks to ensure both lugs are correctly located. Power the tool on. In a few seconds or

less youʼll hear the nylon line being cut automatically to the proper length.

• For trouble free feeding and best results, only use Black & Decker replacement

spools with dual 0.080 inch line. Black & Decker replacement spool model number

DF-080.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

ACCESSORIES

Use Black & Decker replacement spool Model No. DF-080.

Reload nylon line (either bulk or prewound replacement spool) as shown in this manual.

• USE ONLY .080 in. (2mm) DIAMETER NYLON MONOFILAMENT LINE. Do not use

serrated or heavier gauge line, as they will overload the motor and cause overheating.

The unit only functions properly with 0.080 in. (2mm) diameter nylon monofilament line.

This line is available at your local dealer or authorized service center.

WARNING: The use of any accessory not recommended by Black & Decker for use with

this tool could be hazardous.

SERVICE INFORMATION

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-544-6986 or visit www.blackanddecker.com

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailerʼs policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required.Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state or province to province. Should you

have any questions, contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, check country specific warranty information contained in the

packaging, call the local company or see the website for warranty information.

7

8

9

10

13

14

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in. • Plug tool into a working outlet.

• Circuit fuse is blown. • Replace circuit fuse. (If the product

repeatedly causes the circuit fuse to

blow, discontinue use immediately and

have it serviced at a Black & Decker

service center or authorized servicer.)

• Circuit breaker is tripped. • Reset circuit breaker. (If the product

repeatedly causes the circuit breaker to

trip, discontinue use immediately and

have it serviced at a Black & Decker

service center or authorized servicer.)

• Cord or switch is • Have cord or switch replaced at Black

damaged. & Decker Service Center or Authorized

Servicer

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

1

2

1

1

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended